I was going to say give it a good clean and replace the other seals while you are at it, but you seem to have it all in hand.Five days delivery though, what am I gonna do without a lathe for a week!

I was going to say give it a good clean and replace the other seals while you are at it, but you seem to have it all in hand.Five days delivery though, what am I gonna do without a lathe for a week!

but I've I cut and annealed a tiny bit of 6mm copper to stop the threads getting mashed when I replace it.

Bit of hylomar. That's all I used on my Harrison. They will always loose some oil from the sealsAll back together and full of oil. Ran it up to full speed and it all seems fine, it gets a bit loud at higher speeds but everyone knows Colchesters are noisy.

View attachment 304515

View attachment 304514

Unfortunately, it does appear to still be leaking.

View attachment 304516

It's weeping out there, I was a bit suspicious when I took it apart as there's no gasket between the surfaces. Need to drain the oil and take everything back off to put one in, and I don't have any gasket material here anyway.

And mine .lolFlipping hell yours cracking on. Want to come do mine!

Hylomar is bullet proof.I'm always sceptical of liquid gasket type stuff, I trust a proper paper gasket more. I'll pop over to my dads and get some paper, and find something to drain this oil into so I don't waste any more.

I looked up the serial numbers too, A1411 I think means it was made in 1958, so it's 62 years old. I hope I look that good in 40 years.

I can try launching hylomar at a bulletBut are bullets Hylomar-proof?

I think the noise is actually the toothed belt which drives the spindle in the high speed range, throwing the spindle with the belts off is almost dead silent.Always found the Chipmaster to be much quieter than the geared head Colchester's, wonder where the noise is coming from.

If you run it in high speed, but with the feed/thread selector in thread mode, the gearbox doesn't turn so all the noise comes from the headstock, which isn't much noise at all, that's what I'd done without realising it yesterday. Today I put it into feed mode as you would to actually use it and if you crank the speed up there's quite a loud knocking which seems to be from the apron. Poking around a bit more, I noticed the feed shaft is a bit wobbly, putting an indicator on it I can rattle it about 20 thou, you can actually see a bit of a gap in the bushing in the gearbox body.

If you run it in high speed, but with the feed/thread selector in thread mode, the gearbox doesn't turn so all the noise comes from the headstock, which isn't much noise at all, that's what I'd done without realising it yesterday. Today I put it into feed mode as you would to actually use it and if you crank the speed up there's quite a loud knocking which seems to be from the apron. Poking around a bit more, I noticed the feed shaft is a bit wobbly, putting an indicator on it I can rattle it about 20 thou, you can actually see a bit of a gap in the bushing in the gearbox body.

Mines like that. You'll probably find the feed shaft is bent and that's what's worn the bushesI've changed my mind about the noise again.If you run it in high speed, but with the feed/thread selector in thread mode, the gearbox doesn't turn so all the noise comes from the headstock, which isn't much noise at all, that's what I'd done without realising it yesterday. Today I put it into feed mode as you would to actually use it and if you crank the speed up there's quite a loud knocking which seems to be from the apron. Poking around a bit more, I noticed the feed shaft is a bit wobbly, putting an indicator on it I can rattle it about 20 thou, you can actually see a bit of a gap in the bushing in the gearbox body.

View attachment 332320

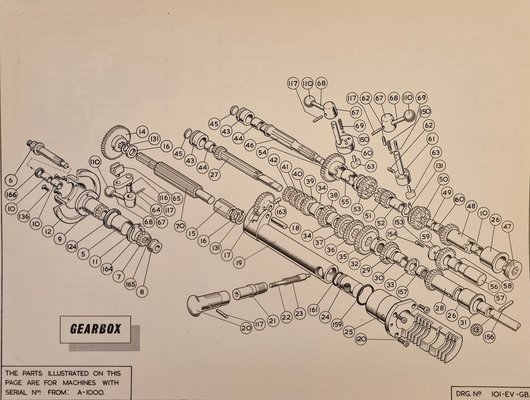

It looks like quite a big job to get in there and press it out, but quite a simple part to make, it might even be standard enough that I can just order a flanged oilite bush and press it straight in. Part 26, in the bottom right hand side.

View attachment 332328

Worthwhile job mate and it is daunting but it's not actually too bad. My feedsvrew is definitely a bit bent as I hear it knocking when the carriage is in certain positions.It being bent would explain it knocking in the apron. It looks like there's just one grub screw to loosen and the shaft will pull right out without having to pull anything apart, I can check it against a straight edge and bonk it true. Having said that, it would be good to dismantle and clean the apron actually, the whole thing's filthy inside. I'll have a look tomorrow.