RWD3M

Forum Supporter

- Messages

- 3,899

- Location

- Wiltshire, UK

Let's recap.

The bottom ring (an oil control ring) has a locating lug in the piston groove. When the ring is in the groove, it can rotate quite freely. The problem I'm having is compressing the ring into the groove whilst keeping the locating pin aligned with the gap in the ring (or, keeping the gap in the ring aligned with the locating pin).

The ring compressor I have will compress all 4 rings with ease.

Neither end of the bore has a taper (or lead-in) so the rings need to be compressed fully before the piston can be inserted into the bore.

Fitting the piston from the top of the bore would give me better access but wouldn't help with the fundamental issue I have which is compressing the bottom ring whilst keeping the ring gap aligned with the locating pin.

It may well be that I need a different type of ring compressor but I'm not aware of one that will allow me to compress all the rings, keeping the bottom one aligned properly AND fit in the crankcase from below.

The bottom ring (an oil control ring) has a locating lug in the piston groove. When the ring is in the groove, it can rotate quite freely. The problem I'm having is compressing the ring into the groove whilst keeping the locating pin aligned with the gap in the ring (or, keeping the gap in the ring aligned with the locating pin).

The ring compressor I have will compress all 4 rings with ease.

Neither end of the bore has a taper (or lead-in) so the rings need to be compressed fully before the piston can be inserted into the bore.

That's correct Cobbler.If I understand you correctly, you can’t do that, you can’t feed in the pistons from the top, the big end won’t go through the bore, the piston won’t come up through enough to fit the bottom oil control ring.

Conceivably yes, but that wouldn't be my preferred method. The problem is I haven't found my preferred method yet!Could you remove the gudgeon pin , fit the oil control ring and insert the piston from the top of the block so the ring is into the bore then refit the Conrod/gudgeon pin before finally fitting the top rings? I once fitted new barrels and pistons to a mates VW with only basic hand tools using a similar method. I would be a bit concerned of catching the ring ends in the cut out section at the bottom of the bore although with carefully spacing the ring ends and using a decent ring compressor that compresses all of the rings it should be possible?

Fitting the piston from the top of the bore would give me better access but wouldn't help with the fundamental issue I have which is compressing the bottom ring whilst keeping the ring gap aligned with the locating pin.

It may well be that I need a different type of ring compressor but I'm not aware of one that will allow me to compress all the rings, keeping the bottom one aligned properly AND fit in the crankcase from below.

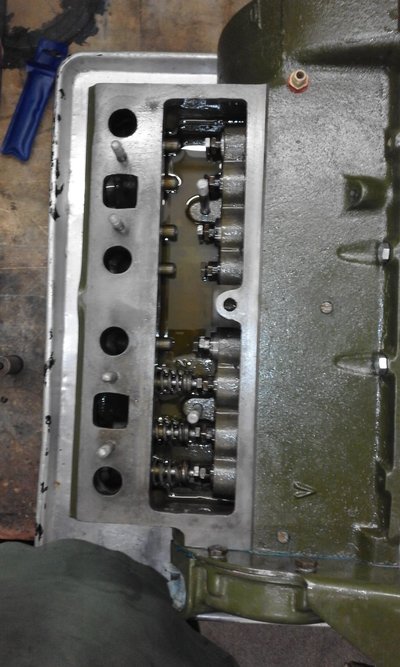

There's something very satisfying about putting an engine back together.

There's something very satisfying about putting an engine back together.