ajlelectronics

Member

- Messages

- 11,138

- Location

- Gloucester, England

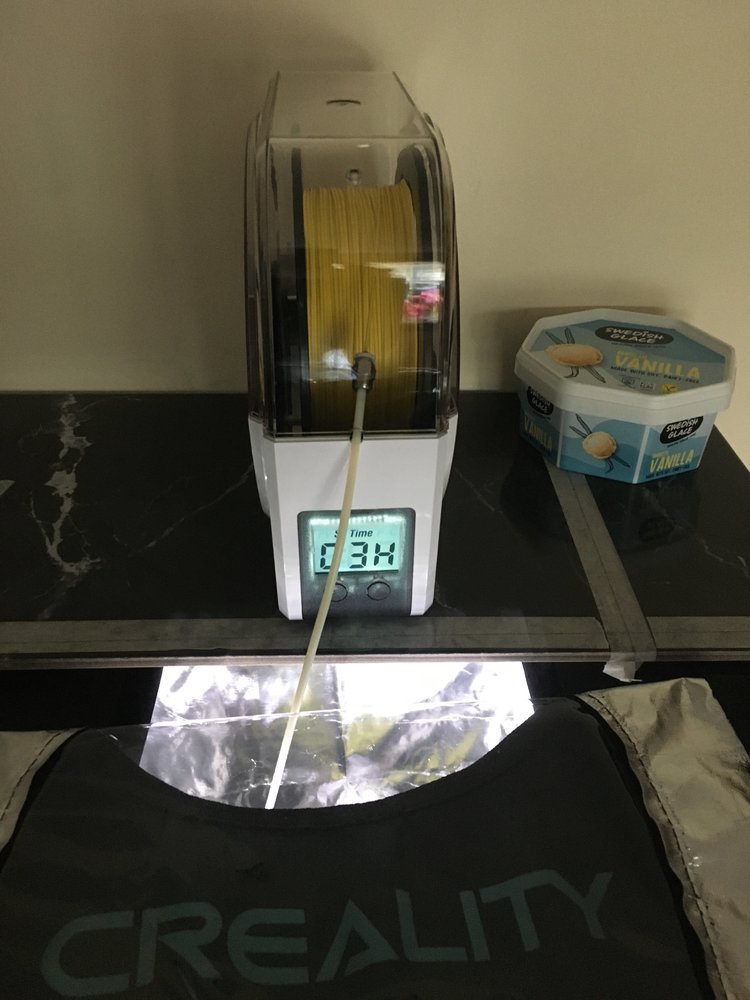

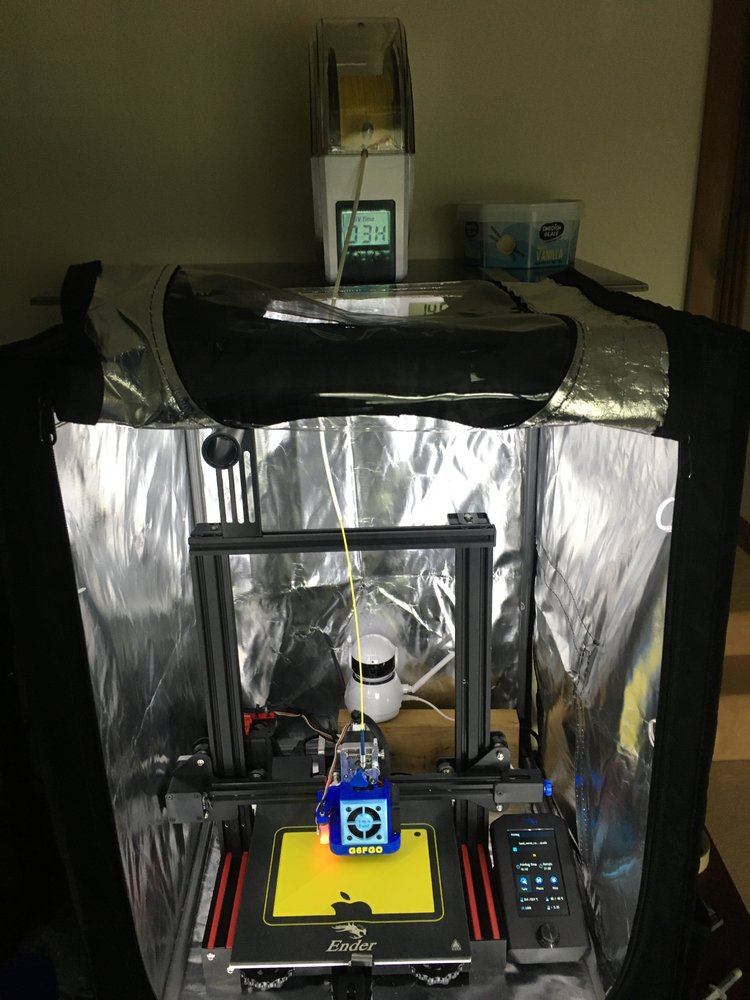

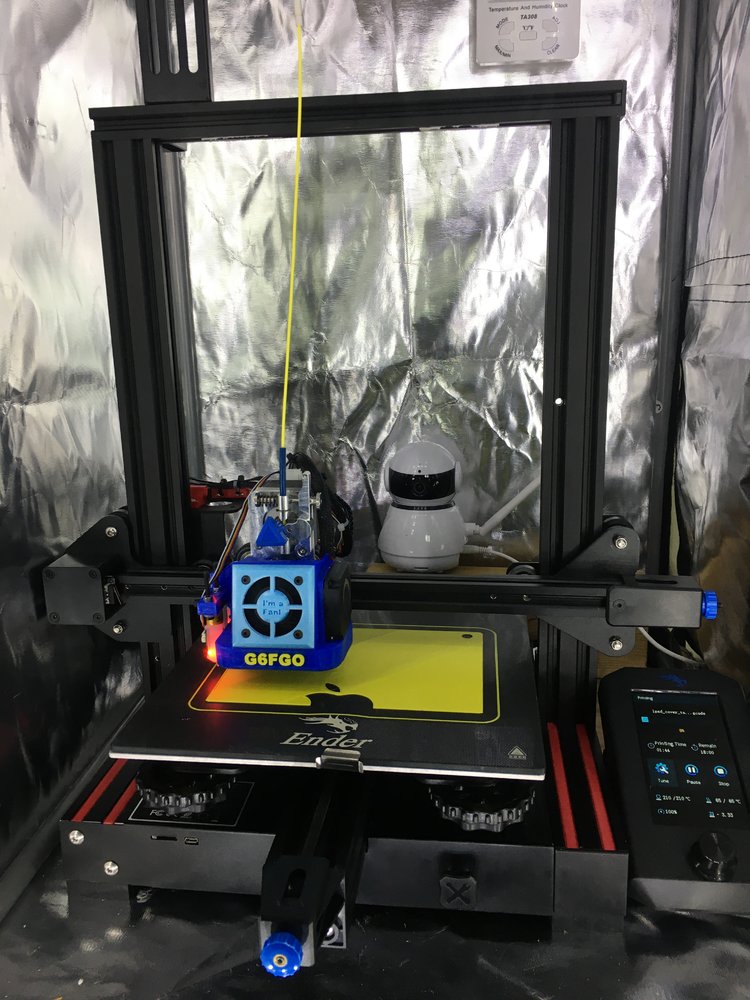

I have a filament dryer now. It is pretty poorly designed as standard, so I have done a quick mod that helps the filament exit smoothly. Seems to work and I think I can see an improvement in print quality. The mod is just the old Bowden tube and ferrule laid in the plain hole provided for exit of the filament.

Now I want to do something about the gantry height to give me back the original capability. With the Micro Swiss extruder, it fouls on the gantry when it gets too high. As it has dual Z drive, I need to keep the ends of the horizontal beam in situ. My idea is to get some pieces of extrusion and cut them to match the 40x20 uprights. Then fit a pair of short lenghts at right angles and then another slightly longer beam at the back. That should give the extruder room to move.

How do you joint the 20x20 extrusion at right angles?

Now I want to do something about the gantry height to give me back the original capability. With the Micro Swiss extruder, it fouls on the gantry when it gets too high. As it has dual Z drive, I need to keep the ends of the horizontal beam in situ. My idea is to get some pieces of extrusion and cut them to match the 40x20 uprights. Then fit a pair of short lenghts at right angles and then another slightly longer beam at the back. That should give the extruder room to move.

How do you joint the 20x20 extrusion at right angles?