You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CNC Plasma build

- Thread starter MattH

- Start date

MattH

Member

- Messages

- 4,522

- Location

- Cornwall

Right, started digging into this bevel issue. Up to now i've only been cutting 2mm so it's been hard to tell.

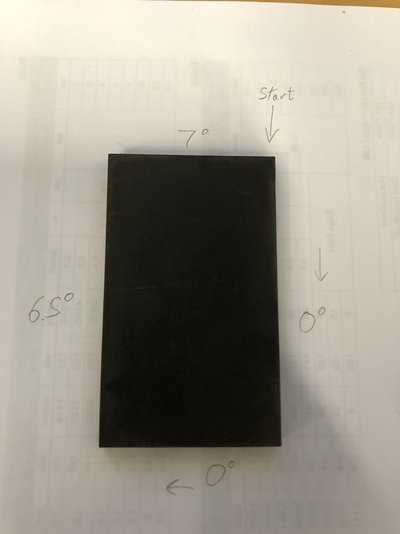

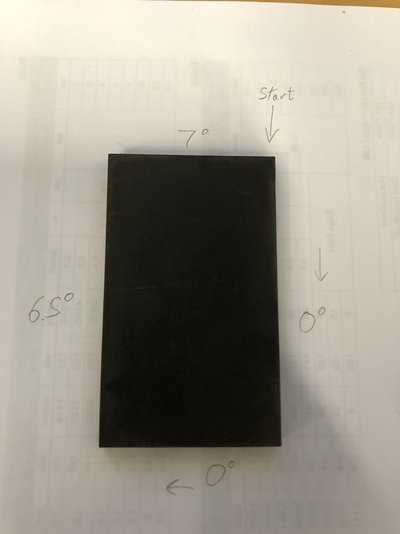

I cut another 6mm coupon and broke out my Starrett protractor:

First two sides are bang on right angles, the next two are somewhere between 6.5-7 degs bevel.

So it looks like it might be a torch alignment issue. I will keep digging.

I cut another 6mm coupon and broke out my Starrett protractor:

First two sides are bang on right angles, the next two are somewhere between 6.5-7 degs bevel.

So it looks like it might be a torch alignment issue. I will keep digging.

MattH

Member

- Messages

- 4,522

- Location

- Cornwall

Struggling to wrap my head around this.

Checked torch for alignment which is fine.

Slowed feed right down still the same.

Tried direct earthing of the stock, still the same.

Tried different consumables (Thermacut rather than HT), still the same.

I've seen mention by Jim Holt (HT guy) that the Oring on the torch can cause these issues but I don't have a spare to test with.

Checked torch for alignment which is fine.

Slowed feed right down still the same.

Tried direct earthing of the stock, still the same.

Tried different consumables (Thermacut rather than HT), still the same.

I've seen mention by Jim Holt (HT guy) that the Oring on the torch can cause these issues but I don't have a spare to test with.

chrisg3103

Forum Supporter

- Messages

- 785

Is this maybe something to do with swirl direction? Try cutting counter clockwise and see if it changes?

MattH

Member

- Messages

- 4,522

- Location

- Cornwall

Is this maybe something to do with swirl direction? Try cutting counter clockwise and see if it changes?

No, the correct direction for the consumables is clockwise on an outside cut (best angle on right of cut in relation to direction of travel).

I had actually tried it because sheetcam was setup to cut CCW until I changed it.

mtt.tr

Member

- Messages

- 8,431

- Location

- Essex/Suffolk border

Struggling to wrap my head around this.

Checked torch for alignment which is fine.

Slowed feed right down still the same.

Tried direct earthing of the stock, still the same.

Tried different consumables (Thermacut rather than HT), still the same.

I've seen mention by Jim Holt (HT guy) that the Oring on the torch can cause these issues but I don't have a spare to test with.

is it being pulled out of alignment or pivoting when the direction changes

MattH

Member

- Messages

- 4,522

- Location

- Cornwall

I just rotated the torch by 90degs in the holder.

The results are:

Before: 0,0,6.5,7

After: 3,0,6,4

Seems like it's possibly something with the torch.

I'm going to loosen the torch lead which is cable tied to a number of things at the moment and retry.

The results are:

Before: 0,0,6.5,7

After: 3,0,6,4

Seems like it's possibly something with the torch.

I'm going to loosen the torch lead which is cable tied to a number of things at the moment and retry.

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,993

- Location

- East Yorkshire

Is this maybe something to do with swirl direction? Try cutting counter clockwise and see if it changes?

No, the correct direction for the consumables is clockwise on an outside cut (best angle on right of cut in relation to direction of travel).

I had actually tried it because sheetcam was setup to cut CCW until I changed it.

Is the rotation always the same direction? (You know where Im going with this

. seriously though)

. seriously though)MattH

Member

- Messages

- 4,522

- Location

- Cornwall

I unclipped the torch lead and loosen the torch clamp to allow to torch to find it's neutral rotation which was about 45degs from where it was.

This has again changed the bevels:

Before: 0, 0, 6.5, 7

After: 3, 0, 6, 4

Now: 4.5, 1, 3.5, 4.5

Seems any twist in the lead is being seen at the arc.

This has again changed the bevels:

Before: 0, 0, 6.5, 7

After: 3, 0, 6, 4

Now: 4.5, 1, 3.5, 4.5

Seems any twist in the lead is being seen at the arc.

MattH

Member

- Messages

- 4,522

- Location

- Cornwall

Is the rotation always the same direction? (You know where Im going with this. seriously though)

Not following.

Is the direction of cut always the same? Yes, it's now always CW.

The swirl ring only fits one way so the best cut is always CW outside ccw inside.

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 17,993

- Location

- East Yorkshire

Not following.

Is the direction of cut always the same? Yes, it's now always CW.

The swirl ring only fits one way so the best cut is always CW outside ccw inside.

sorry I thought you were referring to the plasma arc having a Swirl, a bit like water swirls down the plughole. That favoured one direction of cut

MattH

Member

- Messages

- 4,522

- Location

- Cornwall

Is it a genuine Hypertherm machine torch?

yes it is. I tested with genuine HT consumables and with Thermacut consumables with the same results.

MattH

Member

- Messages

- 4,522

- Location

- Cornwall

I found a thread on another forum where someone had been having the same issue. After exhausting all options someone from HT told them to check the torch O ring which he replaced and this fixed the issue.

I’ve checked the O ring which seems ok but is completely dry. I have ordered some silicone grease.

I’ve checked the O ring which seems ok but is completely dry. I have ordered some silicone grease.

Hood

I am obsessed.

- Messages

- 17,306

- Location

- Carnoustie, Scotland

Lots of things can cause the bevel but it does seem to be torch related in your case. It could well be the 'O' Ring as I had similar with my Trafimet torch a while back. The 'O' Ring on mine however was visibly damaged so was easily seen.

@MattH speak to @doubleboost as his sponsor sells tables and machines.I found a thread on another forum where someone had been having the same issue. After exhausting all options someone from HT told them to check the torch O ring which he replaced and this fixed the issue.

I’ve checked the O ring which seems ok but is completely dry. I have ordered some silicone grease.

He might have O rings and or advice.

MattH

Member

- Messages

- 4,522

- Location

- Cornwall

@MattH speak to @doubleboost as his sponsor sells tables and machines.

He might have O rings and or advice.

John’s stuff is all RTech.

I’m running a Hypertherm which is American made and all proprietary.

I have an O ring kit so I’ll try to match one up but I’ll also lube the one that’s in there.

https://www.plasmaspider.com/viewtopic.php?f=4&t=22068

This thread has 3 pages of various people fixing the exact same issue with an O ring so fingers crossed.

Hood

I am obsessed.

- Messages

- 17,306

- Location

- Carnoustie, Scotland

These people do most 'O' Ring sizes and are very quick on delivery.

https://www.ebay.co.uk/itm/36293226...il=sys&xt=Ctrl_EmailConfirmation_FooterUpdate

https://www.ebay.co.uk/itm/36293226...il=sys&xt=Ctrl_EmailConfirmation_FooterUpdate

I thought Robert moved away from R-tech and added options. 1 of which was hyper therm.John’s stuff is all RTech.

I’m running a Hypertherm which is American made and all proprietary.

I have an O ring kit so I’ll try to match one up but I’ll also lube the one that’s in there.

https://www.plasmaspider.com/viewtopic.php?f=4&t=22068

This thread has 3 pages of various people fixing the exact same issue with an O ring so fingers crossed.

But I just checked his website and its almost all R-tech machines now.

I could swear I saw hypertherm and swiftcut on there a while back.

Hood

I am obsessed.

- Messages

- 17,306

- Location

- Carnoustie, Scotland

I think he does supply Hypertherm if the customer asks for it.I thought Robert moved away from R-tech and added options. 1 of which was hyper therm.

But I just checked his website and its almost all R-tech machines now.

I could swear I saw hypertherm and swiftcut on there a while back.