when ime not welding ime mole catching, just over 20,000 in 5 years....old ways are the best!I'll bet there are a lot of moles out that that are thankful for that

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lead welding

- Thread starter Water skier 16

- Start date

brightspark

Member

- Messages

- 41,356

- Location

- yarm stockton on tees

scissor trapswhen ime not welding ime mole catching, just over 20,000 in 5 years....old ways are the best!

ive caught a fair few. traps probing rod and a trowel. chuck em in some soil outside for a week till rusty and the smell of your hands disappear wear gloves and go out setting

ive caught a fair few. traps probing rod and a trowel. chuck em in some soil outside for a week till rusty and the smell of your hands disappear wear gloves and go out setting

davidjohnperry

a different breed

- Messages

- 2,475

- Location

- yate/bristol

I've done lead welding in college I actually did the last year Bristol college taught it have not done it in years tho kinda miss doing it to be honest

If I find my old camera I have some pics

If I find my old camera I have some pics

davidjohnperry

a different breed

- Messages

- 2,475

- Location

- yate/bristol

Dcal

Member

- Messages

- 4,069

- Location

- Antrim Northern Ireland

Here's my attempts.

I'm fixing my chimneys and as I need to have a very small bit of leads flashing welded, I decided to try and do it myself and so needed to learn how to burn lead.

I bought a torch second hand on ebay that was supposed to be for welding lead but the only nozzle that came with it was far too big and I couldn't keep the lead off the floor. I could sort of make a joint but it was more casting than welding. It didn't help that there were no valves on the torch and I had to adjust the flame with the regulators.

I've a mate who's a jeweler and he lent me a spare torch of the type they use.

It came with a no 5 and 6 nozzle and although it was a bit bit more controllable (and had knobs) I still couldn't get the torch where I needed it without it melting the edge of the lead.

Again I could sort of make a joint but it was a really wide bead and again mostly ended on the floor.

Luckily he had a no 3 nozzle and with that I was able to get a lot more control.

So had a go of an hour or so tonight and here are my first attempts with the smaller nozzle.

Below is a lap joint using an in and out dab method (Oxy Acetylene gas)

I could make a joint but found it very hard to be in anyway consistent.

Part of the problem is the cleanliness of the lead. There seems to be a grain with the lead. It would scrape clean easily with a chisel in one direction but not the other. Is this just me or do others find the same?

I found a stainless wire brush made a better job of cleaning it and the "rods" but that might just be because I'm lazy.

If I used a backing plate (easy on the bench and for the bit of flashing I need to make) I was able to just run a bead instead of the series of tacks.

Again not pretty or consistent but a better joint I think.

So ran a lot of beads for practice. The second runs, perpendicular to the first, were much easier because of the increased thickness of the lead.

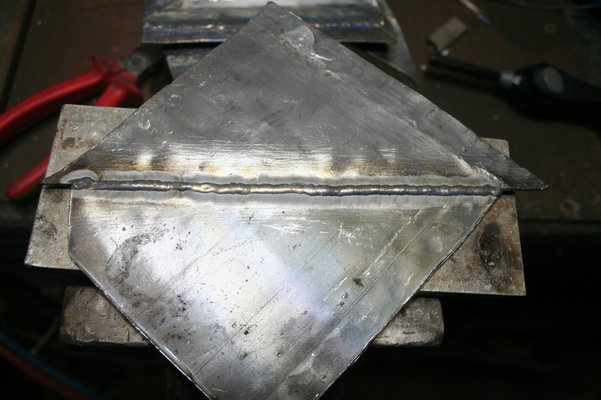

Final practice for tonight is a butt joint on an aluminum backing plate. (You can see the torch and rods cut from the lead sheet I'm using)

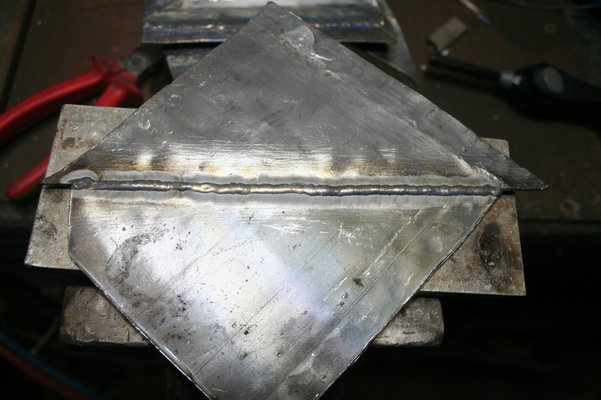

Underside, showing very little penetration but I am only learning.

Welded the underside as well and it was a lot easier to control when the edges are fused.

All in all I'm pretty happy with the progress.

Any comments / hints welcome before I go for the real thing.

I think I should be able to weld what I need on the bench, it would be different matter upside down on a roof.

I'm fixing my chimneys and as I need to have a very small bit of leads flashing welded, I decided to try and do it myself and so needed to learn how to burn lead.

I bought a torch second hand on ebay that was supposed to be for welding lead but the only nozzle that came with it was far too big and I couldn't keep the lead off the floor. I could sort of make a joint but it was more casting than welding. It didn't help that there were no valves on the torch and I had to adjust the flame with the regulators.

I've a mate who's a jeweler and he lent me a spare torch of the type they use.

It came with a no 5 and 6 nozzle and although it was a bit bit more controllable (and had knobs) I still couldn't get the torch where I needed it without it melting the edge of the lead.

Again I could sort of make a joint but it was a really wide bead and again mostly ended on the floor.

Luckily he had a no 3 nozzle and with that I was able to get a lot more control.

So had a go of an hour or so tonight and here are my first attempts with the smaller nozzle.

Below is a lap joint using an in and out dab method (Oxy Acetylene gas)

I could make a joint but found it very hard to be in anyway consistent.

Part of the problem is the cleanliness of the lead. There seems to be a grain with the lead. It would scrape clean easily with a chisel in one direction but not the other. Is this just me or do others find the same?

I found a stainless wire brush made a better job of cleaning it and the "rods" but that might just be because I'm lazy.

If I used a backing plate (easy on the bench and for the bit of flashing I need to make) I was able to just run a bead instead of the series of tacks.

Again not pretty or consistent but a better joint I think.

So ran a lot of beads for practice. The second runs, perpendicular to the first, were much easier because of the increased thickness of the lead.

Final practice for tonight is a butt joint on an aluminum backing plate. (You can see the torch and rods cut from the lead sheet I'm using)

Underside, showing very little penetration but I am only learning.

Welded the underside as well and it was a lot easier to control when the edges are fused.

All in all I'm pretty happy with the progress.

Any comments / hints welcome before I go for the real thing.

I think I should be able to weld what I need on the bench, it would be different matter upside down on a roof.

gaz1

Member

- Messages

- 20,407

- Location

- westyorkshire

to get it even flatter retouch over it reheating so it becomes a more uniformed flatish sheet

a normal blowlamp can be used if soldering lead

on another note soldering was also done on very old blowlamps

@Burdekin a reference for you to take note

there wasnt oxy/ accet at one time but lead welding is a really old lost art form

Last edited:

gaz1

Member

- Messages

- 20,407

- Location

- westyorkshire

I beg to differ I and many people have dealt with lead on very old propertys it will outlast many other styles including copper

welding lead isnt a proven track record not for a very long time

to be honest with you it looks awful compared to flat lead

its got to stage cost vs whats right to install many refuse to use lead due to its expensive costs these days

ive walked in lead valleys where 2 people can pass within the valley

welding lead isnt a proven track record not for a very long time

to be honest with you it looks awful compared to flat lead

its got to stage cost vs whats right to install many refuse to use lead due to its expensive costs these days

ive walked in lead valleys where 2 people can pass within the valley

I beg to differ I and many people have dealt with lead on very old propertys it will outlast many other styles including copper

What has that to do with what I explained? I worked with lead near 50 yrs ago on Glasgow Cathedral and that is built 12th Century!

welding lead isnt a proven track record not for a very long time

That is mince!

to be honest with you it looks awful compared to flat lead

You haven't seen it done proper by real experts then. It is like fine herring bone and a thing of beauty.

ive walked in lead valleys where 2 people can pass within the valley

Really? I have laid those valleys and flat roofs on listed buildings where the only way up with huge rolls of lead was with a crane. I am a time served old fashioned Slater of the 60's, all my days at it and my Father was a Steeplejack. who I worked with since I was 15. I didn't just come upon this type of work as I strolled along.

You want to try something? When fitting a window into a Dormer with vertical slating, you put a lead tray on the sill. Dress that lead into a box shape for the window to sit in and on. You will stretch the lead at inside corners on each side, as you try to get lead to go 3 ways. If it doesn't burst there and then, it will crack sooner rather than later and leak. You weld the joints to make that inside shape for window to sit in, with separate lead sections. I have replaced scores of them, when "builders" have bossed lead into that corner and stretched it till thin. The reason most builders don't weld lead is that they don't have the tools or skill. It was only ever about 10 per cent of Plumbers who could lead weld. If you think that a Bossed and folded chimney tray is superior to a welded one.............................why did they bother welding them? To avoid stretching the lead, that's why

What has that to do with what I explained? I worked with lead near 50 yrs ago on Glasgow Cathedral and that is built 12th Century!

welding lead isnt a proven track record not for a very long time

That is mince!

to be honest with you it looks awful compared to flat lead

You haven't seen it done proper by real experts then. It is like fine herring bone and a thing of beauty.

ive walked in lead valleys where 2 people can pass within the valley

Really? I have laid those valleys and flat roofs on listed buildings where the only way up with huge rolls of lead was with a crane. I am a time served old fashioned Slater of the 60's, all my days at it and my Father was a Steeplejack. who I worked with since I was 15. I didn't just come upon this type of work as I strolled along.

You want to try something? When fitting a window into a Dormer with vertical slating, you put a lead tray on the sill. Dress that lead into a box shape for the window to sit in and on. You will stretch the lead at inside corners on each side, as you try to get lead to go 3 ways. If it doesn't burst there and then, it will crack sooner rather than later and leak. You weld the joints to make that inside shape for window to sit in, with separate lead sections. I have replaced scores of them, when "builders" have bossed lead into that corner and stretched it till thin. The reason most builders don't weld lead is that they don't have the tools or skill. It was only ever about 10 per cent of Plumbers who could lead weld. If you think that a Bossed and folded chimney tray is superior to a welded one.............................why did they bother welding them? To avoid stretching the lead, that's why

I used killed Nitric acid as a flux an old tin smith gave me a pint in a glass stoppered bottle (it is not nice stuff) but it made the lead job almost easy. I expect there is another less dangerous stuff today.

The soldering flux known as "killed spirits" is a solution of zinc chloride. It can be made by dissolving pieces of scrap zinc in dilute hydrochloric acid. It is ( still ) available commercially as "Baker's Fluid".

roofman

Purveyor of fine English buckets and mops

- Messages

- 12,982

- Location

- North West with water on 3 sides

A very knowledgeable postI beg to differ I and many people have dealt with lead on very old propertys it will outlast many other styles including copper

What has that to do with what I explained? I worked with lead near 50 yrs ago on Glasgow Cathedral and that is built 12th Century!

welding lead isnt a proven track record not for a very long time

That is mince!

to be honest with you it looks awful compared to flat lead

You haven't seen it done proper by real experts then. It is like fine herring bone and a thing of beauty.

ive walked in lead valleys where 2 people can pass within the valley

Really? I have laid those valleys and flat roofs on listed buildings where the only way up with huge rolls of lead was with a crane. I am a time served old fashioned Slater of the 60's, all my days at it and my Father was a Steeplejack. who I worked with since I was 15. I didn't just come upon this type of work as I strolled along.

You want to try something? When fitting a window into a Dormer with vertical slating, you put a lead tray on the sill. Dress that lead into a box shape for the window to sit in and on. You will stretch the lead at inside corners on each side, as you try to get lead to go 3 ways. If it doesn't burst there and then, it will crack sooner rather than later and leak. You weld the joints to make that inside shape for window to sit in, with separate lead sections. I have replaced scores of them, when "builders" have bossed lead into that corner and stretched it till thin. The reason most builders don't weld lead is that they don't have the tools or skill. It was only ever about 10 per cent of Plumbers who could lead weld. If you think that a Bossed and folded chimney tray is superior to a welded one.............................why did they bother welding them? To avoid stretching the lead, that's why

...a chimney back box that's been welded as apposed to stretching it around 90 corners will last 10 times longer and ive been in this game almost 45 years myself, and that's roofing every day of those years too. My lead man retired who i used for over 30 years for my pre-made boxes and pipe slates so when ever i find old Victorian lead bay roofs i don't cash the lead in as i use it on chimney back boxes as it seems a lot more forgiving than modern lead when dressed around sharp 90,s and seems the next best thing to welded boxes..There does seem to be some terrible quality rolled lead these days

...a chimney back box that's been welded as apposed to stretching it around 90 corners will last 10 times longer and ive been in this game almost 45 years myself, and that's roofing every day of those years too. My lead man retired who i used for over 30 years for my pre-made boxes and pipe slates so when ever i find old Victorian lead bay roofs i don't cash the lead in as i use it on chimney back boxes as it seems a lot more forgiving than modern lead when dressed around sharp 90,s and seems the next best thing to welded boxes..There does seem to be some terrible quality rolled lead these days  ...Ive tried making my own boxes but although they seem water tight they look terrible so i admit i cant weld lead

...Ive tried making my own boxes but although they seem water tight they look terrible so i admit i cant weld lead

Dcal

Member

- Messages

- 4,069

- Location

- Antrim Northern Ireland

Bit of an update on my efforts.

I tried folding the lead with my folder, (it's set up for 1mm body tin) and it stretched and tore the lead in the outside corner of the fold.

Just reverted to hammering it over a bit of wood and got a much better bend.

To my untrained eye this young fella seems to have the knack

For the hell of it I tried welding a fillet on the flat and I could sort of manage it but struggled with undercutting the top of the fillet, that might be why a series of tacks seems to be the preferred option.

Vertical up is way beyond my skill level and I've no idea how anyone would be able to weld an overhead butt joint.

I tried folding the lead with my folder, (it's set up for 1mm body tin) and it stretched and tore the lead in the outside corner of the fold.

Just reverted to hammering it over a bit of wood and got a much better bend.

To my untrained eye this young fella seems to have the knack

For the hell of it I tried welding a fillet on the flat and I could sort of manage it but struggled with undercutting the top of the fillet, that might be why a series of tacks seems to be the preferred option.

Vertical up is way beyond my skill level and I've no idea how anyone would be able to weld an overhead butt joint.