You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Posh woodworking vice

- Thread starter brewdexta

- Start date

Dieselman 63

Forklift Certified

- Messages

- 5,681

- Location

- Wellington, New Zealand

Bench is coming along nicely, I’d be afraid of using it in case it gets marked or dinked

That’d age to become patina, history and character

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,125

- Location

- NE London - UK

I'm rapidly running out of corners

You need to make some more, then

brewdexta

The biggest tool in the box

- Messages

- 5,601

- Location

- UK

You need to make some more, then

Looks like I will have to, looks like I may have 3 more machines coming soon

I can see some machine rationalisation coming up soon......

slim_boy_fat

Forum Supporter

- Messages

- 29,540

- Location

- Scottish Highlands

looks like I may have 3 more machines coming soon

Repeat after me..."Must stop buying machines, must stop buying machines, must stop buying machines..."

addjunkie

Forum Supporter

- Messages

- 12,422

- Location

- Northumberland. Reet oot in the sticks

That needs re wordingRepeat after me..."Must stop buying machines, must stop buying machines, must stop buying machines..."

Must build bigger shed!

brewdexta

The biggest tool in the box

- Messages

- 5,601

- Location

- UK

Next job was to route a slot under the front half of the bench for the sliding deadman.

Then plane up the sides to remove the saw marks. You can see them here.

A big Clifton No.6, lovely and heavy, nice thick plane iron.

equals lovely whispy shavings, well that and a good sharpening system

Then trim the tops to length, not easy as they are so big. I used the wind up table on the radial arm drill to level it up.

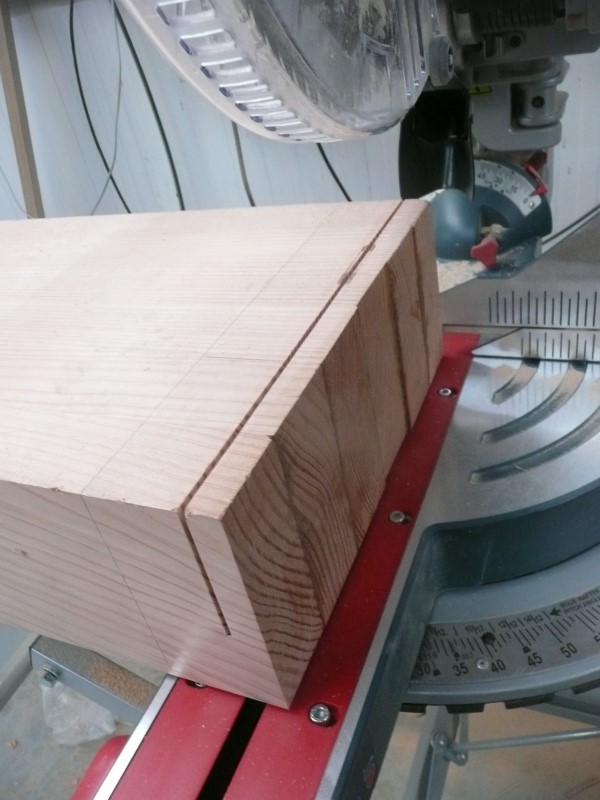

The mitre saw is a big-un but couldn't cut this in one go.

so finished it off with a Japanese style pull saw.

Tops back on and sand the ends up

Then glue and clamp the ledges for the shelf underneath.

Then fit the planks to sit on them, its a bit dusty.

continued, run out of photo space in this post......

Then plane up the sides to remove the saw marks. You can see them here.

A big Clifton No.6, lovely and heavy, nice thick plane iron.

equals lovely whispy shavings, well that and a good sharpening system

Then trim the tops to length, not easy as they are so big. I used the wind up table on the radial arm drill to level it up.

The mitre saw is a big-un but couldn't cut this in one go.

so finished it off with a Japanese style pull saw.

Tops back on and sand the ends up

Then glue and clamp the ledges for the shelf underneath.

Then fit the planks to sit on them, its a bit dusty.

continued, run out of photo space in this post......

brewdexta

The biggest tool in the box

- Messages

- 5,601

- Location

- UK

I also cut the bottom slider for the sliding deadman, no pictures. The started to fit the tail vice, first mark it out.

Then route it out with a Dewalt router on a Bosch router base on a Mafell track. I modified the base and router to fit, and Mafell track is the same as Bosch, I believe they make it for Bosch.

One of the clamps is also the stop for the router.

Trench for the vice completed

The start on the cover, I resawed a bit of walnut on the bandsaw then thicknessed it down to 7.5mm, trimmed it to size then routed a slot. The slot needed widening a tad.

Fitted nicely

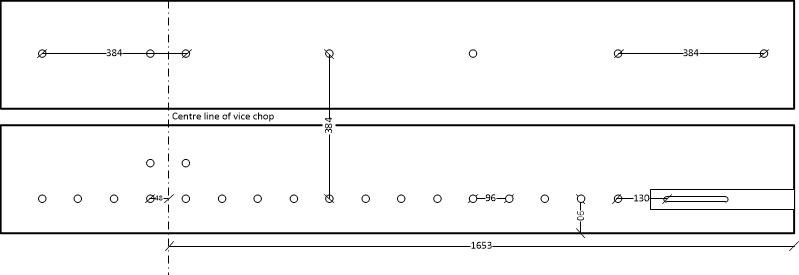

Then started on the holes, I'm using the Parf system spacing as follows, so most spacing are multiples of 96mm. So distance between dog holes on the front and rear bench is 4 "parf" distances and as there is no tail vice on the rear bench, the rear bench has a row 4 parf distances apart.

The front bench row has to be less than 150mm, the throw of the vice, so a full rack of holes every 96mm is drilled, and a couple of extra behind the front leg vice chop.

I've just drilled the 3mm holes for the guide pins on the front bench at the moment, the rear bench will be done once I have screwed the tops down in case there is any movement.

All for now.

Cheers

Andy

Then route it out with a Dewalt router on a Bosch router base on a Mafell track. I modified the base and router to fit, and Mafell track is the same as Bosch, I believe they make it for Bosch.

One of the clamps is also the stop for the router.

Trench for the vice completed

The start on the cover, I resawed a bit of walnut on the bandsaw then thicknessed it down to 7.5mm, trimmed it to size then routed a slot. The slot needed widening a tad.

Fitted nicely

Then started on the holes, I'm using the Parf system spacing as follows, so most spacing are multiples of 96mm. So distance between dog holes on the front and rear bench is 4 "parf" distances and as there is no tail vice on the rear bench, the rear bench has a row 4 parf distances apart.

The front bench row has to be less than 150mm, the throw of the vice, so a full rack of holes every 96mm is drilled, and a couple of extra behind the front leg vice chop.

I've just drilled the 3mm holes for the guide pins on the front bench at the moment, the rear bench will be done once I have screwed the tops down in case there is any movement.

All for now.

Cheers

Andy

Dieselman 63

Forklift Certified

- Messages

- 5,681

- Location

- Wellington, New Zealand

Beware of uneven floors!

Beware of oily machinery!

Beware of men pottering about!

Is that you in shot?

brewdexta

The biggest tool in the box

- Messages

- 5,601

- Location

- UK

If that handle spun around and caught you in the nads you would be singing castrato

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,125

- Location

- NE London - UK

Is that you in shot?

No, I'm considerably younger than him (well, 5 years of so

)

)brewdexta

The biggest tool in the box

- Messages

- 5,601

- Location

- UK

I did it a bit more early this morning and this evening. First I finished fitting the tail vice.

Then drilled the dog holes with the parf system. I had to put a few more in along the back as the jig needs the holes closely spaced for alignment.

Not much more to do, vice chop and sliding deadman to finish then a bit of oil to finish.

Then drilled the dog holes with the parf system. I had to put a few more in along the back as the jig needs the holes closely spaced for alignment.

Not much more to do, vice chop and sliding deadman to finish then a bit of oil to finish.

Phillip Goodison

New Member

- Messages

- 26

- Location

- Norfolk, England

Absolutely stunning!

addjunkie

Forum Supporter

- Messages

- 12,422

- Location

- Northumberland. Reet oot in the sticks

To nice to actually use, it might get markedLooks really really nice.

brewdexta

The biggest tool in the box

- Messages

- 5,601

- Location

- UK

I got a good day in today, and did the fiddly bits that are hard to put right if you get them wrong. I cut the bottom of the sliding deadman first, this is V shape that slides along an inverted V shaped length of wood underneath the bench.

Then rough out the shape of the sliding deadman on the bandsaw

Same with the vice chop, I used a posh new hand stitched Liogier rasp to take away most of the material in the radius corners then finished off on my crap bobbin sander with the chinesium table that isn't anywhere near flat on the front side, so used the back. That will be going very soon, last piece of useless junk I buy, old gear or quality new from now on.

Looks ok, just need the vice height trimming and a bevel putting on it and a few holes in the sliding deadman.

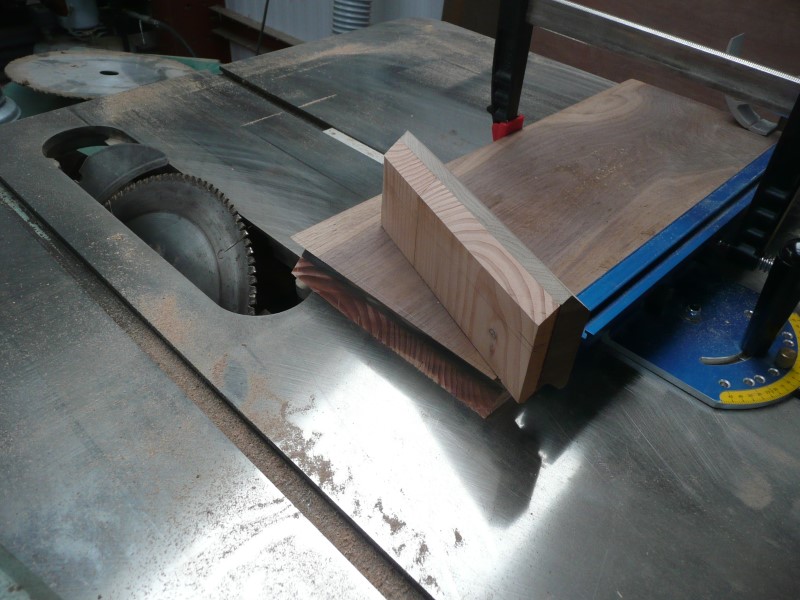

So cut the vice chop to height then cut the bevel, almost, saw blade not quite big enough. There are other ways of doing this, but I decided this was the safest due to the size and weight.

I cut the remaining wood with a Japanese pull saw put it on the bench in the tail vice and used a low angle block plane to cut it flush.

Then drill the deadman's holes.

And assemble it. I gave the vice chop and the leg it attaches to a good sand and installed the criss-cross pins all the way through, the holes will be covered with walnut dowel.

So all together, needs a good sanding then finishing with oil. I will probably use Osmo Polyx hardwax oil as I like the finish, and if you need to repair a bit its easy to sand down and blend in, not that I intend to overly mollycoddle the bench, but may not reassemble the dexta engine on it Looks like it's snowing, I must give the camera lens a brush.

Looks like it's snowing, I must give the camera lens a brush.

I'm liking the bronze handwheel more and more, the vice moves nicely in and out, and if you spin the wheel it keeps going a bit longer, even though the vice screw is currently completely dry.

It will look different again once the bench is oiled. I still have a bit of woodwork to do, there is a tool tray that fits in the gap in the bench top. If you move this to one side it sticks up about 10mm to act as a planing stop. That may take a bit longer as I promised to start on the kitchen tomorrow.

Cheers

Andy

Then rough out the shape of the sliding deadman on the bandsaw

Same with the vice chop, I used a posh new hand stitched Liogier rasp to take away most of the material in the radius corners then finished off on my crap bobbin sander with the chinesium table that isn't anywhere near flat on the front side, so used the back. That will be going very soon, last piece of useless junk I buy, old gear or quality new from now on.

Looks ok, just need the vice height trimming and a bevel putting on it and a few holes in the sliding deadman.

So cut the vice chop to height then cut the bevel, almost, saw blade not quite big enough. There are other ways of doing this, but I decided this was the safest due to the size and weight.

I cut the remaining wood with a Japanese pull saw put it on the bench in the tail vice and used a low angle block plane to cut it flush.

Then drill the deadman's holes.

And assemble it. I gave the vice chop and the leg it attaches to a good sand and installed the criss-cross pins all the way through, the holes will be covered with walnut dowel.

So all together, needs a good sanding then finishing with oil. I will probably use Osmo Polyx hardwax oil as I like the finish, and if you need to repair a bit its easy to sand down and blend in, not that I intend to overly mollycoddle the bench, but may not reassemble the dexta engine on it

Looks like it's snowing, I must give the camera lens a brush.

Looks like it's snowing, I must give the camera lens a brush.I'm liking the bronze handwheel more and more, the vice moves nicely in and out, and if you spin the wheel it keeps going a bit longer, even though the vice screw is currently completely dry.

It will look different again once the bench is oiled. I still have a bit of woodwork to do, there is a tool tray that fits in the gap in the bench top. If you move this to one side it sticks up about 10mm to act as a planing stop. That may take a bit longer as I promised to start on the kitchen tomorrow.

Cheers

Andy

slim_boy_fat

Forum Supporter

- Messages

- 29,540

- Location

- Scottish Highlands

Beautiful work!!

Parm

Respect The Sound System

- Messages

- 17,862

- Location

- Towcester

I got a good day in today, and did the fiddly bits that are hard to put right if you get them wrong. I cut the bottom of the sliding deadman first, this is V shape that slides along an inverted V shaped length of wood underneath the bench.

View attachment 168044

Then rough out the shape of the sliding deadman on the bandsaw

View attachment 168046

Same with the vice chop, I used a posh new hand stitched Liogier rasp to take away most of the material in the radius corners then finished off on my crap bobbin sander with the chinesium table that isn't anywhere near flat on the front side, so used the back. That will be going very soon, last piece of useless junk I buy, old gear or quality new from now on.

View attachment 168047

Looks ok, just need the vice height trimming and a bevel putting on it and a few holes in the sliding deadman.

View attachment 168048

So cut the vice chop to height then cut the bevel, almost, saw blade not quite big enough. There are other ways of doing this, but I decided this was the safest due to the size and weight.

View attachment 168049

I cut the remaining wood with a Japanese pull saw put it on the bench in the tail vice and used a low angle block plane to cut it flush.

View attachment 168050

Then drill the deadman's holes.

View attachment 168051

And assemble it. I gave the vice chop and the leg it attaches to a good sand and installed the criss-cross pins all the way through, the holes will be covered with walnut dowel.

View attachment 168052

So all together, needs a good sanding then finishing with oil. I will probably use Osmo Polyx hardwax oil as I like the finish, and if you need to repair a bit its easy to sand down and blend in, not that I intend to overly mollycoddle the bench, but may not reassemble the dexta engine on itLooks like it's snowing, I must give the camera lens a brush.

View attachment 168053

I'm liking the bronze handwheel more and more, the vice moves nicely in and out, and if you spin the wheel it keeps going a bit longer, even though the vice screw is currently completely dry.

View attachment 168054

It will look different again once the bench is oiled. I still have a bit of woodwork to do, there is a tool tray that fits in the gap in the bench top. If you move this to one side it sticks up about 10mm to act as a planing stop. That may take a bit longer as I promised to start on the kitchen tomorrow.

Cheers

Andy

Looks fantastic, but educate me please. What’s the function / purpose of the sliding deadman?