You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Plasma table

- Thread starter Hood

- Start date

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

I am not promising myself, I am just hoping. All depends on when the new Cat arrives if it is late then unless it is very late I may well be workingVery smart.

Time over Christmas im promising myself that one aswell

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

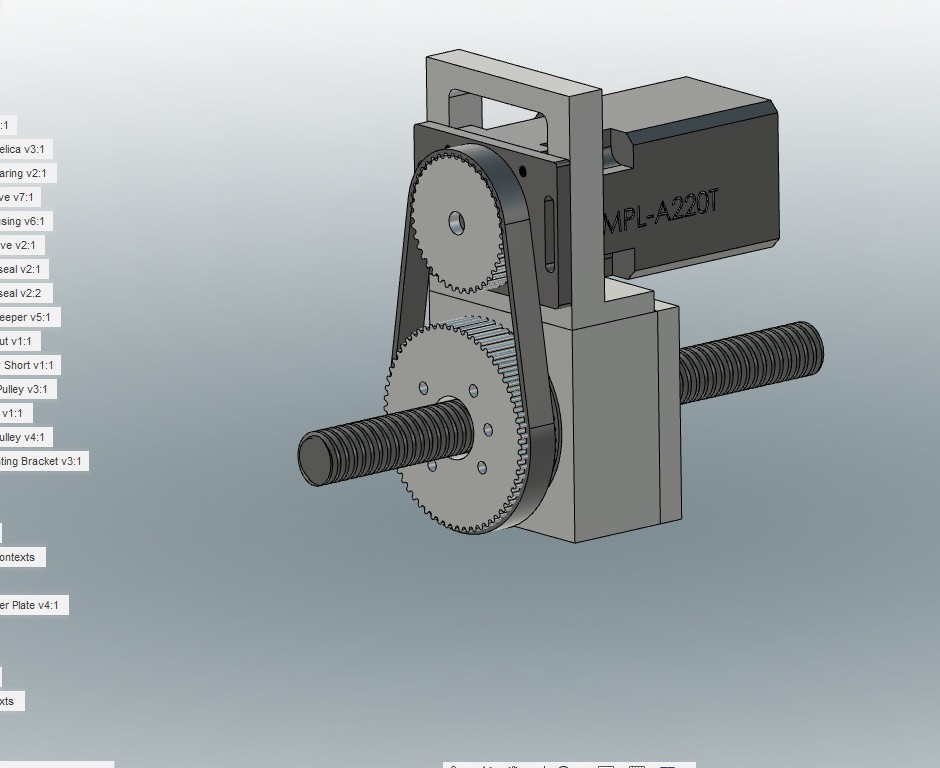

The ballscrew arrived yesterday, still waiting on seals and locking nut. I could have made a locking nut easily enough but they are so cheap it isn't worth me doing it especially as I am already paying postage on the seals.

I ordered a 500mm long length of 4" square Aluminium instead of the flat bar. It should be here today but not sure if I will get a chance to make a start on it.

Have the design more or less finalised, it should make for a nice compact unit.

I ordered a 500mm long length of 4" square Aluminium instead of the flat bar. It should be here today but not sure if I will get a chance to make a start on it.

Have the design more or less finalised, it should make for a nice compact unit.

mtt.tr

Member

- Messages

- 8,436

- Location

- Essex/Suffolk border

The ballscrew arrived yesterday, still waiting on seals and locking nut. I could have made a locking nut easily enough but they are so cheap it isn't worth me doing it especially as I am already paying postage on the seals.

I ordered a 500mm long length of 4" square Aluminium instead of the flat bar. It should be here today but not sure if I will get a chance to make a start on it.

Have the design more or less finalised, it should make for a nice compact unit.

View attachment 258001

Thats a very neat solution.

Jay1st

AdeptusMechanicus wanna be.

- Messages

- 298

- Location

- South West FRANCE

That looks good and i like your solution.

At work we finished a machine with a 1500mm long ballscrew (the very very expensive type) and during fast moves we get some vibrations with harmonics, had to lower the Kp value in the driver and the acceleration timing as well, but the motor turns the ballcrew not the nut. Even though everything is perfectly aligned and the ballscrew has preloaded + matched bearings it keeps making some nasty noise.

At work we finished a machine with a 1500mm long ballscrew (the very very expensive type) and during fast moves we get some vibrations with harmonics, had to lower the Kp value in the driver and the acceleration timing as well, but the motor turns the ballcrew not the nut. Even though everything is perfectly aligned and the ballscrew has preloaded + matched bearings it keeps making some nasty noise.

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

Yes that was my worry about having the screw rotating. It is 25mm dia and about 1800mm long and will be doing 4000rpm at rapids so I thought the screw under tension and the nut rotating would be better, hopefully it willThat looks good and i like your solution.

At work we finished a machine with a 1500mm long ballscrew (the very very expensive type) and during fast moves we get some vibrations with harmonics, had to lower the Kp value in the driver and the acceleration timing as well, but the motor turns the ballcrew not the nut. Even though everything is perfectly aligned and the ballscrew has preloaded + matched bearings it keeps making some nasty noise.

henry Kadzielski

Member

- Messages

- 1,217

- Location

- Australia Wollongong

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

good morning @Hood, why not a rack for that axis. Both my X and Y axis are rack, the only thing that I may have done different (but I already had the parts) would have gone to a helical rack. Both quieter and stronger, down side cost

I have helical rack on it at the moment, very nice high precision rack but I don't have enough for the redesigned layout.

Not keen on straight teeth rack as only one tooth engaged at a time and to go helical is big money so ballscrew is the the best way I think.

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

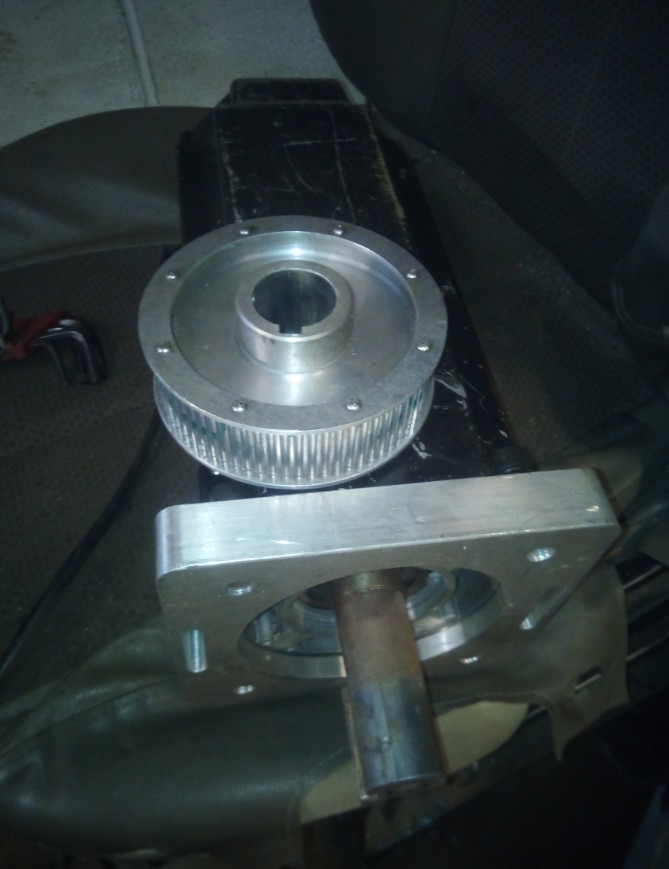

Ok, bit of a redesign required. Nothing major it is just I remembered about a speed increaser I had made for the Chirons spindle which ended up being too noisy for my liking as the spindle pulley was doing over 7000rpm.

Anyway hauled it out and the pulley on the motor will do and possibly the belt, so that should save me £40-£50 The pulley on the spindle shaft is only a 44 tooth and I would have preferred a 48 but we will see, if the belt will fit in then I will likely just use it.

The pulley on the spindle shaft is only a 44 tooth and I would have preferred a 48 but we will see, if the belt will fit in then I will likely just use it.

Pics of the bracket I had made with belt and pulley and spare spindle motor and pulley.

Anyway hauled it out and the pulley on the motor will do and possibly the belt, so that should save me £40-£50

The pulley on the spindle shaft is only a 44 tooth and I would have preferred a 48 but we will see, if the belt will fit in then I will likely just use it.

The pulley on the spindle shaft is only a 44 tooth and I would have preferred a 48 but we will see, if the belt will fit in then I will likely just use it.Pics of the bracket I had made with belt and pulley and spare spindle motor and pulley.

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

The Aluminium arrived today.

Chopped a couple of bits off in the bandsaw.

Then milled them out on the Chiron and ended up with these.

the other side

The bearings are a nice slide fit

Hopefully the seals and the locknut will turn up tomorrow and with a bit of luck I will get a chance to make up the ball nut sleeve.

Chopped a couple of bits off in the bandsaw.

Then milled them out on the Chiron and ended up with these.

the other side

The bearings are a nice slide fit

Hopefully the seals and the locknut will turn up tomorrow and with a bit of luck I will get a chance to make up the ball nut sleeve.

henry Kadzielski

Member

- Messages

- 1,217

- Location

- Australia Wollongong

I would love to have your knowledge and expertise. It seems that I am just floundering in comparison to you, where I really fall short is in cad stuff. Am hoping to correct that in the future at some stage

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

The seals and locknut arrived today so this evening I made up the sleeve that holds the ballnut and goes through the bearings.

Pictures are a bit grainy I am afraid.

Test fitted but I still have to bore and tap the holes on the flange for the ball nut and pulley fixing to.

I also still have the packer sleeve to make, it goes between the bearings inner races and the locknut and it also what the seal will run on.

Pictures are a bit grainy I am afraid.

Test fitted but I still have to bore and tap the holes on the flange for the ball nut and pulley fixing to.

I also still have the packer sleeve to make, it goes between the bearings inner races and the locknut and it also what the seal will run on.

addjunkie

Member

- Messages

- 12,904

- Location

- Northumberland. Reet oot in the sticks

I am not promising myself, I am just hoping. All depends on when the new Cat arrives if it is late then unless it is very late I may well be working

Is that why there is a yellow one forsale up your way?

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

No, that is one that is owned by a guy that is also a farmer. He is putting more time in at the farm now due to his granddad getting on in age so he is having to spend less time at sea.Is that why there is a yellow one forsale up your way?

You and me both.I would love to have your knowledge and expertise. It seems that I am just floundering in comparison to you, where I really fall short is in cad stuff. Am hoping to correct that in the future at some stage

Sadly I start with great intentions and eventually read threads like this and feel why bother.

I know it's a bad way to think but I can't help it as I get older.

Hopefully I will get over it and just keep learning but I am finding things get harder and harder to grasp and find money for.

slim_boy_fat

Member

- Messages

- 29,540

- Location

- Scottish Highlands

Then got the spacer made up.

Did you make those chuck jaws yourself?

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

I think I did, I have made lots of soft jaws up for different chucks but can't be 100% sure if I made these particular ones or not.Did you make those chuck jaws yourself?

That chuck has tenons on the lower jaws so making soft tops for them is easy, the CNC lathe has serrations so it is a bit more involved and I usually wait until Cutwel have an offer on the soft jaws for the CNC chuck as I get them for about £30 the set.