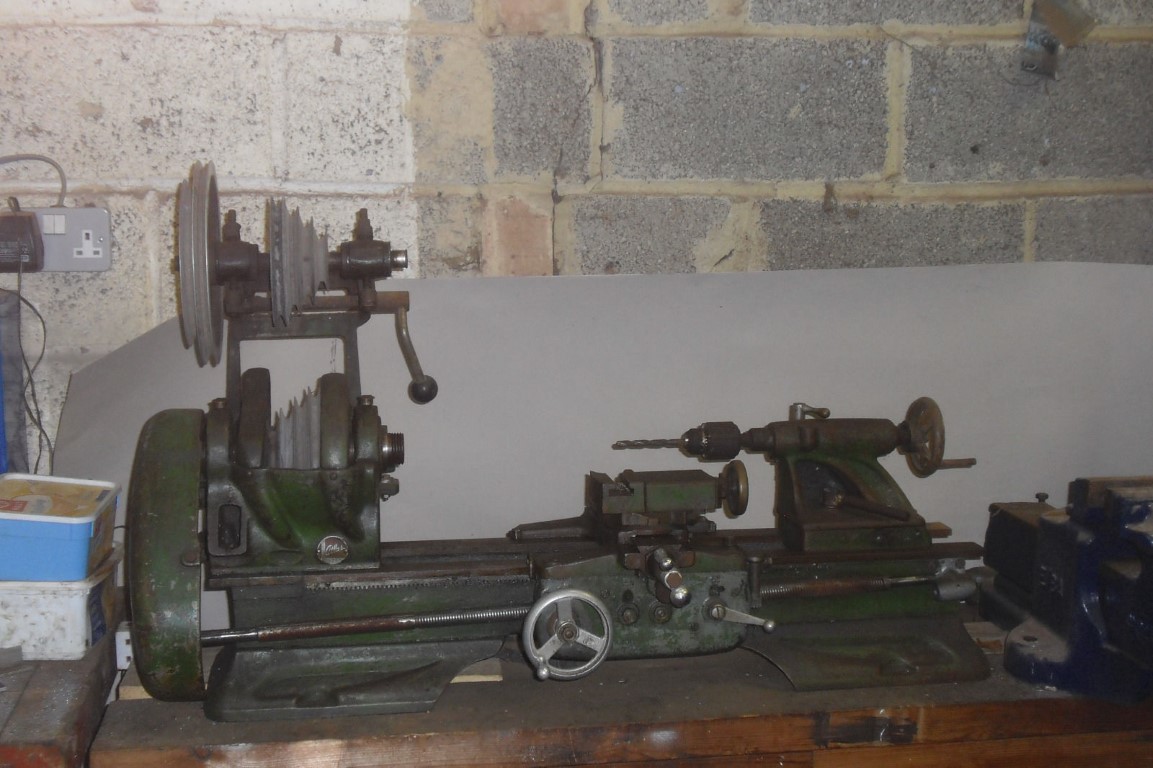

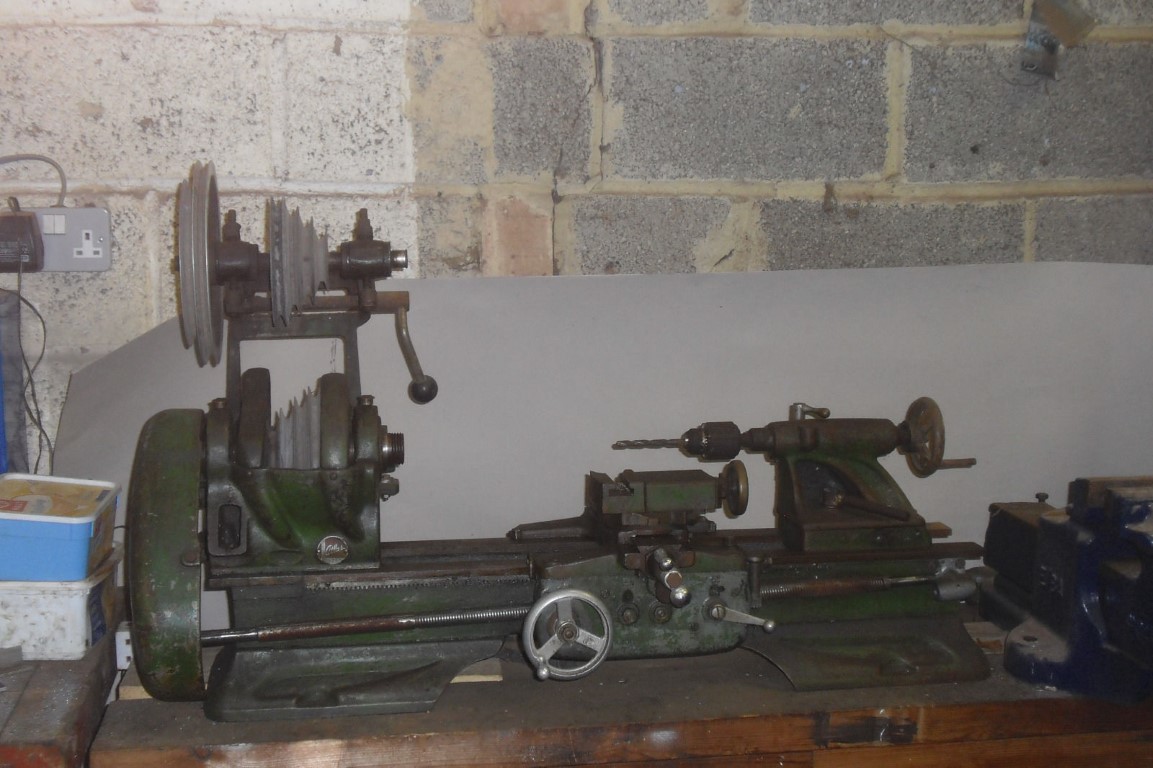

Last autumn I picked up an incomplete Atlas 10f lathe, with the intention to only use the lathe bed for a CNC project. However, when i got it home, it turned out that the headstock bearings etc were actually in quite decent nick, so as it came with the countershafts, saddle, headstock etc, I thought I might restore it up to usable condition and then decide how to proceed with the CNC project.

It's a real slow project, as I basically only have an hour here and there to play in the garage, and there's hundreds of other projects taking time as well.

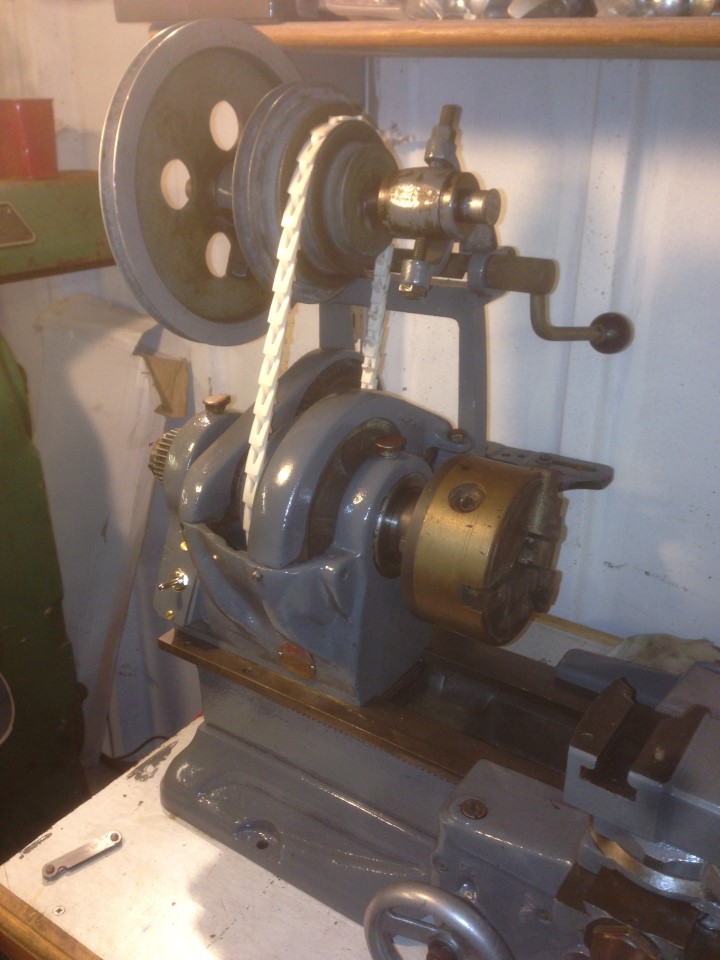

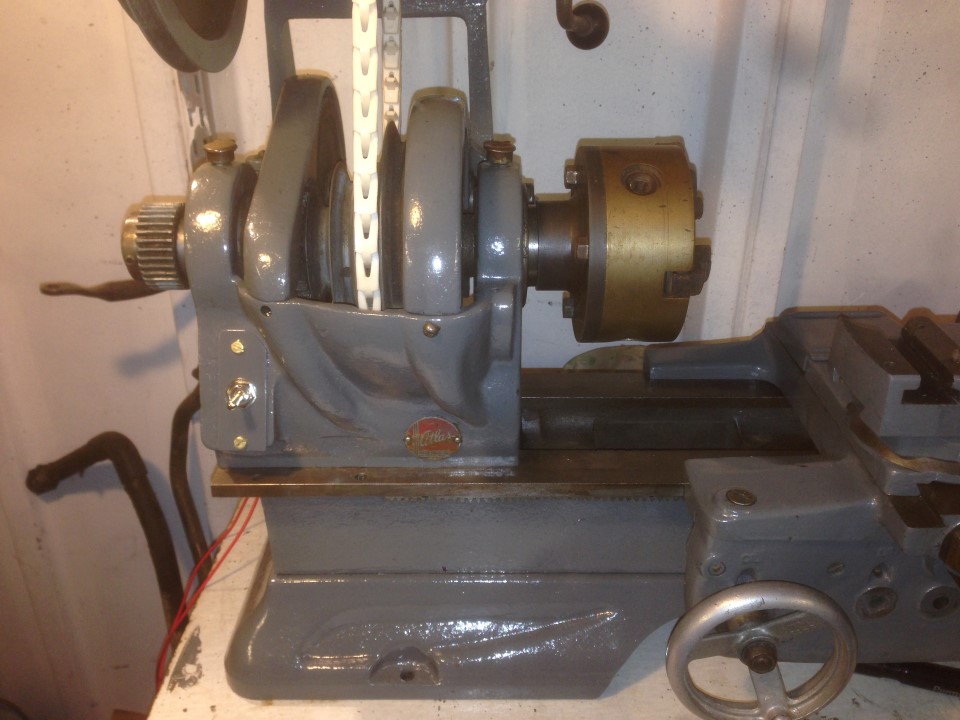

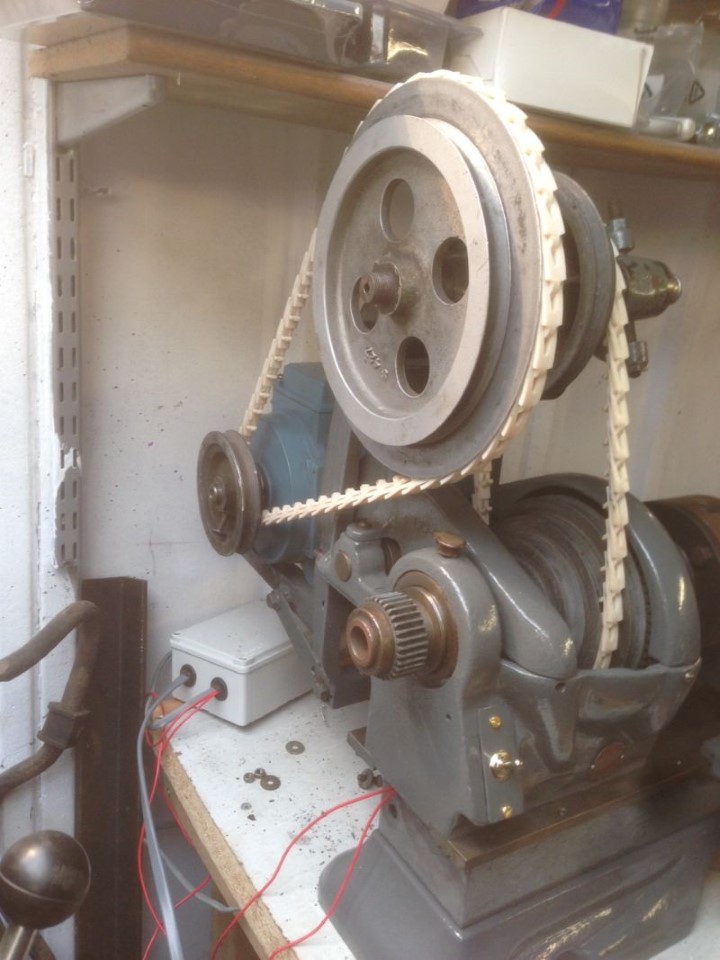

Anyway, enough of that. Here are some pics of what it looked like when I got it home:

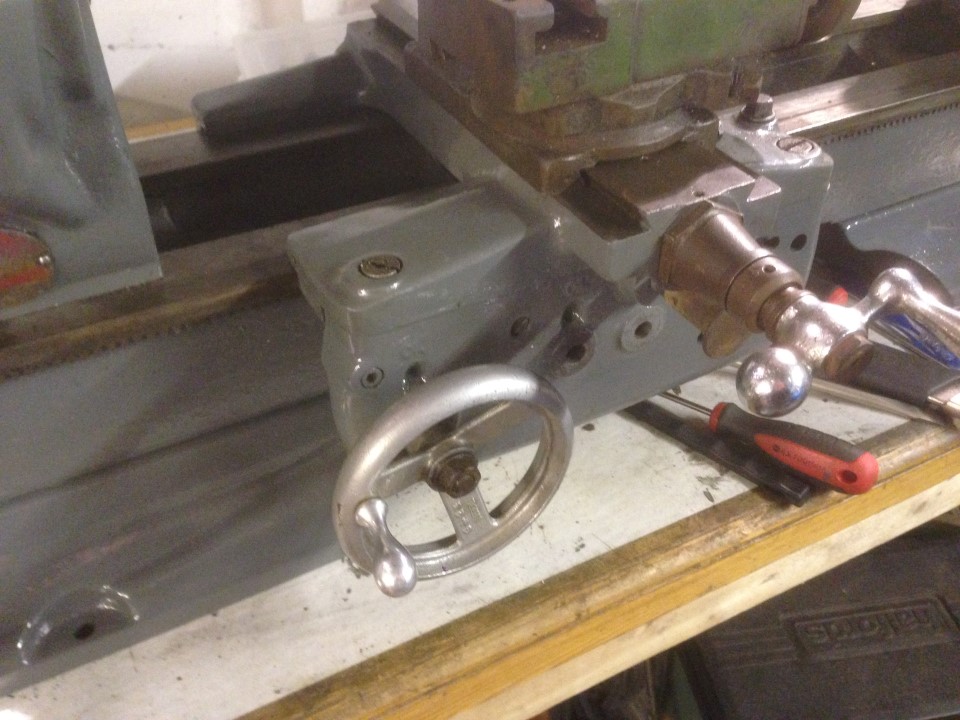

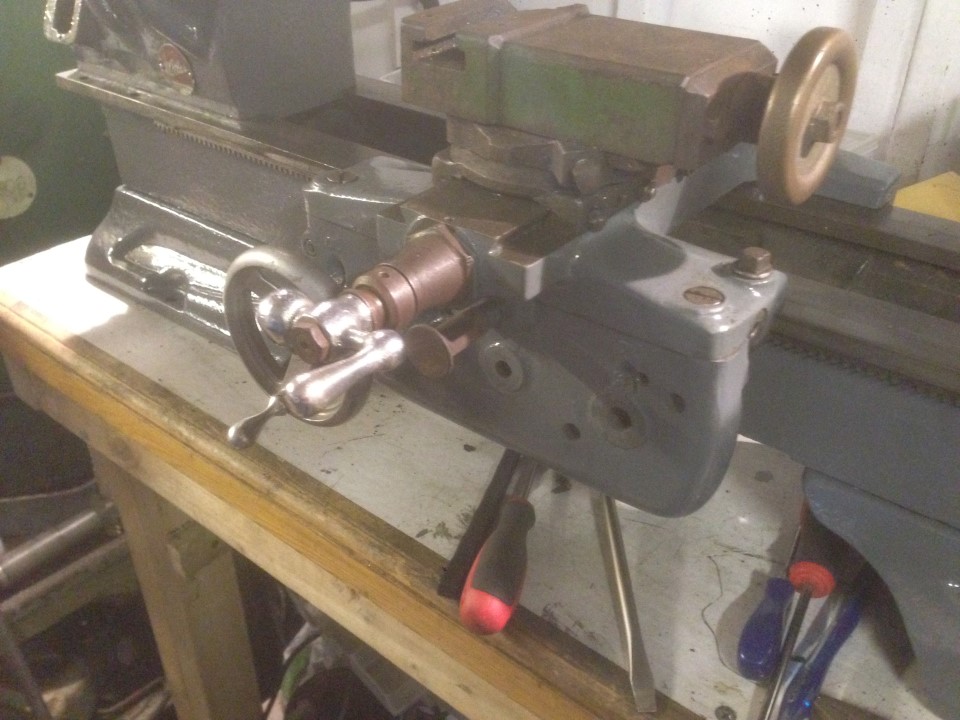

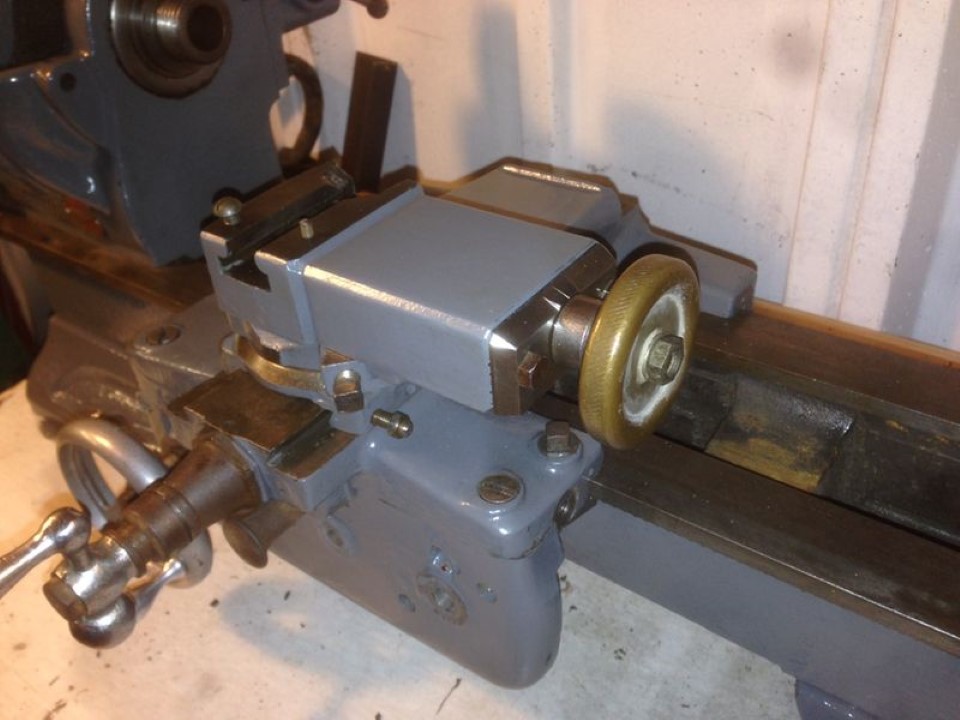

I've since stripped it mainly to bits, and treated most metal bits using the electrolytic rust removal process. It has worked better than I anticipated. The barrel in the tailstock was originally so rusted that it wouldnt' move in and out, but after chucking it in the bath for a week, it's now bright again, and even the original etched scale can be easily read.

The lathe bed was also totally rusted towards the tailstock end (to the point of the tailstock binding). This was treated using a custom built wooden box with a cut up binliner as a waterproof membrane. Again, it is now in really quite decent nick from a rust point of view.

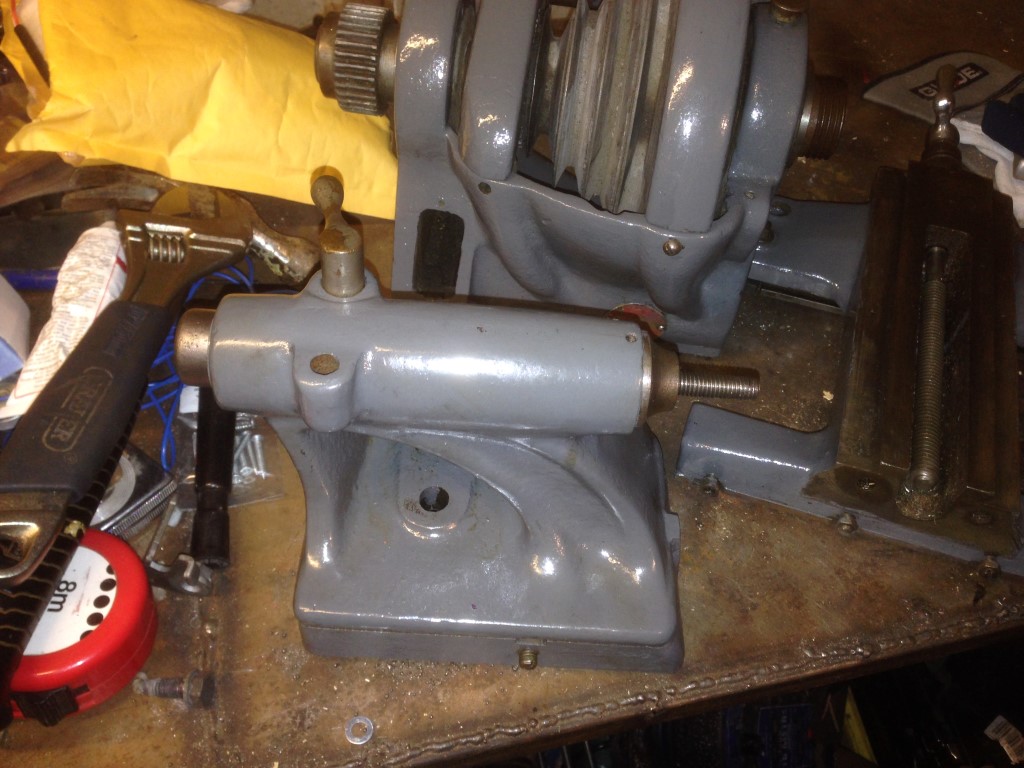

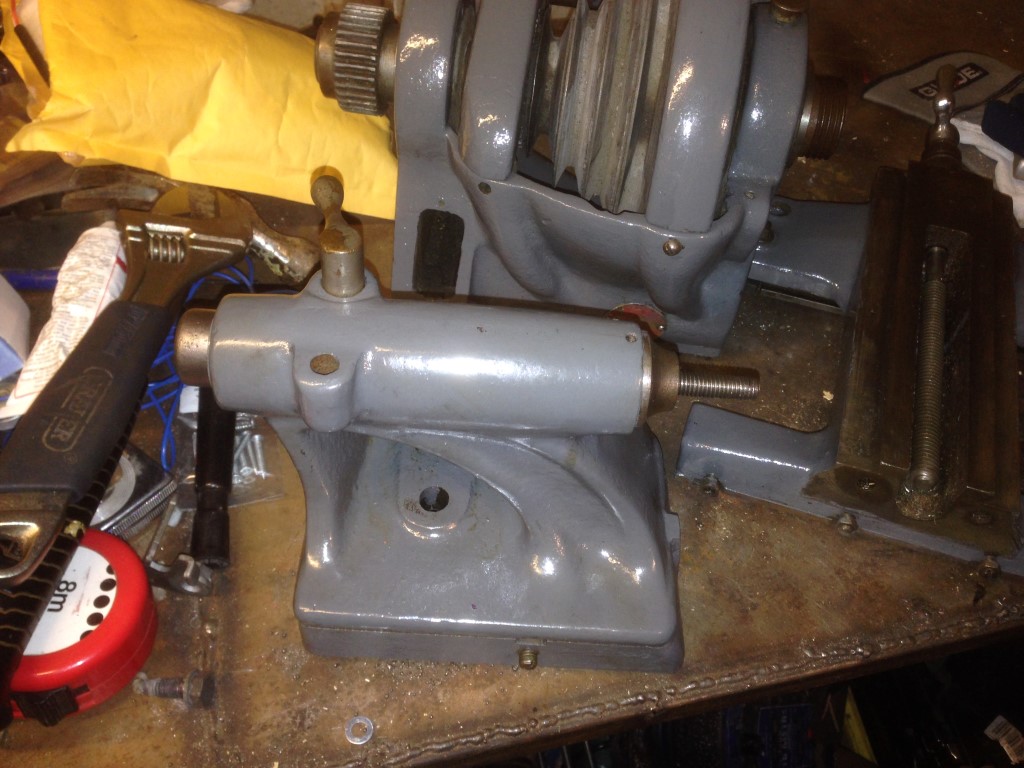

I've also started painting it using Massey Ferguson grey enamel paint - it's really good stuff. I'm not claiming to be the best painter out there, but at least it looks much much better than when I got it home.

Plan now is to bolt it back together and see what it's like in use.

The cross slide leadscrew is lose in its bearing, so it's not "nice and smooth" to use, so that will need attention, however it doesn't affect initial operations so will remain as it is for now. The screw and nut seem to be in good condition, however I'll probably replace these with a metric version when I replace the bearing and do a rebuild of the saddle.

The main leadscrew had significant wear, and I also broke the rear mounting bracked for it, so I've got myself some 14x2mm trapezoidal rod to replace it. This is not required for manual operation, so will remain broken for a while whilst I try the lathe out.

I need to use this lathe to make a bushing for my drummond round bed's countershaft, hence the urgency to get it working again, and minimal work to get it "up and running" at present.

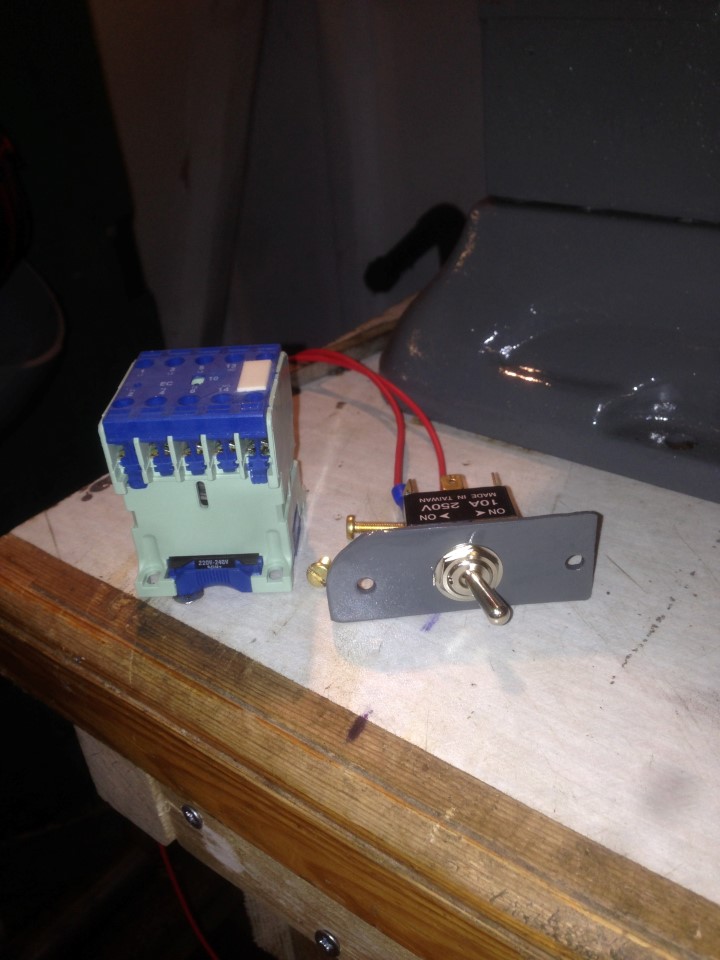

Long term plan is to mount the new main lead screw and drive it through an Arduino controller and basically implement some form of electronic leadscrew. Once I have that working, I will probably add a stepper to the cross slide too and make it fully cnc'd, but I think the electronic lead screw would be a good half way house to aim for at first, as it will let me do fine feeds and metric/imperial screw cutting easily.

It's a real slow project, as I basically only have an hour here and there to play in the garage, and there's hundreds of other projects taking time as well.

Anyway, enough of that. Here are some pics of what it looked like when I got it home:

I've since stripped it mainly to bits, and treated most metal bits using the electrolytic rust removal process. It has worked better than I anticipated. The barrel in the tailstock was originally so rusted that it wouldnt' move in and out, but after chucking it in the bath for a week, it's now bright again, and even the original etched scale can be easily read.

The lathe bed was also totally rusted towards the tailstock end (to the point of the tailstock binding). This was treated using a custom built wooden box with a cut up binliner as a waterproof membrane. Again, it is now in really quite decent nick from a rust point of view.

I've also started painting it using Massey Ferguson grey enamel paint - it's really good stuff. I'm not claiming to be the best painter out there, but at least it looks much much better than when I got it home.

Plan now is to bolt it back together and see what it's like in use.

The cross slide leadscrew is lose in its bearing, so it's not "nice and smooth" to use, so that will need attention, however it doesn't affect initial operations so will remain as it is for now. The screw and nut seem to be in good condition, however I'll probably replace these with a metric version when I replace the bearing and do a rebuild of the saddle.

The main leadscrew had significant wear, and I also broke the rear mounting bracked for it, so I've got myself some 14x2mm trapezoidal rod to replace it. This is not required for manual operation, so will remain broken for a while whilst I try the lathe out.

I need to use this lathe to make a bushing for my drummond round bed's countershaft, hence the urgency to get it working again, and minimal work to get it "up and running" at present.

Long term plan is to mount the new main lead screw and drive it through an Arduino controller and basically implement some form of electronic leadscrew. Once I have that working, I will probably add a stepper to the cross slide too and make it fully cnc'd, but I think the electronic lead screw would be a good half way house to aim for at first, as it will let me do fine feeds and metric/imperial screw cutting easily.