What size box section are you using for the main frame? And the part the bearings roll across?Yes it does seem to be pretty similar. JD's has an additional two axes plus some kind of THC in the pipeline.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JD's Garage DIY CNC Plasma table build

- Thread starter GG1

- Start date

well no turning back now, Amazon is a bad place if your trying to keep your wallet firmly closed, ordered on sunday here on monday

im going to make a few changes to the sizes, plans as supplied give a cut area of 800mmx700mm im going smaller either 600x600mm or more likely 500mmx500mm, also im not putting the legs on it can sit on one of the benches and hang on the wall when not in use, ive looked back at what ive bought in from my local engineering firm over the last few years and nothing bigger than 200x200mm so i think i can live with 500x500 bed, given that 2mx1m is a stock sheet size i can get the stock holders to chop into 500mm squares, if it all works i can always biuld a 2mx1m bed another day,

and the plans call for 50x50x1.5mm box, im using 2mm wall for the y axis and 1.6mm wall for the x axis which is 200mm shorter than the plans

im going to make a few changes to the sizes, plans as supplied give a cut area of 800mmx700mm im going smaller either 600x600mm or more likely 500mmx500mm, also im not putting the legs on it can sit on one of the benches and hang on the wall when not in use, ive looked back at what ive bought in from my local engineering firm over the last few years and nothing bigger than 200x200mm so i think i can live with 500x500 bed, given that 2mx1m is a stock sheet size i can get the stock holders to chop into 500mm squares, if it all works i can always biuld a 2mx1m bed another day,

and the plans call for 50x50x1.5mm box, im using 2mm wall for the y axis and 1.6mm wall for the x axis which is 200mm shorter than the plans

GG1

Member

- Messages

- 138

- Location

- Dunblane, Scotland

What size box section are you using for the main frame? And the part the bearings roll across?

I'm making it all from 50x50x2, all I could get hold of locally.

GG1

Member

- Messages

- 138

- Location

- Dunblane, Scotland

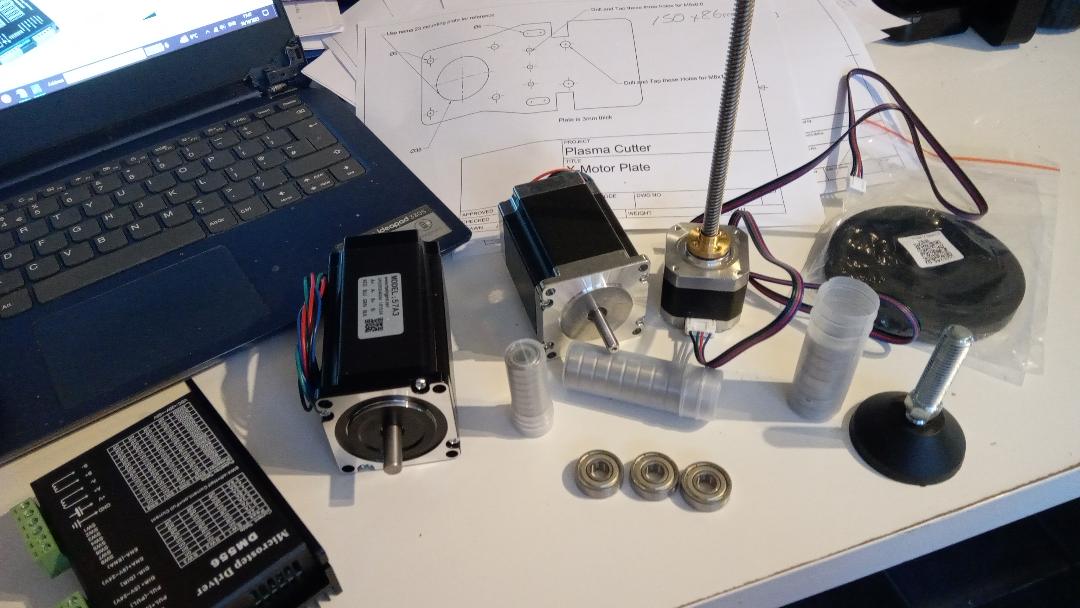

well no turning back now, Amazon is a bad place if your trying to keep your wallet firmly closed, ordered on sunday here on monday

im going to make a few changes to the sizes, plans as supplied give a cut area of 800mmx700mm im going smaller either 600x600mm or more likely 500mmx500mm, also im not putting the legs on it can sit on one of the benches and hang on the wall when not in use, ive looked back at what ive bought in from my local engineering firm over the last few years and nothing bigger than 200x200mm so i think i can live with 500x500 bed, given that 2mx1m is a stock sheet size i can get the stock holders to chop into 500mm squares, if it all works i can always biuld a 2mx1m bed another day,

and the plans call for 50x50x1.5mm box, im using 2mm wall for the y axis and 1.6mm wall for the x axis which is 200mm shorter than the plans

View attachment 421534

Welcome aboard...I'm sure you'll be making sparks long before me.

I'm probably being greedy going for a larger format - your way probably much more sensible, it would be simple to go bigger with all the hard work in the moving bits.

Misterg

Member

- Messages

- 1,609

- Location

- North Wales

Would one of the Lidl plasmas work with this?

I didn't see an answer to this - I know nothing about plasma cutters, (it's the internet, so that isn't any bar to passing comment!) but I understand that the HF start ones (which is what the Lidl one is AFAIK) cause too much interference to be used with CNC, and that what's needed is a 'blowback' start.

Hopefully we'll get an answer from someone who actually *knows*

sebring115

New Member

- Messages

- 22

Ther are links to a Dropbox or google drive from memory.I thought you could only get them via his patron channel?

sebring115

New Member

- Messages

- 22

But now seems you have to be a patron member but it’s not that expensiveTher are links to a Dropbox or google drive from memory.

GG1

Member

- Messages

- 138

- Location

- Dunblane, Scotland

Hopefully we'll get an answer from someone who actually *knows*

I'm afraid you're out of luck with an answer from me - for what it's worth I'm going against a lot of advice I have seen and will use a cheapo HF start on my build - using shielding, filtering and proper grounding to mitigate for the noise.

Please bear in mind I've never even used a plasma cutter and only know enough about electronics to be dangerous, but I believe it can work. Whether I can make it work remains to be seen.

That's it pretty much in a nutshell.I didn't see an answer to this - I know nothing about plasma cutters, (it's the internet, so that isn't any bar to passing comment!) but I understand that the HF start ones (which is what the Lidl one is AFAIK) cause too much interference to be used with CNC, and that what's needed is a 'blowback' start.

Hopefully we'll get an answer from someone who actually *knows*

HF does work, but you have to be on top of handling the generated interference.

It's one of these things, that you can seem to do everything perfectly, yet still have endless problems, whereas you can haphazardly throw a system together breaking every rule and it works flawlessly.

You won't know until you try.

Well l don't know eitherHopefully we'll get an answer from someone who actually *knows*

But l think mine will have a felt tip pen where the torch should be and when and only when I can draw stuff up and draw it out on the table will I put a torch in it and then if it starts playing up l will know where to look

it did cross my mind to power it off 2 12v leisure batteries but l think the interference comes from the plasma striking the arc, hence why im going to run mine as a plotter first and see if it will draw ok, if i then get trouble when i add the plasma cutter i will know where its come from and will have to shield or use a different plasma from the R Tech i haveThe CNC aspect can't use much power. I wonder if the easiest solution is to run it on a leisure battery while running the plasma off the mains? Or does the interference happen somewhere else?

im not so sure i will be making sparks before you drawings maybe lol, ive got a lot of other things on the go including building a new garage/workshop to put the plasma in, if it was 5 years ago i would be wanting an 8x4' table but ive mellowed a bit, my local engineering shop bought a cnc plasma with an 8x4 table and i was able to pop in with bits of cardboard and they would do my bits and bobs in a day or two for a few pounds, one thing i noticed over the last few years is how most items they made on it were only small and the 8x4 table was hardly ever used just the one end, it did however become a bench for all sorts of other things, finished jobs were stacked on it tools materials all lived on it, sometimes when i would call in it was completely covered with stuff and they would say " not this week" well eventually they decided the real estate it was sitting on was worth more to them than the plasma so it was sold off and they now out source to a laser company, hence my desire to biuld one and as they only ever used a small section of the bed im going to make mine 500 sqWelcome aboard...I'm sure you'll be making sparks long before me.

I'm probably being greedy going for a larger format - your way probably much more sensible, it would be simple to go bigger with all the hard work in the moving bits.

im also thinking of welding most of it together rather than all those bolts including the x axis arm onto the 70mm carrier, can you see any issues with doing that ?

That wouldn't really help.The CNC aspect can't use much power. I wonder if the easiest solution is to run it on a leisure battery while running the plasma off the mains? Or does the interference happen somewhere else?

The issue is interference being induced in the control circuit wiring, with EMF and ground loops being the biggest issues.

EMF (VFD outputs and Plasma are good sources) can generate voltage in any wire not suitably shielded, and Ground Loops can cause voltage to appear where you don't want it.

Commercial machines avoid most issues by using 24V control circuit voltages for the basic inputs/outputs, and some form of differential control signals for faster signals, however when your main selling point is "Build this for under £xxx!", it's going to push the cost up substantially.

GG1

Member

- Messages

- 138

- Location

- Dunblane, Scotland

I'll also be welding most of it together, with the exception of the Y axis double rails, X arm and X bearing support rail. Partly because I don't want to put heat into what are pretty straight tubes, but also because I'm impatient and have already blued the rails...im also thinking of welding most of it together rather than all those bolts including the x axis arm onto the 70mm carrier, can you see any issues with doing that ?

I guess if you weld the X arm onto the carrier it'll be a bit more tricky to take it off if you want to go bigger one day, but probably only needs a few stitches anyway.

Funny how your local firm is not immune to The Law of Flat Surfaces.

I'm doing exactly the same ref building a new workshop so it might be a race of the tortoise and the tortoise.

Funny how your local firm is not immune to The Law of Flat Surfaces.

I'm doing exactly the same ref building a new workshop so it might be a race of the tortoise and the tortoise.

never heard about the law of flat surfaces but i can see the idea

they always used to quote me something that Aristotle came up with

" nature abhors a vacuum" and its so true dosent matter if its your garage your workshop or your shed as soon as you have some empty space it fills up as if by magic , well thats what i find anyway

Aristotle coined the phrase “nature abhors a vacuum,” but a team of Tulane University researchers says their latest study proves there are exceptions to the rule. The phrase expresses the idea that unfilled spaces go against the laws of nature and physics and that every space needs to be filled with something.

so get on ebay or amazon and start filling

sebring115

New Member

- Messages

- 22

sebring115

New Member

- Messages

- 22

i might do something similar to that and im still considering whether to weld or bolt on the x arm to the carrier. as you say if its bolted it adjustableIt’s worth making the x axis removable so you can adjust for square and also if you want to pack it away it’s a smaller footprint. I have welded the plates onto the end for the bearing carrier and skimmed them flat though.

View attachment 421701

are there limit switches ? i was looking for them in the plans but couldn't find themJust talking about control box and 24v, here is mine, 24v latching relay for the E stop and also the torch height and limits if I bother with them, interfaced with an opto isolator board and will use Nc contacts. The box is an angle grinder box I had.

View attachment 421702 View attachment 421703

GG1

Member

- Messages

- 138

- Location

- Dunblane, Scotland

How powerful are the motors you are using? JD's said they didn't bother with limit switches as the sizes they use just stall and do no damage when crashed.Just talking about control box and 24v, here is mine, 24v latching relay for the E stop and also the torch height and limits if I bother with them, interfaced with an opto isolator board and will use Nc contacts. The box is an angle grinder box I had.

View attachment 421702 View attachment 421703