You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Review EWM 8m PC2 Push-Pull

- Thread starter Hood

- Start date

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

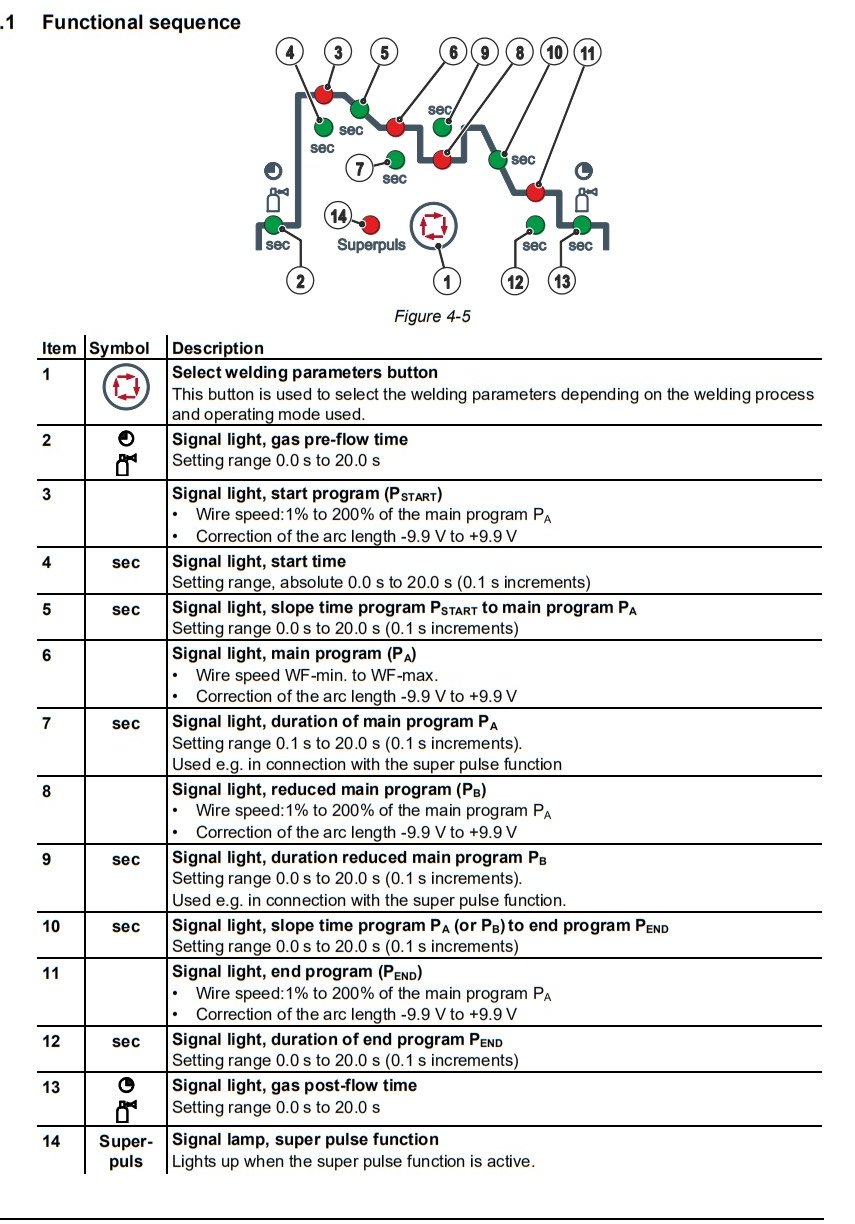

Here is what you can adjust for each programme. note when in special 4t mode the times at numbers 4 and 12 are controlled by you with the trigger rather than using the times stored. That makes it much better for varied work as you can yourself decide how long it needs the hot start and same again for crater fill.

And as mentioned before, the currents for start, low and end are a % of the main current so if you alter the main current the others automatically adjust.

And as mentioned before, the currents for start, low and end are a % of the main current so if you alter the main current the others automatically adjust.

hotponyshoes

Member

- Messages

- 7,801

- Location

- Somerset. Uk

You should get paid to be a brand ambassador for EWM.

Can't you contact ewm and get them to send him a 'test' version of the pc software..

He would make a good test bed for a single-use version..

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

You know my account detailsYou should get paid to be a brand ambassador for EWM.

hotponyshoes

Member

- Messages

- 7,801

- Location

- Somerset. Uk

Can you change program during a weld run?

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Can you change program during a weld run?

Do you mean whilst welding? If so then I wouldn't think so but will give it a try in a bit.

hotponyshoes

Member

- Messages

- 7,801

- Location

- Somerset. Uk

Cool. So if you set enough programs you can just skip through them as if you were adjusting wire feed speed. Just need the software to set it all up.

@Jim maybe you should get the software and add it to the hire fleet

Remote air shutter release .

First one I found, £14 for 6m.

You could mount the bulb on the python behind you out the way of the gun.

3d printed bracket, fit to the welder with double-sided velcro tape. It will push the switch for you. No warranty broken.

@Jim maybe you should get the software and add it to the hire fleet

Remote air shutter release .

First one I found, £14 for 6m.

You could mount the bulb on the python behind you out the way of the gun.

3d printed bracket, fit to the welder with double-sided velcro tape. It will push the switch for you. No warranty broken.

hotponyshoes

Member

- Messages

- 7,801

- Location

- Somerset. Uk

Actually you can

Does give you a few options:

Ie. For welding 8mm,

Job #180 = 8mm. No pulse

Program #8 = your default settings for that

Programs 7, 6 , 5... lower wire speeds in steps of 1

Programs 9, 10, 11.... higher wire speeds in step of 1

Job #181 = 8mm single pulse

Programs same as before

Job #182 = 8mm double pulse

Programs same as before

You could then go as far as Job# 280/281/281 is also 8mm but the programs all change the wire speed in steps of 2. (Or 5 or whatever)

Job 380 could change something different.

I dont know how many memory allocations are available and aside from the machine you would also be limited to how many you could remember yourself!

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Cool. So if you set enough programs you can just skip through them as if you were adjusting wire feed speed. Just need the software to set it all up.

@Jim maybe you should get the software and add it to the hire fleet

You would have to switch jobs as well as 15 programmes wouldn't be enough. On the test I have just done I have set up from 1mm to 8mm in 0.5mm increments.

Hope the bulb is hot spatter proofView attachment 260954

Remote air shutter release .

First one I found, £14 for 6m.

You could mount the bulb on the python behind you out the way of the gun.

3d printed bracket, fit to the welder with double-sided velcro tape. It will push the switch for you. No warranty broken.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Does give you a few options:

Ie. For welding 8mm,

Job #180 = 8mm. No pulse

Program #8 = your default settings for that

Programs 7, 6 , 5... lower wire speeds in steps of 1

Programs 9, 10, 11.... higher wire speeds in step of 1

Job #181 = 8mm single pulse

Programs same as before

Job #182 = 8mm double pulse

Programs same as before

You could then go as far as Job# 280/281/281 is also 8mm but the programs all change the wire speed in steps of 2. (Or 5 or whatever)

Job 380 could change something different.

I dont know how many memory allocations are available and aside from the machine you would also be limited to how many you could remember yourself!

Jobs are 129 - 169. I don't think you can set up programmes in default Jobs but anyway I will give things a try out and see.

hotponyshoes

Member

- Messages

- 7,801

- Location

- Somerset. Uk

If 1mm to 9mm pretty much covers you then you can do it that way,

Job 101 basic 1mm, programs change wire speed

Job 110 single pulse, 1mm

Job 210 twin pulse 1mm

Job 310 basic 1mm, programs change something else..

Job 102 basic 2mm, rinsed & repeated

There is a "specialised" leather sheath product that a bulb like that would fit into. I am not prepared to do a search for it.

Job 101 basic 1mm, programs change wire speed

Job 110 single pulse, 1mm

Job 210 twin pulse 1mm

Job 310 basic 1mm, programs change something else..

Job 102 basic 2mm, rinsed & repeated

There is a "specialised" leather sheath product that a bulb like that would fit into. I am not prepared to do a search for it.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

If 1mm to 9mm pretty much covers you then you can do it that way,

Job 101 basic 1mm, programs change wire speed

Job 110 single pulse, 1mm

Job 210 twin pulse 1mm

Job 310 basic 1mm, programs change something else..

Job 102 basic 2mm, rinsed & repeated

I go more than 9mm on occasions and very rarely under 3mm but being able to drop down to 1.5-2mm can help with different positional welds.

Regarding jobs I only ever use pulse or super pulse and although I have a few different SuperPulse Jobs set up I tend to just use one of them. Would be a weeks work setting them up though

CowardThere is a "specialised" leather sheath product that a bulb like that would fit into. I am not prepared to do a search for it.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

Got the bouncing wire feed issue again

Took off the neck and the teflon liner in the neck was clear but I noticed down in the feed tube there was this.

Obviously something not right when the wire is getting shaved like that

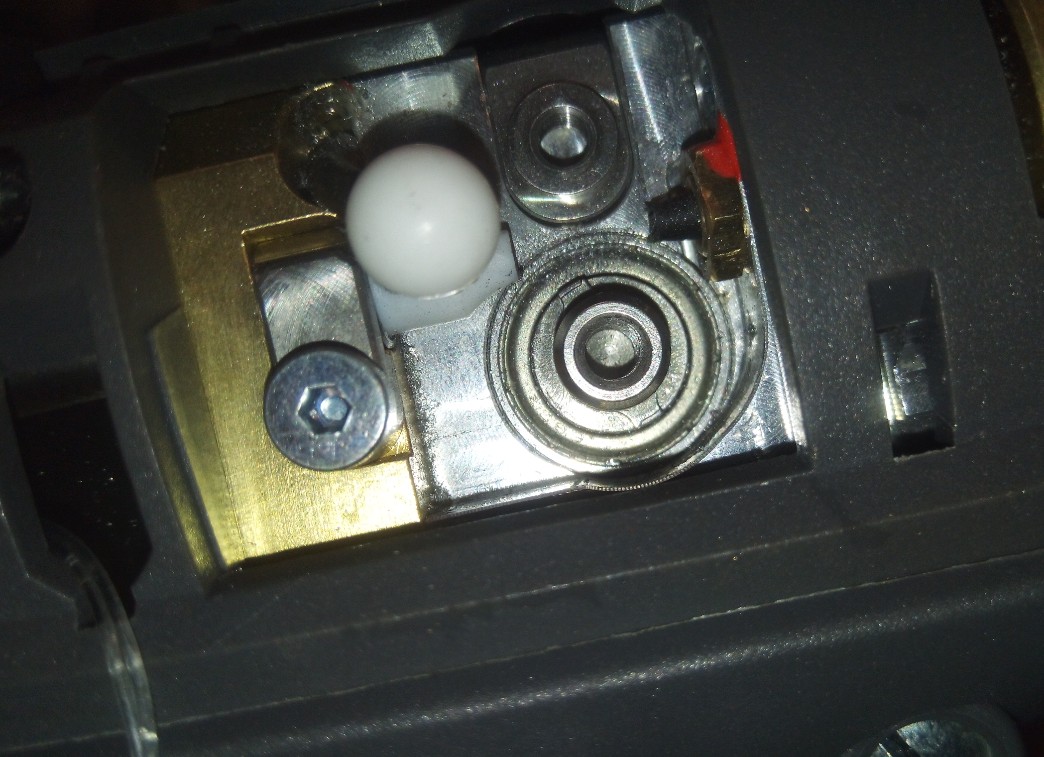

Had a look in at the wire feed rollers and as you can see the lower one (top one has been removed) is not in alignment with the feed tubes yet it seems to be seated on the dogs.

I removed it and cleaned it out and this time it went onto the dog then a further wee push and it snapped into place.

Pic of the dogs

Pic of the roller.

I can only assume that it had been sitting on the slight internal step but as can be seen now it is fully seated and aligned so some one needs a slap

Tested out and back to silky smooth wire feed again and I am confident that is the end of that issue

I then put the pistol grip on to see what that felt like and it is nice, better grip than the round handle of the binzel and the trigger is nice and smooth with positive action.

Only two screws need removed and the pistol grip clicks in place and you put in smaller Dia but longer screws to secure it properly, so only takes a minute or less to put it on or take off. One thing that I will likely do however is drill and tap a couple of holes on the bottom of the pistol grip to hold the original screws so that I don't loose them should I remove the pistol grip.

Took off the neck and the teflon liner in the neck was clear but I noticed down in the feed tube there was this.

Obviously something not right when the wire is getting shaved like that

Had a look in at the wire feed rollers and as you can see the lower one (top one has been removed) is not in alignment with the feed tubes yet it seems to be seated on the dogs.

I removed it and cleaned it out and this time it went onto the dog then a further wee push and it snapped into place.

Pic of the dogs

Pic of the roller.

I can only assume that it had been sitting on the slight internal step but as can be seen now it is fully seated and aligned so some one needs a slap

Tested out and back to silky smooth wire feed again and I am confident that is the end of that issue

I then put the pistol grip on to see what that felt like and it is nice, better grip than the round handle of the binzel and the trigger is nice and smooth with positive action.

Only two screws need removed and the pistol grip clicks in place and you put in smaller Dia but longer screws to secure it properly, so only takes a minute or less to put it on or take off. One thing that I will likely do however is drill and tap a couple of holes on the bottom of the pistol grip to hold the original screws so that I don't loose them should I remove the pistol grip.

Hood

Member

- Messages

- 17,542

- Location

- Carnoustie, Scotland

I will have to see if Santa will get me one, spent too much at the momentWould you like a price on the 45 degree neck?

Jim Davey

R H Davey Welding Supplies Ltd

- Messages

- 5,653

- Location

- Southampton

You know my account details

i wasn’t offering to employ you.