You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BS 4872 Coding

- Thread starter SiPMerlin150

- Start date

SiPMerlin150

Member

- Messages

- 987

- Location

- Sunshine Coast, Queensland

Looking good, you just need to keep everything a bit tighter, on the first photo it looks as if you strayed out onto the bottom plate a bit far, with a bit more practise you'll have it cracked

Great stuff, I'll keep at it. I've been told the throat of the weld shouldn't exceed the total width of the material welded?

wheresmejumper

Banned

- Messages

- 2,626

that doesnt look too bad at all,a lot better than some of the test pieces that i saw handed up to be examined!

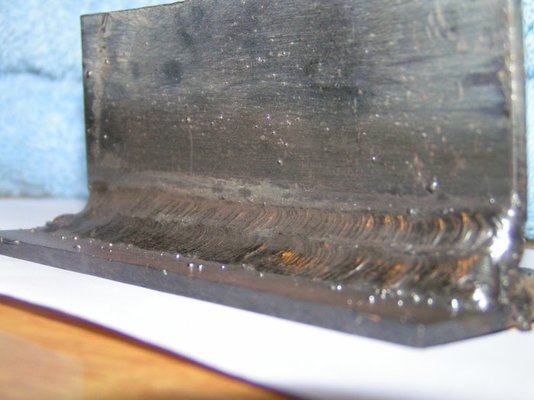

its hard to judge with a short run,but you need to have a very consistent amount of the second pass visible-the width of a rod is the norm-so around 3mm.you need all 3 runs dead straight for this to be right the whole way accross

practicing on longer pieces will highlight variances more easily

its hard to judge with a short run,but you need to have a very consistent amount of the second pass visible-the width of a rod is the norm-so around 3mm.you need all 3 runs dead straight for this to be right the whole way accross

practicing on longer pieces will highlight variances more easily

wheresmejumper

Banned

- Messages

- 2,626

cutting the workpiece at a few points will let you compare weld profile too

Rrunnach

Member

- Messages

- 1,127

- Location

- Scotland

I'd say 4mm is a bit on the wee side for three run pass, but if this is all that is available, then good enough.

You really need to back track 4-5mm before ceasing the arc, this will eliminate craters at end of run, craters can be notorious for crater cracking, as one member in here mentioned recently, he dipped

You really need to back track 4-5mm before ceasing the arc, this will eliminate craters at end of run, craters can be notorious for crater cracking, as one member in here mentioned recently, he dipped

chevy2

Member

- Messages

- 1,631

- Location

- Herts.

When i worked as a full time welder/fabricator we had about 4-5 extra guys employed during some busy periods, all coded welders.

I think we were unlucky as there wasn't one there that had any real 'general' skills,

They were all probably very good but only in what they were coded for?

I think we were unlucky as there wasn't one there that had any real 'general' skills,

They were all probably very good but only in what they were coded for?

SiPMerlin150

Member

- Messages

- 987

- Location

- Sunshine Coast, Queensland

Heres a couple of additional runs, one lap joint and a triple pass tee fillet.

Will do more tommorow, I'm back in the welding college doing the mma level 2 test pieces, so once i've gotten my test piece out of the way, I shall tack up some 6mm plate and do some multi pass runs... Be warned though, They've supplied us with some cheapo crap rods, the 2.5's aren't bad, but the 3.2's are crap! They've got the good 'uns locked away... not surprisingly as they aren't cheap, but I will try and lift some lo-hi's out of the oven to use.

These are the cheapo rods they have us using. They don't seem to like AC....the only 6013 that won't run right on a buzzbox!

I'll try 'em on AC at the college tomoz to see if its a OCV issue. More than likely.

I haven't seen this make before which makes me all the more suspicious that they aren't a reputable brand...

Will do more tommorow, I'm back in the welding college doing the mma level 2 test pieces, so once i've gotten my test piece out of the way, I shall tack up some 6mm plate and do some multi pass runs... Be warned though, They've supplied us with some cheapo crap rods, the 2.5's aren't bad, but the 3.2's are crap! They've got the good 'uns locked away... not surprisingly as they aren't cheap, but I will try and lift some lo-hi's out of the oven to use.

These are the cheapo rods they have us using. They don't seem to like AC....the only 6013 that won't run right on a buzzbox!

I'll try 'em on AC at the college tomoz to see if its a OCV issue. More than likely.

I haven't seen this make before which makes me all the more suspicious that they aren't a reputable brand...

Last edited:

SiPMerlin150

Member

- Messages

- 987

- Location

- Sunshine Coast, Queensland

The fillet is looking a lot better, the lap joint is a bit peaky and you're not getting a smooth transition at the toe of the weld, try playing around with power settings, angles and travel speeds a bit

Yeah the lap joint isn't a major strong point, its one of those areas I need to have more practise on. I did some in 6mm plate with 3.2mm 6013 started off at 80 amps, and played around till I got to 100 amps and began producing some alright looking runs. I found its a delicate balnce between melting that corner in as the two plates heat up at different rates.

wheresmejumper

Banned

- Messages

- 2,626

angle the rod towards the lower plate?

i seem to run them hotter,120ish for flat.we were given budget rods for a week,Geko.slag was a right effort to get off.i wouldnt mind but the good rods,Oerlikon,they were getting for a quid per kilo!

i seem to run them hotter,120ish for flat.we were given budget rods for a week,Geko.slag was a right effort to get off.i wouldnt mind but the good rods,Oerlikon,they were getting for a quid per kilo!

Last edited:

SiPMerlin150

Member

- Messages

- 987

- Location

- Sunshine Coast, Queensland

angle the rod towards the lower plate?

i seem to run them hotter,120ish for flat.we were given budget rods for a week,Geko.slag was a right effort to get off.i wouldnt mind but the good rods,Oerlikon,they were getting for a quid per kilo!

Yeah, same here, they told us to set amps at 90? which is on the low side for a 3.2 doing 6mm plate... so i knocked it up to 100 and it ran much better, (the side of the packed recommend 110-130 amps for 'em..

oilcooled :)

Pipe Welder, Mechanical engineer

- Messages

- 984

- Location

- Ireland

90 is very cold, 115 is normal i could do it vertical at that. Better off way too hot than too cold, you could do it at 150 no problem

SiPMerlin150

Member

- Messages

- 987

- Location

- Sunshine Coast, Queensland

90 is very cold, 115 is normal i could do it vertical at that. Better off way too hot than too cold, you could do it at 150 no problem

Yeah, They ran well, but only because the plate was already hot, and up at higher amps, the weld beads went very flat and were swirly in appearance, and the plate was glowing orange.

It was at 113amps that seemed to be the magic number. It was only 4mm plate too.

I have completed all of my test pieces, now, and at the moment I'm not sure which one will be dye penentration tested. Once the course is up, they allow us to take our test pieces away with us, so photographs will be posted up here.

The rest of the afternoon was spent to allow other students to catch up, whilst my test pieces were out on the bench cooling.

I know, the academy college know and the students know that I'm miles ahead of the other students. This wouldn't be possible if I hadn't joined this great forum and took lots of advice from many members!

oilcooled :)

Pipe Welder, Mechanical engineer

- Messages

- 984

- Location

- Ireland

Didnt realise it was a 4 mm plate want to be moving pronto, im on a full time day course atm cause I'm welding years with no codes, tests next week. 12 mm to 10mm t fillet mig, 6 mm t fillet mma and 3 mm mild streel stainless steel and alu t fillet tig.

SiPMerlin150

Member

- Messages

- 987

- Location

- Sunshine Coast, Queensland

Didnt realise it was a 4 mm plate want to be moving pronto, im on a full time day course atm cause I'm welding years with no codes, tests next week. 12 mm to 10mm t fillet mig, 6 mm t fillet mma and 3 mm mild streel stainless steel and alu t fillet tig.

Thats ok, I should of fully explained.

Thats a chunky Tee fillet to do with mig. Are you using 1mm wire? That will take some time to do. Good luck! I'm sure you will pass with flying colours!

Thats a chunky Tee fillet to do with mig. Are you using 1mm wire? That will take some time to do. Good luck! I'm sure you will pass with flying colours!

I'm not too sure on what codes I want to pursue. I want to train up for 6G but costs and practise time will hit my wallet big time. Jobs are a little sketchy too at the moment. Most places are quiet at this time of year. I may do my B.S 4872 initially, i know its not much by any standard, but I guess it seperates the apprentices from the more experienced, newbies.

wheresmejumper

Banned

- Messages

- 2,626

Didnt realise it was a 4 mm plate want to be moving pronto, im on a full time day course atm cause I'm welding years with no codes, tests next week. 12 mm to 10mm t fillet mig, 6 mm t fillet mma and 3 mm mild streel stainless steel and alu t fillet tig.

is that FAS Basic Welding?

oilcooled :)

Pipe Welder, Mechanical engineer

- Messages

- 984

- Location

- Ireland

Ya its a fair size, bit needed with all penetration issues with Mig, and that's what you have to prove, no i use 0.8 mm wire actually. I know the way. Next full time course over here is intermediate and its all plate butt welding in vertical position, with e6010 aond tig roots etc, its 3 months full time, then 4 mono the advanced pipe welding. Once you learn tig and get good, your mma will come up a gear automatically

SiPMerlin150

Member

- Messages

- 987

- Location

- Sunshine Coast, Queensland

Ya its a fair size, bit needed with all penetration issues with Mig, and that's what you have to prove, no i use 0.8 mm wire actually. I know the way. Next full time course over here is intermediate and its all plate butt welding in vertical position, with e6010 aond tig roots etc, its 3 months full time, then 4 mono the advanced pipe welding. Once you learn tig and get good, your mma will come up a gear automatically

I'm coming to the end of my Nvq level 2, which has been spread out over the course of a year, first section MIG, 3 test pieces, and writeups, Second section being mma, again 3 test pieces, and writeups, and finally TIG with 3 test pieces and writeups. Between these units are coursework on health & safety, action on fire prevention, recognising warning signs, dangers and risks associated with welding. Gas cylinder safe handling, use of cylinder lifts, machine use and problem solving, and industrial safey awareness.

I'm yet to do the TIG section, and I've never had chance to use a TIG setup. So this'll be interesting

oilcooled :)

Pipe Welder, Mechanical engineer

- Messages

- 984

- Location

- Ireland

You will visit the bench grinder many times the first week sharpening tungstens, but tig welding is all about teaching the wire feed to your bad hand and tig revolves around being good at feeding. You will get there very enjoyable like stick, not boring like Mig welding

but tig welding is all about teaching the wire feed to your bad hand and tig revolves around being good at feeding. You will get there very enjoyable like stick, not boring like Mig welding  sounds like a good course

sounds like a good course

but tig welding is all about teaching the wire feed to your bad hand and tig revolves around being good at feeding. You will get there very enjoyable like stick, not boring like Mig welding

but tig welding is all about teaching the wire feed to your bad hand and tig revolves around being good at feeding. You will get there very enjoyable like stick, not boring like Mig welding  sounds like a good course

sounds like a good courseSiPMerlin150

Member

- Messages

- 987

- Location

- Sunshine Coast, Queensland

You will visit the bench grinder many times the first week sharpening tungstens,but tig welding is all about teaching the wire feed to your bad hand and tig revolves around being good at feeding. You will get there very enjoyable like stick, not boring like Mig welding

sounds like a good course

Fortunately I can weld great with one hand, and not so bad with my other

But I can see my right hand doing the wire feeding.

They'll have plenty of tungstens to keep me going !

I'm a little confused on the TIG thing, the torch, is it a trigger like the MIG on and off? Or is it a stepping switch like say, an accelerator pedal of a car, the more you squeeze in and hold, the more power?

Can't you tell I haven't even picked up a TIG torch before?

Can't you tell I haven't even picked up a TIG torch before?