You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gertie the 73 VW T2 bay window

- Thread starter Exuptoy

- Start date

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

Today's work was to reassemble the hub with new bearings and brake assy which went without issue and my new Boge dampers arrived so a new one was fitted at the same time.

I cleaned all the floor (half) back to clean shiny metal before covering it with Rusto, still have minor floor repairs to carry out and a half load floor to purchase but it's still going forward.

I cleaned all the floor (half) back to clean shiny metal before covering it with Rusto, still have minor floor repairs to carry out and a half load floor to purchase but it's still going forward.

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

Yeah, that's great, but I want to go through it all and make sure its the best I can do and hopefully it will be safe and legal without having to worry about a looming test. I still think exempt vehicles should have a test say once in 5 years as there are some unscrupulous vendors out there and not all owners are handy when it comes to maintenance.

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

Things like outer sills, rear arches and load floor etc will be done when it's back on its wheels so for the next few weeks I think I will concentrate on painting and overhauling front brakes and suspension components so when it finally sits on its wheels I can get stuck into bits which really will put the finish line in view. Soon it'll start to feel like a bus again.

jpmillermatic

Member

- Messages

- 1,094

yes, that paint on the floor really looks great...it certainly brings attention to how nice the frame rails look too!

JP

JP

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

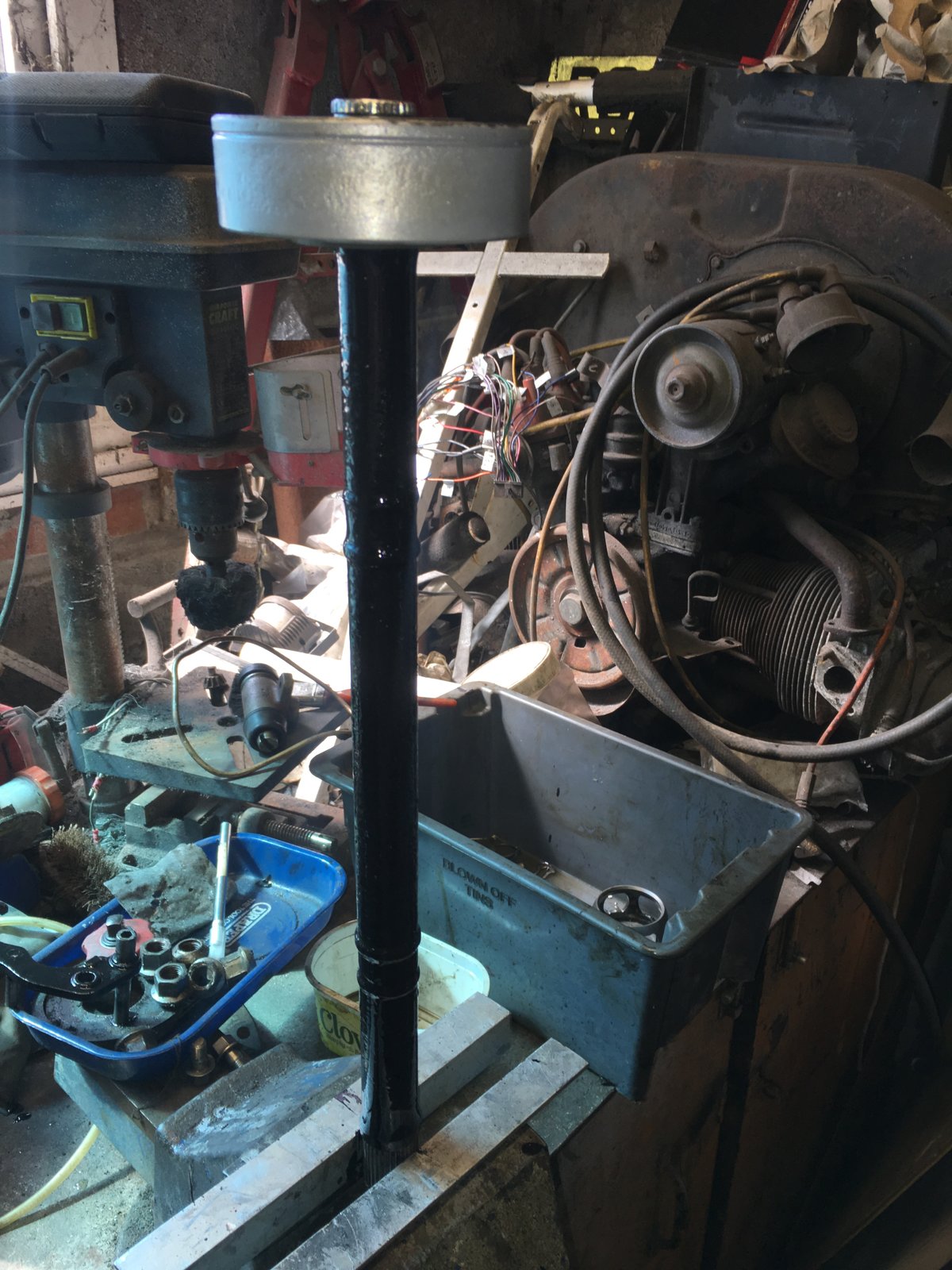

Fish'd my drive shaft out of the de-rusting bucket and stuck a coat of Kurust on it then some black Rusto. Also sprayed the CV joint silver. Tried getting my handbrake cable pipe fitted which entailed drilling the jacking point and the chassis a little but the pipe was 12.5mm OD so was very tight but it was a pig to fit as it was too stiff to bend to shape. Wrote it off as a bad job so need to find thinner walled pipe. Called it a day and went out on the 675 to buy some top coat and lacquer for the 955i lower fairing repair.

Last edited:

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

After previously struggling to shape the handbrake conduit in little increments I had a bit of a brainwave and I used my conduit bender and pre shaped the rear end where it travelled through the main chassis rails then tapped it rearwards until it was past where I needed then knocked it back forwards and popped it through the crossmember before threading in the cable.

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

Today I decided to get the other handbrake tube in. Some struggling and choice words saw it finished. I notice there was a cable with a wing nut on it wrapped around the front beam which turned out to be the clutch cable and I also found another large tube I didn't know was in the garage so I proceeded to install the clutch cable and Bowden tube. A good coat of etch primer then saw me paint all three tubes with grey Rusto and I have to admit it looks better under there.

I did have to scrub the thread on the clutch cable and borrow a 1/2 inch unf tap to run through the wing nut before covering the thread in copper slip but it's free to turn now along its full length. I also had to make a tag and weld it to the torsion beam as the original had long since rotted off.

I did have to scrub the thread on the clutch cable and borrow a 1/2 inch unf tap to run through the wing nut before covering the thread in copper slip but it's free to turn now along its full length. I also had to make a tag and weld it to the torsion beam as the original had long since rotted off.

Exuptoy

Member

- Messages

- 3,133

- Location

- Maesteg, South Wales

Cut out 2 corroded sections of heat exchanger control cable tubes, bent and cut 2 x new tubes to fit and made a couple of sleeves out of the larger tubes and welded to the front sections which weren't corroded. Still need to paint them but stuck some etch primer on them for now.

Just the throttle cable tube now and that bits done.

Just the throttle cable tube now and that bits done.

HopefullySoon

Member

- Messages

- 783

- Location

- Heywood

The bus if it's not a keeper . (LOVE a t2 rebuild )

The mini .... my only experience of a mini is 2 young teenage ladies (one of them driving ) going to Blackpool....

It was a good night lol

The mini was on rails tho at 17 .... 850 cc

The mini .... my only experience of a mini is 2 young teenage ladies (one of them driving ) going to Blackpool....

It was a good night lol

The mini was on rails tho at 17 .... 850 cc

There might not be fossil fuel left to do it in retirement AND drive it.

There might not be fossil fuel left to do it in retirement AND drive it.