RaceDiagnostics

Forum Supporter

- Messages

- 3,186

If yesterday was slow progress, today was a snails pace.

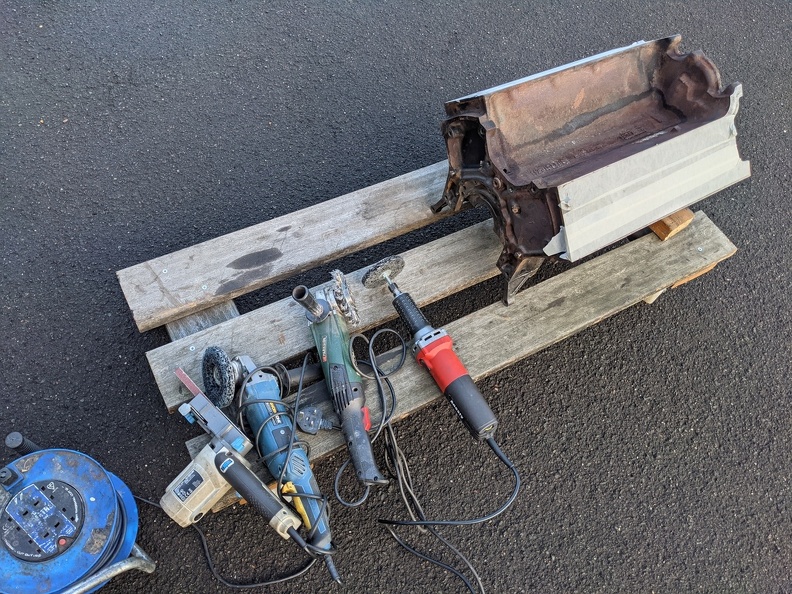

I tried welding on another couple of nuts but made little progress getting the sheared off bolt out, so decided to try to drill it out.

First I cleaned up the end of the bolt to try to get the drill to find the centre.

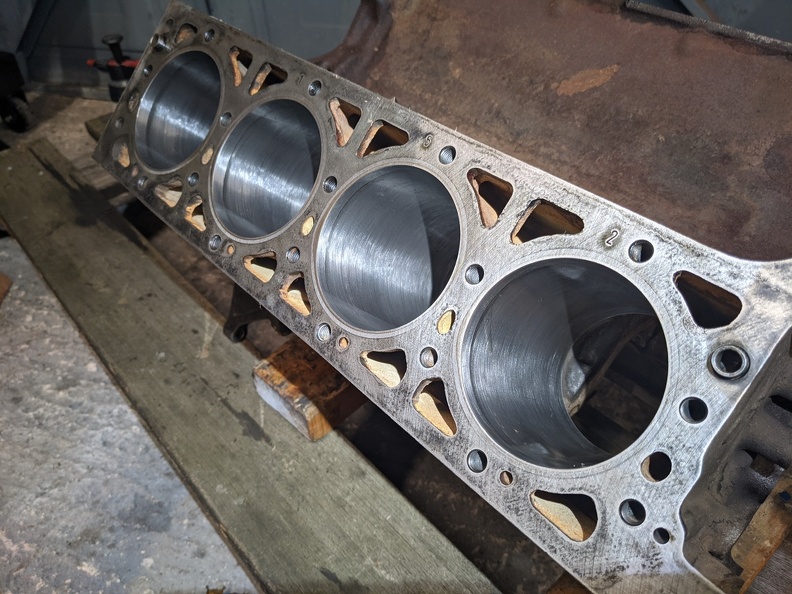

The head wedged to try to get the bolt vertical, almost impossible without a mill and clamps.

Drilled out, a bit off-centre.

Cleaning up the threads.

Trial fit! I will use a 5mm longer bolt to ensure I get down into good threads as the hole is pretty deep.

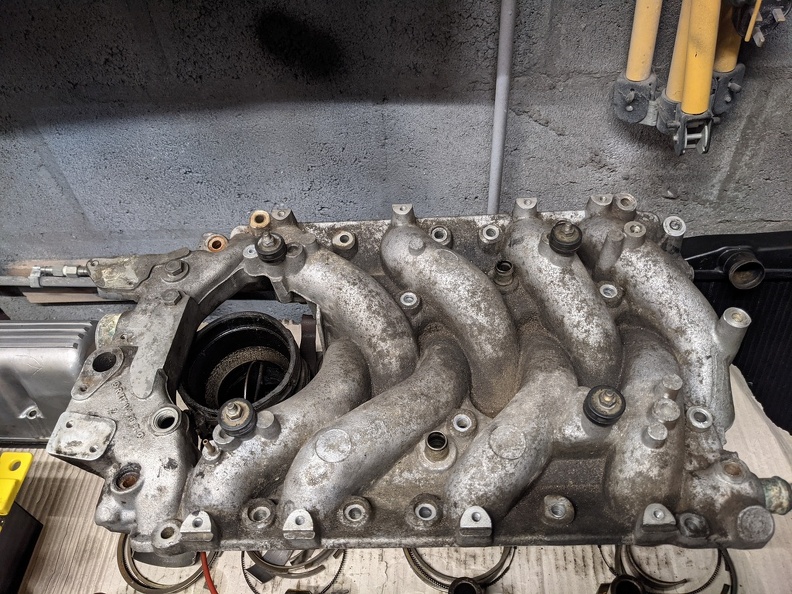

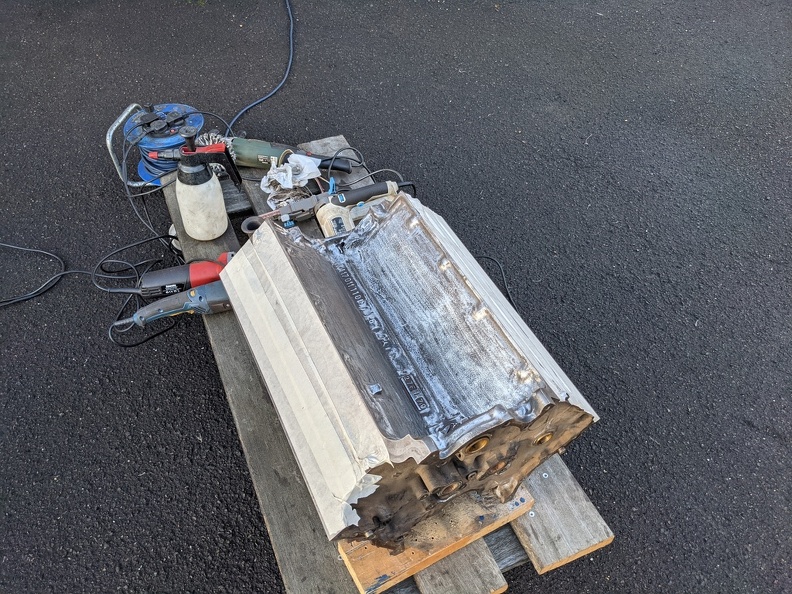

Next I split the intake manifold and had a look at the remainder of the bolt in it, I gave the end of the sheared bolt a few hits with a hammer (it's been soaked in releasing fluid for at least a week now), there was zero movement. I will take it to the engine shop to get it drilled out on a mill.

Finally today I cleaned the oven cleaner off of the valves, it had an affect, but there was still bits of what looked like cement left, however it cleaned off well on the lathe using some emery paper.

Only half of the valves had been treated with oven cleaner, these cleaned up relatively easily on the lathe, the others took much longer to clean. This is one of the untreated valves before and after.

Note the valve stems were protected with a rolled up section of coke can.

I tried welding on another couple of nuts but made little progress getting the sheared off bolt out, so decided to try to drill it out.

First I cleaned up the end of the bolt to try to get the drill to find the centre.

The head wedged to try to get the bolt vertical, almost impossible without a mill and clamps.

Drilled out, a bit off-centre.

Cleaning up the threads.

Trial fit! I will use a 5mm longer bolt to ensure I get down into good threads as the hole is pretty deep.

Next I split the intake manifold and had a look at the remainder of the bolt in it, I gave the end of the sheared bolt a few hits with a hammer (it's been soaked in releasing fluid for at least a week now), there was zero movement. I will take it to the engine shop to get it drilled out on a mill.

Finally today I cleaned the oven cleaner off of the valves, it had an affect, but there was still bits of what looked like cement left, however it cleaned off well on the lathe using some emery paper.

Only half of the valves had been treated with oven cleaner, these cleaned up relatively easily on the lathe, the others took much longer to clean. This is one of the untreated valves before and after.

Note the valve stems were protected with a rolled up section of coke can.