You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Harrison M300 Rebuild

- Thread starter scottmk1

- Start date

scottmk1

Forum Supporter

- Messages

- 2,000

- Location

- Scotland

Ok thanks. I have the bed stripped bare, saddle, cross slide, top slide & tail stock stripped. The head, screw cutting gearbox and apron are off but not stripped so should be pretty much ready.

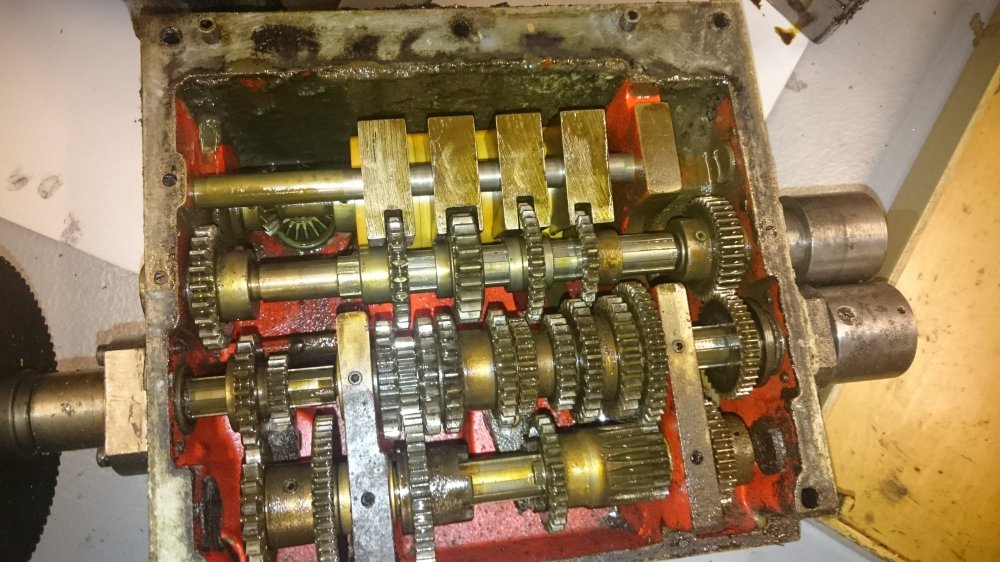

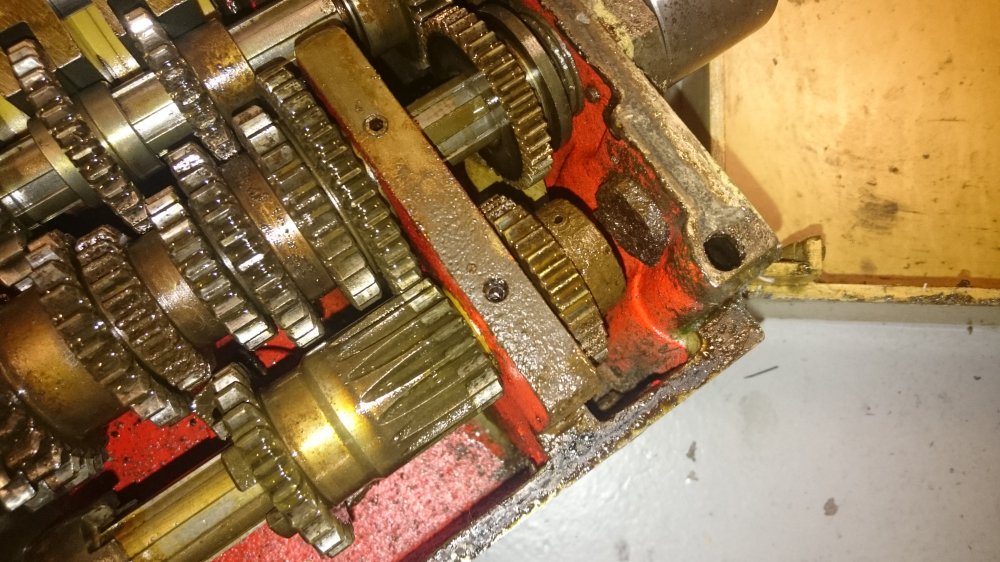

The screw cutting gearbox was manky inside, with some rust in places. I'm sure it will be fine though.

The screw cutting gearbox was manky inside, with some rust in places. I'm sure it will be fine though.

They are usually made of ductile CI, Meehanite if you can source some easily. Any old iron will do the job if you can find something close enough in size to cut up and have someone grind for you.Got the top slide in bits now. Unfortunately the gib strip has a kink in at the tool post end, so I think it will need a new one. Anyone know what sort of steel they are usually made from?

View attachment 74079

I guess that you will be a busy man with this job Scott. Images of what you have, what you have had worked on and what you have assembled are appreciated and valued by people owning machine tools of the vintage sort.Thanks Ian, I have sourced a good used gib along with a few other parts. The bulk of the machine is away to get re ground and I'm now in the process of gather the parts I require.

If you find time then please to post any images of work done. For people not fancying a contemporary Chinese product there is much value in the experience of others who put effort into the older and generally more solid metal.

scottmk1

Forum Supporter

- Messages

- 2,000

- Location

- Scotland

Hi Ian. Thanks for the comments, I intend on posting more info & pics as work gets done, however since the last post not much has happened. The bulk of the machine is still away getting the ways ground and all I have done since then is clean a few parts. Next up will probably be stripping the apron so I will get some pics of that.

scottmk1

Forum Supporter

- Messages

- 2,000

- Location

- Scotland

Hi, I will post more once I've got more done, at present it's all stripped & bits away for grinding. I have got hold of some spares that I needed & continue to hunt for more.

I need to paint it too, so what's the best machine paint that doesn't cost the earth?

@Shox Dr the grinding is being done by Brian at Slideway Services.

I need to paint it too, so what's the best machine paint that doesn't cost the earth?

@Shox Dr the grinding is being done by Brian at Slideway Services.

Spark plug

Member

- Messages

- 4,062

- Location

- Durham, England

Cromadex is very good machenery paint don't know how mutch it is these days, or if you have a local supplier.

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,993

- Location

- East Yorkshire

Keep up the posts, they are most interesting. I am keen to hear more about the whole regrinding process and how it works.

...grinding is being done by Brian at Slideway Services.

He uses really really big grinders, topslide for a M300 been cut, to give you the scale, that picture was taken in his old shop down the road, from where he is now. One of his machines was from Bridgeport in Bridlington, one of only two in the world.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,487

- Location

- Don't ask questions

It's hard to tell on a phone, but is that mag base on a compound sine table? I'd love to look around his workshopHe uses really really big grinders, topslide for a M300 been cut, to give you the scale, that picture was taken in his old shop down the road, from where he is now. One of his machines was from Bridgeport in Bridlington, one of only two in the world.

.

.scottmk1

Forum Supporter

- Messages

- 2,000

- Location

- Scotland

Ok, getting on with this again after some other stuff needed doing.

I re measured my worn out cross feed screw, it's 5/8" 10tpi acme. It has the Gammet dual reading dials which have been well abused but that's another story.

I have acquired another cross feed screw, apparently from an M300, but it's different than the one that I removed. In the picture the top one is what came off, the bottom two piece is the newly acquired one. They are the same thread and the cross feed nuts are the same shape/size/design.

Anyone able to ID the two piece screw? It is in good condition so I'd like to use it, but if it means chopping up I may sell it to someone that needs it for their machine.

I re measured my worn out cross feed screw, it's 5/8" 10tpi acme. It has the Gammet dual reading dials which have been well abused but that's another story.

I have acquired another cross feed screw, apparently from an M300, but it's different than the one that I removed. In the picture the top one is what came off, the bottom two piece is the newly acquired one. They are the same thread and the cross feed nuts are the same shape/size/design.

Anyone able to ID the two piece screw? It is in good condition so I'd like to use it, but if it means chopping up I may sell it to someone that needs it for their machine.