- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dividing Head for a Tom Senior Light Vertical

- Thread starter Rannsachair

- Start date

Rannsachair

Forum Supporter

- Messages

- 4,105

- Location

- Lochgilphead, Argyll, Republic of Scotland

Dictionary“Swithering”?

Definitions from Oxford Languages ·

swither

/ˈswɪðə/

SCOTTISH

verb

gerund or present participle: swithering

- be uncertain as to which course of action to choose.

Just keep your eye on Ebay - bargains do turn up sometimes.

I picked up my 6" Cincinnati in good condition for £90. The badge was missing - didn't know it was a Cincinnati until after I had bought it.

Thing is huge though.

Smaller ones go for better money but you can still get an Elliott or similar for less than £200.

Often without tail stocks but any universal one will do if the centre height is the same.

I picked up my 6" Cincinnati in good condition for £90. The badge was missing - didn't know it was a Cincinnati until after I had bought it.

Thing is huge though.

Smaller ones go for better money but you can still get an Elliott or similar for less than £200.

Often without tail stocks but any universal one will do if the centre height is the same.

DIVIDING HEAD 4 1/2IN ENGINEERS TOOLING MILLING MACHINE MILLING CUTTERS END MILL

DIVIDING HEAD 4 1/2IN ENGINEERS TOOLING MILLING MACHINE MILLING CUTTERS END MILL in Business, Office & Industrial, CNC, Metalworking & Manufacturing, Metalworking Equipment, Machining Centers & Milling Machines | eBay

www.ebay.co.uk

This looks pretty good. Says buyer to collect but usually ways around that. We could ship it for you as a small crate rather than a pallet if he or someone on the forum can help you out.

citizen kane

Member

- Messages

- 260

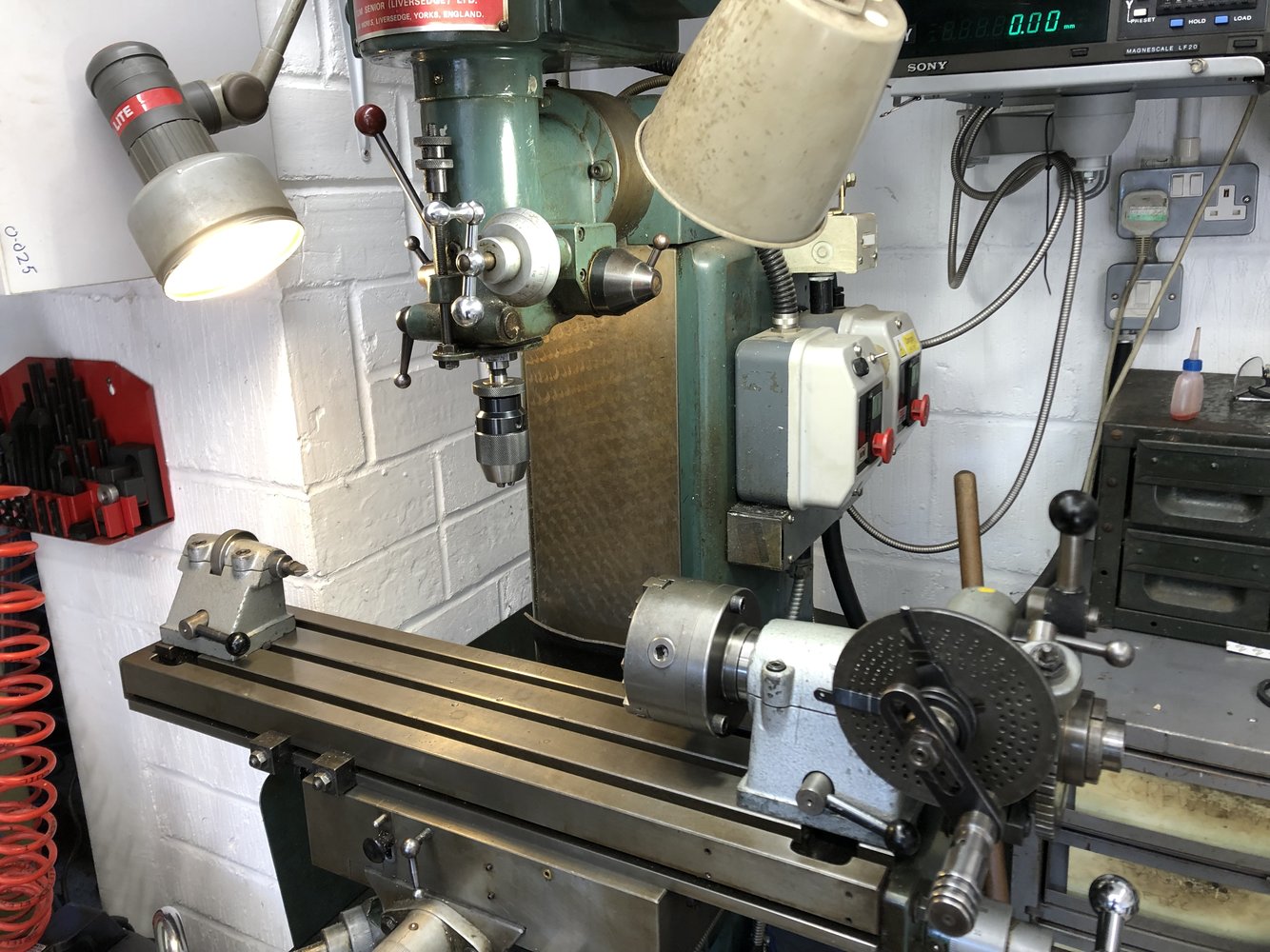

These are a few pics of dividing heads on a Tom Senior,

Both are nominally the same size with 4" chucks, the Hofmann has the advantage of a higher center height so I can bolt of a 6" chuck, the Aciera has the advantage of being able to accommodate collets in the spindle, both are a good size for the Tom Senior.

Both are nominally the same size with 4" chucks, the Hofmann has the advantage of a higher center height so I can bolt of a 6" chuck, the Aciera has the advantage of being able to accommodate collets in the spindle, both are a good size for the Tom Senior.

not done it yet

Member

- Messages

- 2,630

- Location

- Lincs/cambs/Rutland/Northants

Managed this with it so it wasn't all bad.

What is the run-out on the chuck? I would be using a 4 jaw independent chuck for gear cutting.

My recent purchase of a chinese diesel heater was not to their specifications, but works well enough - no dip-tube for taking fuel from the top of the tank, the thermostat is way off (set the temp for 5 Celsius and no regulation until about 12-14 registers on the controller), the minimum fuel delivery is nearly 50% more than specified and (of course) it is nowhere near delivering 5kW at full output.

I could have sent it back, I suppose, but it is (just about) good enough for what I need it for. But there are thousands out there that are blissfully unaware of the ‘out-of-spec’ items they have bought.

Where I used to buy beekeeping equipment the products were first quality - no knotty timber used, and the knotty bits were sold off as seconds in their annual sales. Some of this chinese stuff is simply rejected castings, etc that have been reworked or sold (with the machining defects), as good items. I expect that most of the stuff is out of specification on one point or another - or is built with rejected castings.

What I say, about engineering stuff, is don’t buy unless you can afford to throw it away. I am able to fettle a lot of things, but a MT2 arbor that is not MT2 (loose in a socket) is of no use whatsoever - at any price reduction offered!

I've no idea about the run out on the chuck. I should check and find out. It was fine for my purposes. Gears for a set of slip rolls, so precision was not required.

I could swap the 3 jaw out for a four jaw on my Southbend I think. The thread is the same. I would have to check the register but they are likely to be the same too.

I could swap the 3 jaw out for a four jaw on my Southbend I think. The thread is the same. I would have to check the register but they are likely to be the same too.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,382

- Location

- NE London - UK

I would be using a 4 jaw independent chuck for gear cutting.

I used a collet chuck.

Rannsachair

Forum Supporter

- Messages

- 4,105

- Location

- Lochgilphead, Argyll, Republic of Scotland

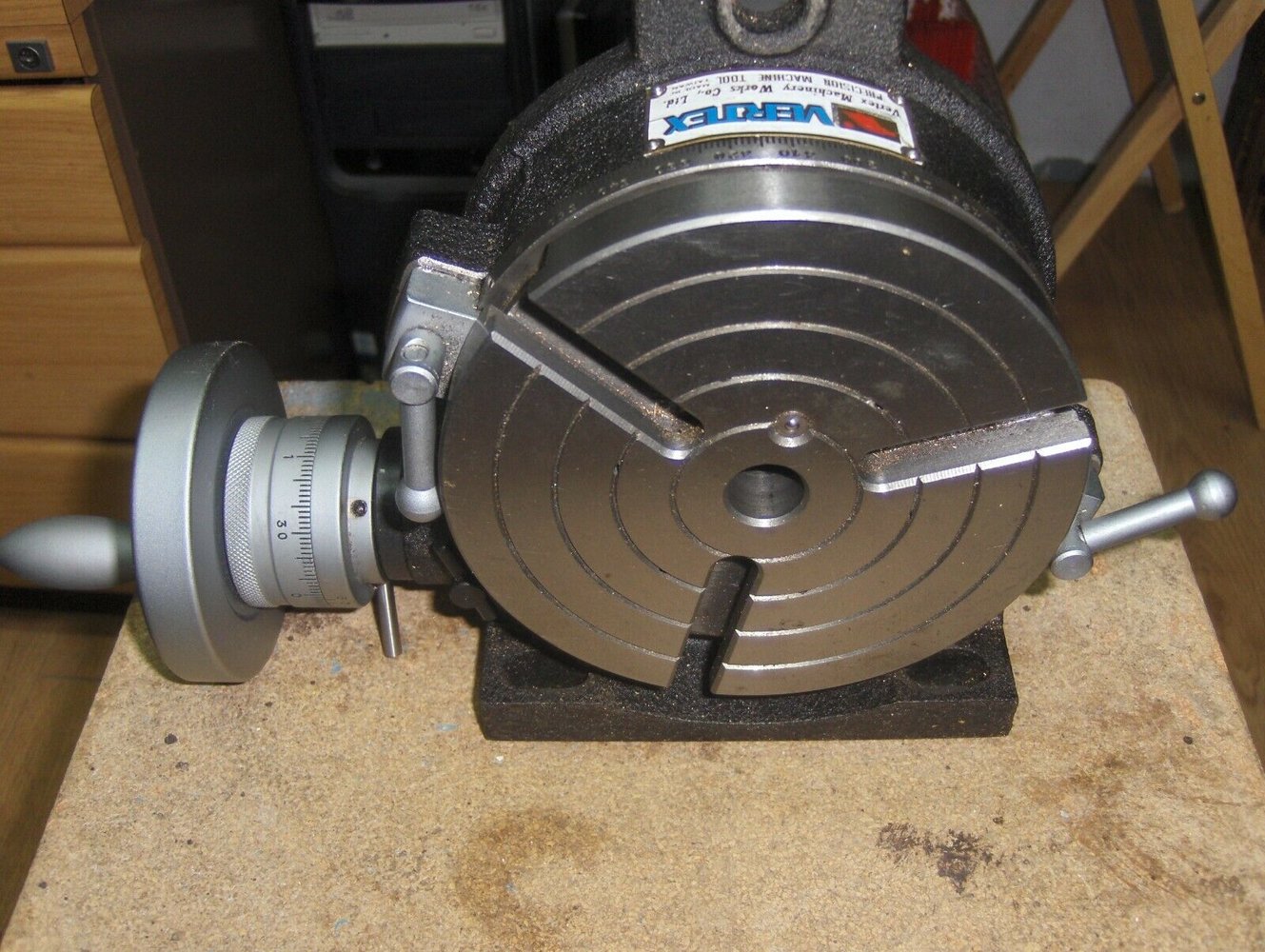

Ended up winning what looks a good Vertex HV-6 of ebay, not arrived yet, just need to buy a chuck to suit.

I think a 125mm (5") chuck will suit.

I think a 125mm (5") chuck will suit.

Agroshield

Member

- Messages

- 5,695

It looks like the division tables have been prepared by the previous owner. I believe the ones in the official manual contain some errors so at the very least put a post it note inside the manual to alert you to this possibility.

If you want to post legible pictures of the tables, we can review them and then you can obliterate any errors before you are caught out.

One thing to check on the table is whether the T-slots line up with a whole number on the degree scale (i.e. degrees reading zero, T-slot either north-south or east-west). Mine did not and I had to make a new brass zero-indicator to correct.

Before you buy a chuck, consider the method of attachment to the table - front-mountable three jaws are difficult because of the scroll. A 5" chuck on a 6" table only gives you 1/2" around the perimeter for a toe or pin clamp, so 4" might be better in that respect. If you use a sub-plate, the larger the PCD of the holes in the back of the chuck (to attach it to the sub-plate), the more difficult it becomes to find space to attach the sub-plate to the table.

A 2 MT to parallel shaft (e.g. 2MT test bar) is helpful to align the chuck concentric with the table.

If you want to post legible pictures of the tables, we can review them and then you can obliterate any errors before you are caught out.

One thing to check on the table is whether the T-slots line up with a whole number on the degree scale (i.e. degrees reading zero, T-slot either north-south or east-west). Mine did not and I had to make a new brass zero-indicator to correct.

Before you buy a chuck, consider the method of attachment to the table - front-mountable three jaws are difficult because of the scroll. A 5" chuck on a 6" table only gives you 1/2" around the perimeter for a toe or pin clamp, so 4" might be better in that respect. If you use a sub-plate, the larger the PCD of the holes in the back of the chuck (to attach it to the sub-plate), the more difficult it becomes to find space to attach the sub-plate to the table.

A 2 MT to parallel shaft (e.g. 2MT test bar) is helpful to align the chuck concentric with the table.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,382

- Location

- NE London - UK

A nice table, and compete too. I have the same setup and it's worked well for me. I used a 2MT to Boxford adaptor, but you do lose about 3/4" height that way.

The wavy washer for the sector arms didn't work very well for me. I came up with a completely over- designed remedy for that

I stripped and cleaned it as well. There was, I seem to recall, some traces of casting sand inside. Mine wasn't new, but had sat in someone's shed for a few years with minimal or no work. Also played around with an O arrangement to seal the shaft.

The wavy washer for the sector arms didn't work very well for me. I came up with a completely over- designed remedy for that

I stripped and cleaned it as well. There was, I seem to recall, some traces of casting sand inside. Mine wasn't new, but had sat in someone's shed for a few years with minimal or no work. Also played around with an O arrangement to seal the shaft.

Rannsachair

Forum Supporter

- Messages

- 4,105

- Location

- Lochgilphead, Argyll, Republic of Scotland

Thanks for that Graham, I suspect I will do similar.A nice table, and compete too. I have the same setup and it's worked well for me. I used a 2MT to Boxford adaptor, but you do lose about 3/4" height that way.

The wavy washer for the sector arms didn't work very well for me. I came up with a completely over- designed remedy for that

View attachment 339024View attachment 339025View attachment 339026

I stripped and cleaned it as well. There was, I seem to recall, some traces of casting sand inside. Mine wasn't new, but had sat in someone's shed for a few years with minimal or no work. Also played around with an O arrangement to seal the shaft.

not done it yet

Member

- Messages

- 2,630

- Location

- Lincs/cambs/Rutland/Northants

It will likely be better if the tag indicates made in Taiwan rather than China. They are the older ones.

Both mine were made in Taiwan, one with three T-slots and the other with four.

I still don’t use mine for heavy circular milling duties - they are not as robust as some much older European variants - so I do most machining by plunge cuts whenever possible.

Do not trust the table of settings. Some contained the odd fault - and it would likely be something important when you eventually find out! I calculate all my increments - it is a mathematical doddle, once you realise how easy it is.

I have fitted one of mine to a base plate because they don‘t fit my table slot-spacing.

Both mine were made in Taiwan, one with three T-slots and the other with four.

I still don’t use mine for heavy circular milling duties - they are not as robust as some much older European variants - so I do most machining by plunge cuts whenever possible.

Do not trust the table of settings. Some contained the odd fault - and it would likely be something important when you eventually find out! I calculate all my increments - it is a mathematical doddle, once you realise how easy it is.

I have fitted one of mine to a base plate because they don‘t fit my table slot-spacing.

Rannsachair

Forum Supporter

- Messages

- 4,105

- Location

- Lochgilphead, Argyll, Republic of Scotland

It is labelled made in Taiwan, so I may be lucky.It will likely be better if the tag indicates made in Taiwan rather than China. They are the older ones.

Both mine were made in Taiwan, one with three T-slots and the other with four.

I still don’t use mine for heavy circular milling duties - they are not as robust as some much older European variants - so I do most machining by plunge cuts whenever possible.

Do not trust the table of settings. Some contained the odd fault - and it would likely be something important when you eventually find out! I calculate all my increments - it is a mathematical doddle, once you realise how easy it is.

I have fitted one of mine to a base plate because they don‘t fit my table slot-spacing.

RobCox

Member

- Messages

- 449

- Location

- Cambridge, UK

I think a 125mm (5") chuck will suit.

I've got a 6 inch Vertex too and put a 5inch chuck on it. Can be done, but it's tight. I'll take a pic later of what I did.

3 jaw - Just put a front mounting chuck on, eg:

4 jaw will need a plate making most likely.

4 jaw will need a plate making most likely.

Rannsachair

Forum Supporter

- Messages

- 4,105

- Location

- Lochgilphead, Argyll, Republic of Scotland

Funny, I was looking at http://www.rotagriponline.com/index...tegory_id=235&option=com_virtuemart&Itemid=293 jaw - Just put a front mounting chuck on, eg:

4 jaw will need a plate making most likely.

RobCox

Member

- Messages

- 449

- Location

- Cambridge, UK

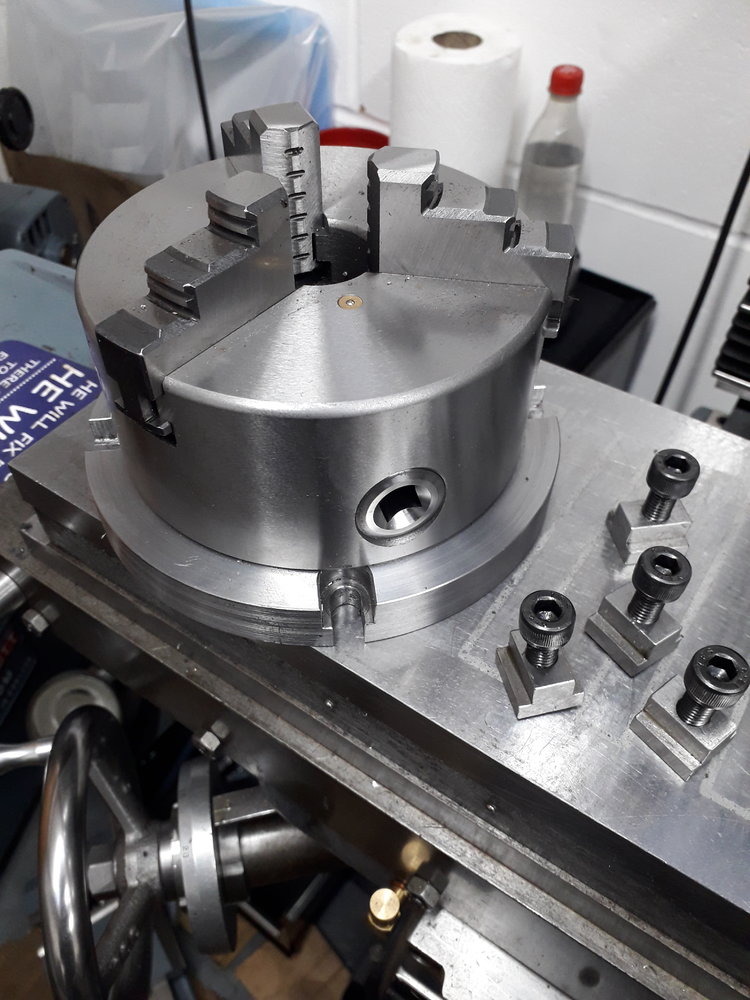

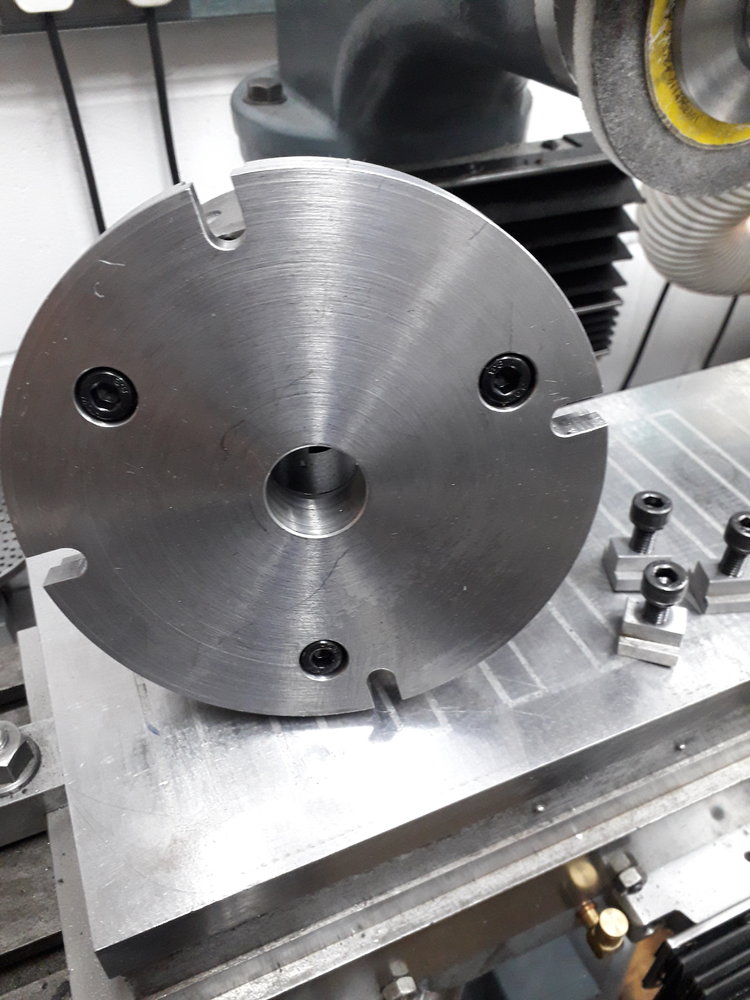

That 5" front mounting 3 jaw from rotagrip would have been too spendy for me. I settled for a rear mounting one from Arceurotrade, less than £50, prob not as accurate, but for holding and rotating items on the shaper for cutting internal splines, good enough for me. This is the chuck and the backplate that fits on my 6" vertex rotab:

The hole in the centre of the backing plate fits a pin that is a snug fit in the rotab centre hole, makes lining it up quicker if precision isn't needed.

The hole in the centre of the backing plate fits a pin that is a snug fit in the rotab centre hole, makes lining it up quicker if precision isn't needed.