You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brazing fail

- Thread starter GraemeVW

- Start date

Smallfry

HE's Spartacus.

- Messages

- 2,218

- Location

- Kent UK

Dunno, I watched a mate (sadly now gone) do it many times with OA with steel of various thicknesses. He always used to get the subject red, dip the rod onto a big rusty square tin of white flux powder, and it always seemed to take, and then chase the molten brass around with the flame.Surprisingly, heat wasn't an issue. I had it pretty much yellow!

Brad93

Member

- Messages

- 19,078

- Location

- Essex, United Kingdom

Yellow is probably too hot. Warm Red is all you need. Dull red is about 800 degrees.

If your metal is too hot the zinc will boil off immmediately and the filler will ball up and just roll around on the surface. Also you'll pass the working temperature range of the flux

If your metal is too hot the zinc will boil off immmediately and the filler will ball up and just roll around on the surface. Also you'll pass the working temperature range of the flux

you can overheat things for braze , and the rods just ball and roll off ... its not just about heating things as hot as you can get them ,,, i prefer unfluxed rods and a tin of flux as you can see what the rods doing long before it just vanishes.

snap ,,,,Yellow is probably too hot. Warm Red is all you need. Dull red is about 800 degrees.

If your metal is too hot the zinc will boil off immmediately and the filler will ball up and just roll around on the surface. Also you'll pass the working temperature range of the flux

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

I did have it hotter than I expected to have to, but the rods just weren't working at any lower temperature. No way it would work when the iron was red. Only just started to show signs of maybe working at orange and I went to yellow to see.

From the moment it started to glow I was trying to see if it would melt the rods, or if molten rod would wet the surface.

I think I had it too hot for the flux though, agreed.

I have cleaned the piece up, and I'll try on something else to see if I can get the rods to work, but I suspect, no matter what the advert says, they are tig rods.

From the moment it started to glow I was trying to see if it would melt the rods, or if molten rod would wet the surface.

I think I had it too hot for the flux though, agreed.

I have cleaned the piece up, and I'll try on something else to see if I can get the rods to work, but I suspect, no matter what the advert says, they are tig rods.

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

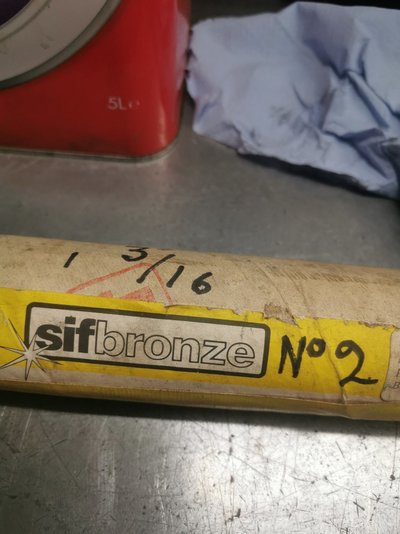

Went to my local welding suppliers today and they couldn't help.Think We have some old Sif rods will look over week end might have other makes as well

Would be free except for post

If you had a couple of rods, that would be amazing!

Btw, many years ago, did you have a Thames (500e) rebuild thread going on retro rides?

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

Just tried a small cast iron test piece.

Having to get it glowing yellow before the work will even think about melting the rod.

I'm almost certain these are tig rods Nd don't have the 875° stated melting point.

Watched a couple of YouTube vids and they are melting rod in with the iron glowing red. This has absolutely no chance of doing that!

Having to get it glowing yellow before the work will even think about melting the rod.

I'm almost certain these are tig rods Nd don't have the 875° stated melting point.

Watched a couple of YouTube vids and they are melting rod in with the iron glowing red. This has absolutely no chance of doing that!

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

Just had a plan.

I just put a small bit of brass and a small bit of these rods in a crucible.

Same cross section, same length, and heated them if anything the brass balled up first!

Brass is what, 930° brazing rods should be somewhere around the 850 mark right? And these must be about 950+

I just put a small bit of brass and a small bit of these rods in a crucible.

Same cross section, same length, and heated them if anything the brass balled up first!

Brass is what, 930° brazing rods should be somewhere around the 850 mark right? And these must be about 950+

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

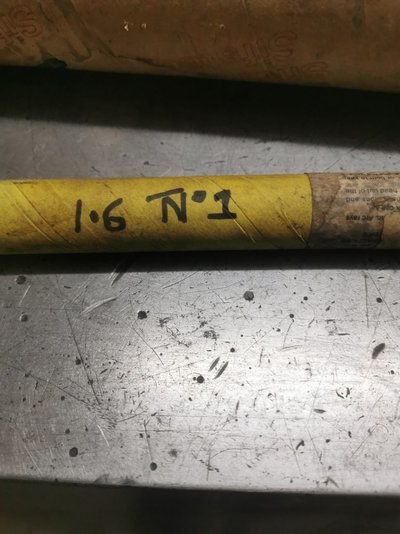

We all like pics. Bit of colour to brighten the place up.

I had to get this bit of spanner glowing bright yellow for the braze to actually take.

The small cast iron sample I tried I gave up before it went.

So it is POSSIBLE, just needs 1000° to do it

Edit... I only bothered to clean the last 1/4 of it, I wasn't trying to braze it while filthy!

Edit 2

Managed to get some to look like it's flowed onto a bit of old cast iron

Again, was glowing bright yellow though and wasn't very convincing.

Thought it hadn't worked, but it had all flowed onto the other side

I had to get this bit of spanner glowing bright yellow for the braze to actually take.

The small cast iron sample I tried I gave up before it went.

So it is POSSIBLE, just needs 1000° to do it

Edit... I only bothered to clean the last 1/4 of it, I wasn't trying to braze it while filthy!

Edit 2

Managed to get some to look like it's flowed onto a bit of old cast iron

Again, was glowing bright yellow though and wasn't very convincing.

Thought it hadn't worked, but it had all flowed onto the other side

Last edited:

GraemeVW

Member

- Messages

- 1,663

- Location

- Chesterfield

Thank you.

Yep, not enough rusty old ford in that picture

Cool though!

brightspark

Member

- Messages

- 41,199

- Location

- yarm stockton on tees

dont exactly know what gas grade brazing rods i use i got a big bunch given 50 years ago  i just know they flow well and do the job

i just know they flow well and do the job

i just know they flow well and do the job

i just know they flow well and do the jobzeppelin builder

Member

- Messages

- 2,174

- Location

- peoples republic of scotland

high strength , can be used as a wear resisting overlay too