You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clarke SE16C150 - pump rebuild tips

- Thread starter gasket999

- Start date

gasket999

getting there...

- Messages

- 355

- Location

- Manchester, UK

Next, 6 nuts (well they're studs with nuts on the end - some studs came out) hold the cylinders to the crankcase. The pistons needed a light tap with a hammer handle at the end in order to come out completely.

Then on to inspecting the bottom end for damage (by this point I'd already cleaned as much of the crud from the top of the pistons as I could with a rag and some very gently scraping):

Then on to inspecting the bottom end for damage (by this point I'd already cleaned as much of the crud from the top of the pistons as I could with a rag and some very gently scraping):

Last edited:

gasket999

getting there...

- Messages

- 355

- Location

- Manchester, UK

General condition:

It looks grubby and horrible but it isn't bad at all.

The paint hasn't got past the top of the pistons (incidentally the pistons and con rods are aluminium).

The bottom end seems fine - the bearings are nice and free - there are two main bearings at each end of the crank which are held into the crankcase with a cast iron plate at each end and there are (obviously) two big end bearings.

It looks grubby and horrible but it isn't bad at all.

The paint hasn't got past the top of the pistons (incidentally the pistons and con rods are aluminium).

The bottom end seems fine - the bearings are nice and free - there are two main bearings at each end of the crank which are held into the crankcase with a cast iron plate at each end and there are (obviously) two big end bearings.

gasket999

getting there...

- Messages

- 355

- Location

- Manchester, UK

Condition of bores and pistons:

There is one mark at the end of one bore - no idea where its come from - while its piston was scraped in to places, there was a wasn't an exactly-corresponding mark on the piston skirt.

The above mentioned piston has a few scrapes on one side - however I have no reason to think these have come from the paint, these could have been in place before assembly or made during its bedding in period.

The piston rings are all unmarked - there are three on each piston.

One piston ring - the upper most of one - does not run freely - its a bit jammed as if there is corrosion or grit underneath it.

There is one mark at the end of one bore - no idea where its come from - while its piston was scraped in to places, there was a wasn't an exactly-corresponding mark on the piston skirt.

The above mentioned piston has a few scrapes on one side - however I have no reason to think these have come from the paint, these could have been in place before assembly or made during its bedding in period.

The piston rings are all unmarked - there are three on each piston.

One piston ring - the upper most of one - does not run freely - its a bit jammed as if there is corrosion or grit underneath it.

Last edited:

gasket999

getting there...

- Messages

- 355

- Location

- Manchester, UK

Oh and all of the above took about 10 mins.

Course of action:

I think it generally just needs thoroughly cleaned and put back together with new gaskets. The piston surfaces will need to be scrubbed and probably polished so get rid of any scratches made during cleaning - white spirit has removed as much as it can - I was thinking about a non-scratch kitchen sponge with the white abrasive surface.

However, in order to do the job properly I would want to remove the crank and undo the big end caps - there is all sorts of crud in the bottom of the crankcase and I have to assume there is grit in everything. I'll also need to release at least one piston ring (the sticky one) in order to clean underneath it.

So…

Hope this is helpful to other forumers!

Course of action:

I think it generally just needs thoroughly cleaned and put back together with new gaskets. The piston surfaces will need to be scrubbed and probably polished so get rid of any scratches made during cleaning - white spirit has removed as much as it can - I was thinking about a non-scratch kitchen sponge with the white abrasive surface.

However, in order to do the job properly I would want to remove the crank and undo the big end caps - there is all sorts of crud in the bottom of the crankcase and I have to assume there is grit in everything. I'll also need to release at least one piston ring (the sticky one) in order to clean underneath it.

So…

- Once I've carefully dismantled everything, what can I reuse and what is good practice to replace?

- If I remove the piston rings to clean underneath, can I reuse them?

- Should I hone the bores to get rid of/reduce the small bit of damage - if so will this mean new rings?

- If I remove the big end bearing caps to ensure there is no trapped grit, should I reuse them?

- If I remove the crank and the main bearings seem OK can I reuse them?

Hope this is helpful to other forumers!

gasket999

getting there...

- Messages

- 355

- Location

- Manchester, UK

Oh RTB, here's the inside of my motor case (see next post). Looks like the casing has broken (probably dropped on its side) and there was a captive terminal post in it. The wires to this terminal have been cut and I suspect that the chocolate blocks have been added as a replacement.

There is a melted wire which I'm holding with my stubby little fingers and also a small blob on a red wire.

Again, the case is full of paint so every bit will need to be cleaned. The wiring looks simple - haven't a clue what any of it does though, so I'll have to be systematic - there's plenty of slack in the main wire that runs to the pressure switch so I could strip it back and use fresh ends (assuming there's noting melted inside the main sheath) or I could replace the wiring in its entirety.

There is a melted wire which I'm holding with my stubby little fingers and also a small blob on a red wire.

Again, the case is full of paint so every bit will need to be cleaned. The wiring looks simple - haven't a clue what any of it does though, so I'll have to be systematic - there's plenty of slack in the main wire that runs to the pressure switch so I could strip it back and use fresh ends (assuming there's noting melted inside the main sheath) or I could replace the wiring in its entirety.

Wallace

Member

- Messages

- 7,705

- Location

- Staines, Middlesex, England.

I bet that would have been funny to watch when the paint hit home!  I wouldn't be surprised if you find there are no plain bearings in big ends and the crank runs directly on the rods. I think in the motor box there is a resettable trip missing that sits in the 1/2" hole at the end of the blue capacitor.

I wouldn't be surprised if you find there are no plain bearings in big ends and the crank runs directly on the rods. I think in the motor box there is a resettable trip missing that sits in the 1/2" hole at the end of the blue capacitor.

I wouldn't be surprised if you find there are no plain bearings in big ends and the crank runs directly on the rods. I think in the motor box there is a resettable trip missing that sits in the 1/2" hole at the end of the blue capacitor.

I wouldn't be surprised if you find there are no plain bearings in big ends and the crank runs directly on the rods. I think in the motor box there is a resettable trip missing that sits in the 1/2" hole at the end of the blue capacitor.gasket999

getting there...

- Messages

- 355

- Location

- Manchester, UK

Thanks Wallace - that would make sense - I wondered what that round hole was for! I really could do with some good photos if anyone has a SE16 from the same period (this one is post-april 2014)

Well I've sussed out a couple of things:

The mark on the bore and the jammed piston ring.

Turns out there was indeed a matching mark on the piston - on the upper edge directly above the first piston ring groove - it created the slightest burr in the groove which was nipping the piston ring.

I used the gap in the piston ring to access the burr and gently remove it.

So… just four more jobs to do before I can reassemble the pump with new (home-made) gaskets:

1) sort the mark on the bore - probably going to have to hone it with a glaze-buster. Hope this won't affect the piston ring gaps - what do you think?

2) polish the last of the burnt paint off the piston tops

3) decide how I'm going to clean out the crank case to ensure there's no grit in it. The best way would be to remove the big end caps, undo the main bearing end caps and remove the crank - this would give me the opportunity to inspect the big end and main bearings

4) degrease everything and clean the intake side of the head within an inch of its life - I'll take the valves off - they're only held on with two screws.

I'm not worried about the odd mark on the piston skirts - they're soft aluminium and, my understanding is that, the piston rings form the seal in the bore - not the pistons themselves.

On to the motor

1) I've whipped the two end caps off the motor - the paint hadn't penetrated past the bearing-dust shield at the pulley end and on the other end the fan needed cleaned but it had kept the paint away from the shaft.

2) I'm going to remove and repair the capacitor box (the box on top of the motor) - the base has completely cracked out of it, but it should plastic-weld back up.

3) Rewire the capacitors and motor supply - need to find someone with a similar capacitor set-up who can photograph this for me (mine is post-april 2014)

Well I've sussed out a couple of things:

The mark on the bore and the jammed piston ring.

Turns out there was indeed a matching mark on the piston - on the upper edge directly above the first piston ring groove - it created the slightest burr in the groove which was nipping the piston ring.

I used the gap in the piston ring to access the burr and gently remove it.

So… just four more jobs to do before I can reassemble the pump with new (home-made) gaskets:

1) sort the mark on the bore - probably going to have to hone it with a glaze-buster. Hope this won't affect the piston ring gaps - what do you think?

2) polish the last of the burnt paint off the piston tops

3) decide how I'm going to clean out the crank case to ensure there's no grit in it. The best way would be to remove the big end caps, undo the main bearing end caps and remove the crank - this would give me the opportunity to inspect the big end and main bearings

4) degrease everything and clean the intake side of the head within an inch of its life - I'll take the valves off - they're only held on with two screws.

I'm not worried about the odd mark on the piston skirts - they're soft aluminium and, my understanding is that, the piston rings form the seal in the bore - not the pistons themselves.

On to the motor

1) I've whipped the two end caps off the motor - the paint hadn't penetrated past the bearing-dust shield at the pulley end and on the other end the fan needed cleaned but it had kept the paint away from the shaft.

2) I'm going to remove and repair the capacitor box (the box on top of the motor) - the base has completely cracked out of it, but it should plastic-weld back up.

3) Rewire the capacitors and motor supply - need to find someone with a similar capacitor set-up who can photograph this for me (mine is post-april 2014)

gasket999

getting there...

- Messages

- 355

- Location

- Manchester, UK

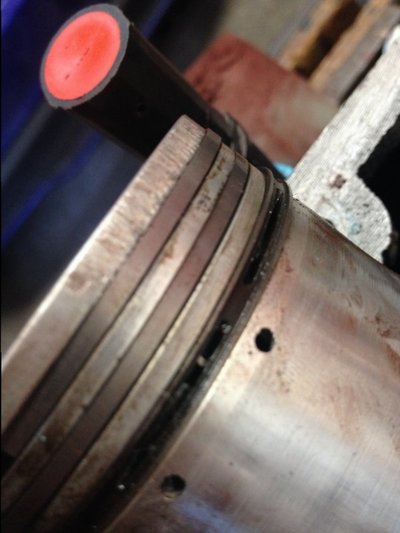

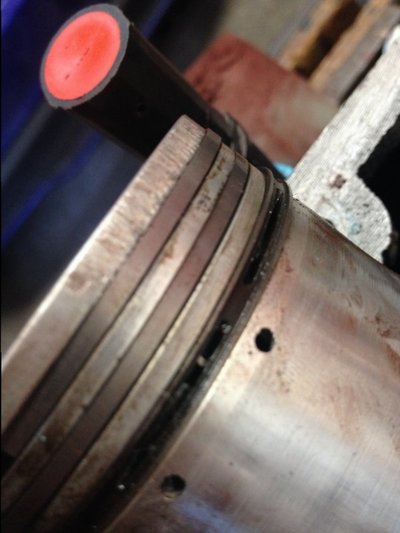

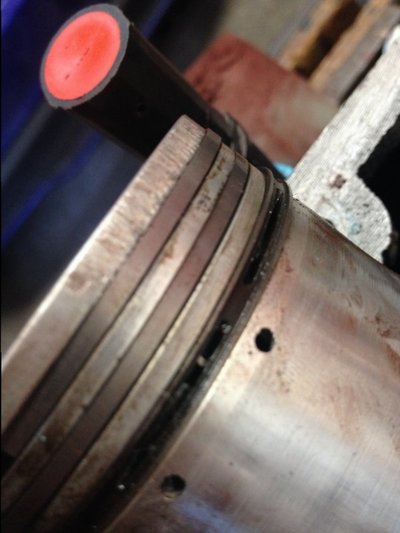

Here's the mark on the bore and the corresponding piston mark.

What do you reckon:

1) Ignore it

2) ignore the damage on the soft aluminium piston but correct the damage to the bore?

2a) if fixing the bore should I do it by hand with a light wet and dry paper…

2b) or use a glaze-buster (I think this would reduce the damage without affecting the piston ring clearance.

2c) if it needs a proper rebore then I'd be better buying a new pump, which would write-off the project.

What do you reckon:

1) Ignore it

2) ignore the damage on the soft aluminium piston but correct the damage to the bore?

2a) if fixing the bore should I do it by hand with a light wet and dry paper…

2b) or use a glaze-buster (I think this would reduce the damage without affecting the piston ring clearance.

2c) if it needs a proper rebore then I'd be better buying a new pump, which would write-off the project.

roofman

Purveyor of fine English buckets and mops

- Messages

- 12,166

- Location

- North West with water on 3 sides

ide just lightly hone the bores...no more than half a dozen passes with an expanding 3 stone and plenty of WD40,lubes but allows the stones to cut.....run the pick-up marks on the pistons with a fine Emery and as rtb has said make sure the rings are free and can expand.

A good way of cleaning crud from an alloy piston is to use a 2p as a scraper. I'm sure you know to place the ring gaps 120 degrees apart when refitting.

A popular replacement for the air filter on a compressor is a car oil filter. Some of them have a 1/2" bsp thread and will fit straight onto your head using a suitable bsp nipple adaptor.

Personally I would strip the crankcase and give the bottom end a good cleaning, especially given the obvious lack of maintenance or care by the previous owner. 2 stroke petrol mixture is ideal for this as the petrol will do the cleaning and when it evaporates it leaves the oil behind as a protective layer. The big end is likely a plain bearing, lube it with compressor oil when rebuilding.

A popular replacement for the air filter on a compressor is a car oil filter. Some of them have a 1/2" bsp thread and will fit straight onto your head using a suitable bsp nipple adaptor.

Personally I would strip the crankcase and give the bottom end a good cleaning, especially given the obvious lack of maintenance or care by the previous owner. 2 stroke petrol mixture is ideal for this as the petrol will do the cleaning and when it evaporates it leaves the oil behind as a protective layer. The big end is likely a plain bearing, lube it with compressor oil when rebuilding.