Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,915

- Location

- NE London - UK

when it happens we have to find someone to pin it on

Lovely machine once I'd fitted the modification that over came reflected light on shiny light surfaces stopping the filament feeding . printed a few trial parts for friends in PTEG and ABS here & there but nothing as complicated as the collet ....yet .How are you finding the MK3? After years of using a prety generic perspex frame Prusa clone (which has paid for itself many times over) I've recently ordered a MK3s - just waiting delivery.

Will do .... sometime tomorrow ., I'll start a new threadCan you let us have a pic, I'm trying to visualise your setup but it's getting late and my head's full of fog.

, " Vice Squad "

, " Vice Squad "

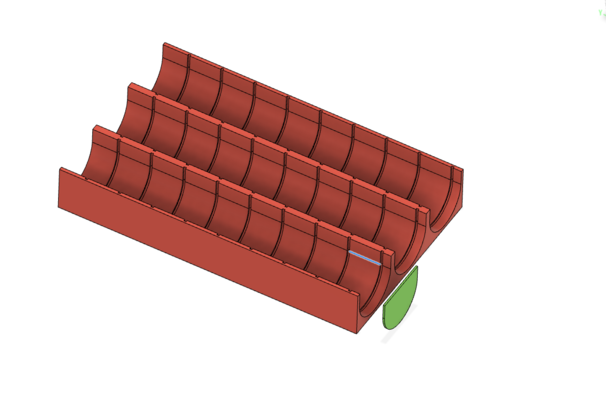

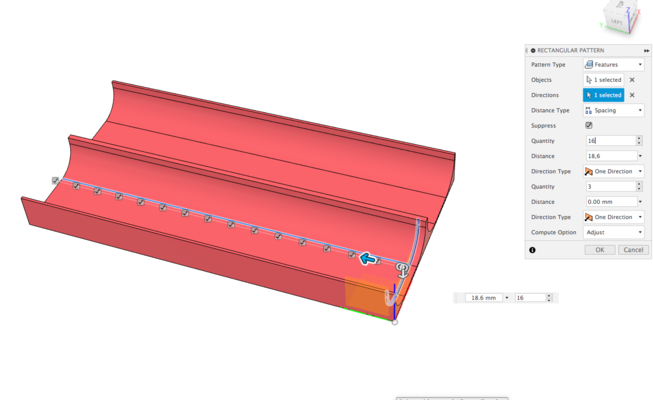

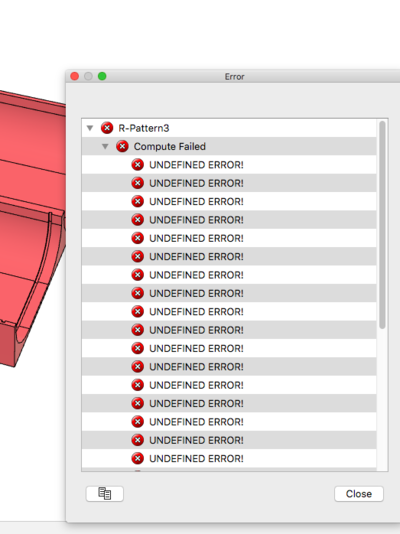

How did you create the main body?

If you are meaning my monkey metal shuttle , that's not a viable idea as it is also a sacrificial part , designed to be the weakest link if you crash the saddle or top slide etc. like I did .... saves bending or busting the lead screw or it anchored bearing end or also the stripping the teeth of the Zamack change gearsDrill number of holes required cut with hacksaw finish with a file. I would make it out of steel or brass.

How about machining it as two steel parts with a small brass pin transmitting the torque, that way when it breaks again you've only got to turn a little rod and reassemble rather than get a whole new casting made up.If you are meaning my monkey metal shuttle , that's not a viable idea as it is also a sacrificial part , designed to be the weakest link if you crash the saddle or top slide etc. like I did .... saves bending or busting the lead screw or it anchored bearing end or also the stripping the teeth of the Zamack change gears

I have thrown several bin bags full of those plastic Lista organisers

Bob

You must be a rich man then, they are quite expensive

How about machining it as two steel parts with a small brass pin transmitting the torque, that way when it breaks again you've only got to turn a little rod and reassemble rather than get a whole new casting made up.

It's a Sphere F10 circa 1943 built to the war departments requirement's it has 3 inch taper roller bearings the head stock spindle . It does not matter that the change gears are monkey metal it's the amount of lubrication and maintenance you do to them that matters . They were used by the Royal Navy boffins for torpedo development as they are a very good precision fine thread cutting lathe .It must be an Atlas- Craftsman- Acorn lathe or a clone. The change gears were also diecast, they were not a very good lathe. I've seen a couple with steel change gears.