mike 109444

Member

- Messages

- 4,842

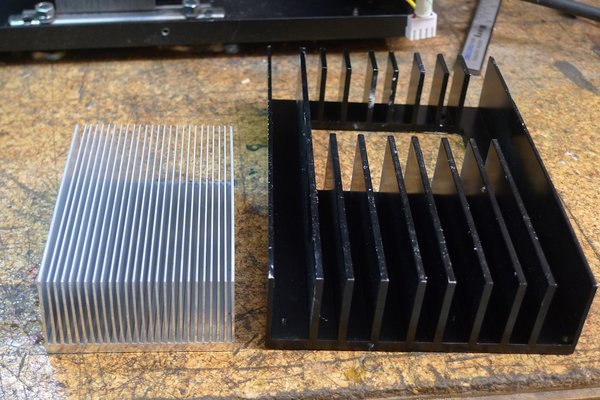

Ref the motor speed control. The motor in "normal" operation (connected to the feed unit/gearbox) will run at a very fast speed and the gearbox reduces this down a lot. Motor rpm = probable 1000, final output from gbox rpm = 20 rpm ! The DC geared motors on the equipment I work on have a 3000 rpm motor and three possible gearboxes of 48, 210 or 310 output with lots of torque. see pic

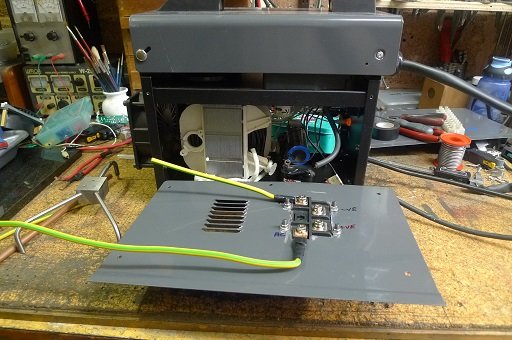

The MOV should be across the diode pack output. If you look at the pic in post 16 up and to the right of the top white circle is a light brown disc device, this is the MOV in that machine. Looking at the 2nd and 3rd diagrams in post 10, they are shown as an oblong device with a stepped line through it at an angle. Clarke seam to fit them before and after the diodes, go figure... . Note also if using the Clarke diagrams that they sometimes have a center tapped transformer (pro 90) and at other times a standard transformer (150 TE)

. Note also if using the Clarke diagrams that they sometimes have a center tapped transformer (pro 90) and at other times a standard transformer (150 TE)

With the inductor you should be able to experiment "externally to the welder with the number of turns using an old car jump start lead connected to the work return lead. Ref the wall wart. Fit the socket on the outside and run it's thin DC lead into welder until a better sized/shaped psu can be got.

The 1500cc capri had much the same engine as the MK1 1500 cortina (my first proper car!) and some corsairs had the same 1500cc as well as some early MK2's

The engine was an uprated version of the 1200cc which was an uprated version of the anglia 998 (Harry potter car) That is the basics , but purest would no doubt say there is more to is than that. ps the lotus cortina was also a 1500 block with lotus magic sprinkled over it

The MOV should be across the diode pack output. If you look at the pic in post 16 up and to the right of the top white circle is a light brown disc device, this is the MOV in that machine. Looking at the 2nd and 3rd diagrams in post 10, they are shown as an oblong device with a stepped line through it at an angle. Clarke seam to fit them before and after the diodes, go figure...

. Note also if using the Clarke diagrams that they sometimes have a center tapped transformer (pro 90) and at other times a standard transformer (150 TE)

. Note also if using the Clarke diagrams that they sometimes have a center tapped transformer (pro 90) and at other times a standard transformer (150 TE)With the inductor you should be able to experiment "externally to the welder with the number of turns using an old car jump start lead connected to the work return lead. Ref the wall wart. Fit the socket on the outside and run it's thin DC lead into welder until a better sized/shaped psu can be got.

The 1500cc capri had much the same engine as the MK1 1500 cortina (my first proper car!) and some corsairs had the same 1500cc as well as some early MK2's

The engine was an uprated version of the 1200cc which was an uprated version of the anglia 998 (Harry potter car) That is the basics , but purest would no doubt say there is more to is than that. ps the lotus cortina was also a 1500 block with lotus magic sprinkled over it

Yep fabric roof and so on. Dad towed me in it the couple of miles from his house to my then house with me steering sat on a milk create, that was scary. Think dad forgot it was not a modern car he was towing. Glad it was on a solid (scaffold pole) tow hitch. Think there was a sad tail of a sunbeam lotus on retro rides.

Yep fabric roof and so on. Dad towed me in it the couple of miles from his house to my then house with me steering sat on a milk create, that was scary. Think dad forgot it was not a modern car he was towing. Glad it was on a solid (scaffold pole) tow hitch. Think there was a sad tail of a sunbeam lotus on retro rides.

. Guy replied and stop off on his journey up the A38. He had a tow rope and even offered to tow the broken car back to Bristol but he was in a hurry so would have to get a move on with the towing. Well I'm glad it was not my car cos to follow a car being towed at 50 plus up and down the 15 or so miles back to Bristol along thee A38 past the airport if you know the road you would know what I mean.

. Guy replied and stop off on his journey up the A38. He had a tow rope and even offered to tow the broken car back to Bristol but he was in a hurry so would have to get a move on with the towing. Well I'm glad it was not my car cos to follow a car being towed at 50 plus up and down the 15 or so miles back to Bristol along thee A38 past the airport if you know the road you would know what I mean.