I think the belt is on backwards Henrik.

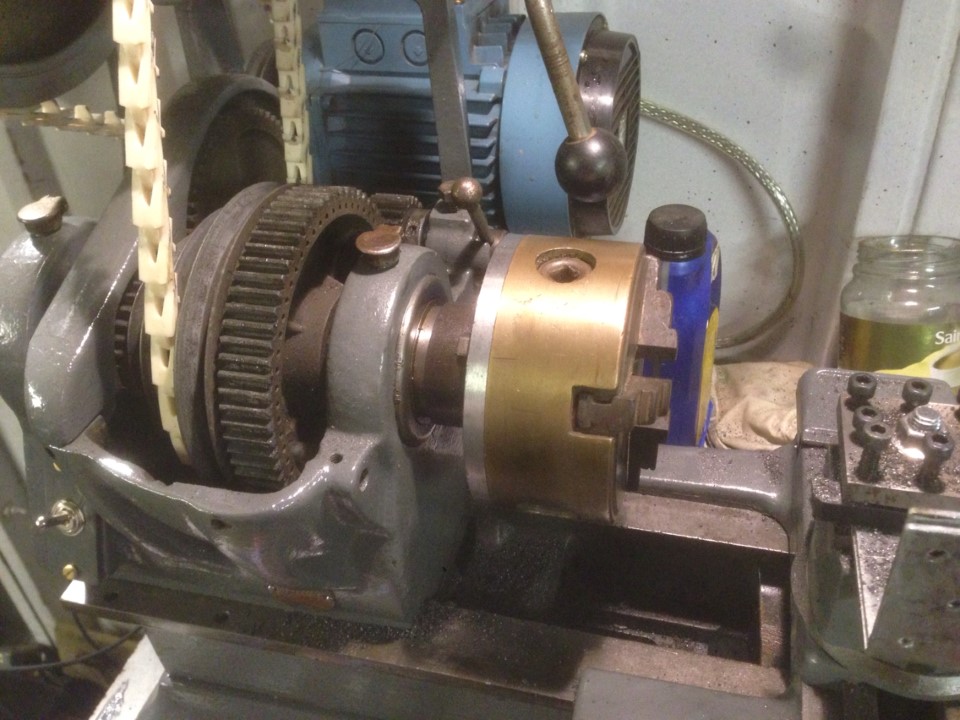

My Atlas also had a wobbly back-plate. I un-bolted the chuck from it and turned it true in place on the spindle.

I see what you mean, doh! Turned one belt around and will do when I get a chance

Do check that the threads in the chuck and those on th spindle are totally clean and don't have any dings on them . Also check the register collar on the shaft and the face of the register on the chuck for tiny dings If you have a reasonable face plate ,

...

In one of them he uses two morse taper mandrels an MT 3 in the hed stock & an MT 2 in the tailstock ( I think Ive put the correct sizes down ???) ending in a Jacobs taper to fit drill chucks on to check the trueness of the tail stock alignment after resetting . They are dirt cheap Chinese one's , fairly well finished from RG . My set of both sizes cost me about £9 inc p&p

Good idea about the mandrels - must get some

Also got a clock on the spindle today and the good news is that the run out is 0.01mm (0.0004") in the z axis, and about 0.005mm (0.0002") in the x axis

Also no clock movement when I grab the spindle and try to push it sideways and up/down, so it definitely looks like the spindle and bearings are fine

).

).