- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rexvalter VF-118 lathe (was: old Myford Ml7)

- Thread starter DennisCA

- Start date

DennisCA

Member

- Messages

- 2,050

- Location

- Finland

Yeah I went out and tested it and that's that the thing does, so I do have a way to lock it! That's one problem solved. Also the J&S holders you were referring to, are you recommending those over what I linked? I can't find any J&S tool holders googling. I've been trying to find a tool bit holder that was made for metric HSS bits, like 6x6, 8x8 or 10x10mm square.

https://www.chronos.ltd.uk/acatalog..._Sets___Loose_HSS_Toolsteel_Toolbits__66.html

Set of 3 Traditional Lathe Toolbit Holders 22.5 mm H Shank (Ref: ECLSET)

You'll find 1/4", 5/16", 3/8" is probably still standard, I use 1/4" in the tool holders as I was given some years ago, for the 8mm and larger tool steel just clamped in the tool post.

Set of 3 Traditional Lathe Toolbit Holders 22.5 mm H Shank (Ref: ECLSET)

You'll find 1/4", 5/16", 3/8" is probably still standard, I use 1/4" in the tool holders as I was given some years ago, for the 8mm and larger tool steel just clamped in the tool post.

DennisCA

Member

- Messages

- 2,050

- Location

- Finland

I did find in the parts drawer that I had one so I guess that's enough for me to test with.

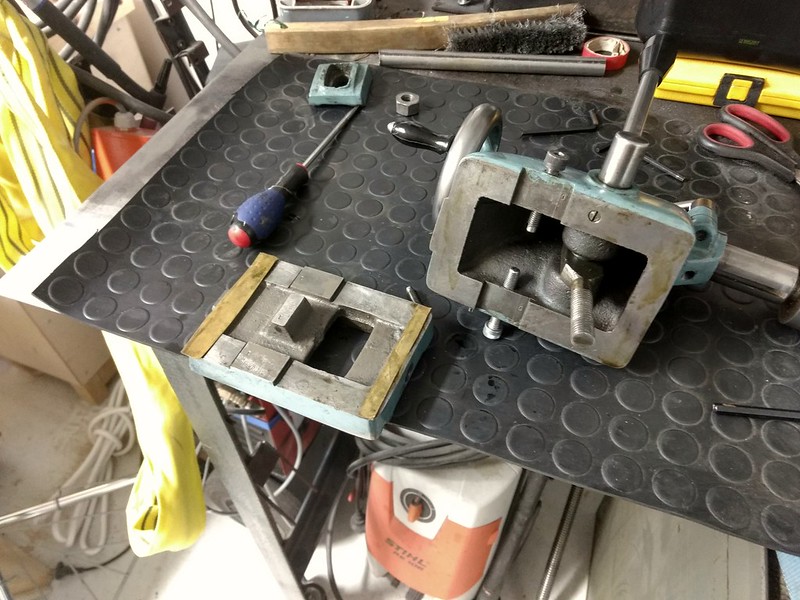

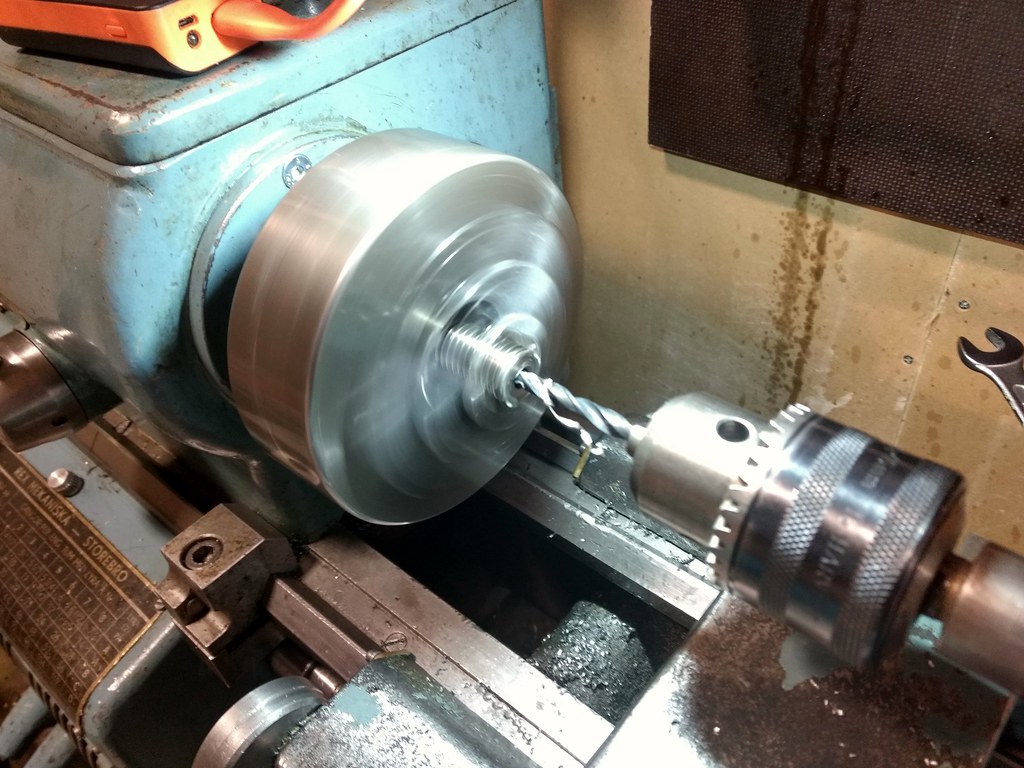

Anyway I did some lathe work last night and today, I am lacking one of the 4 threaded rods that move the jaws of the independent 4-jaw chuck in and out.

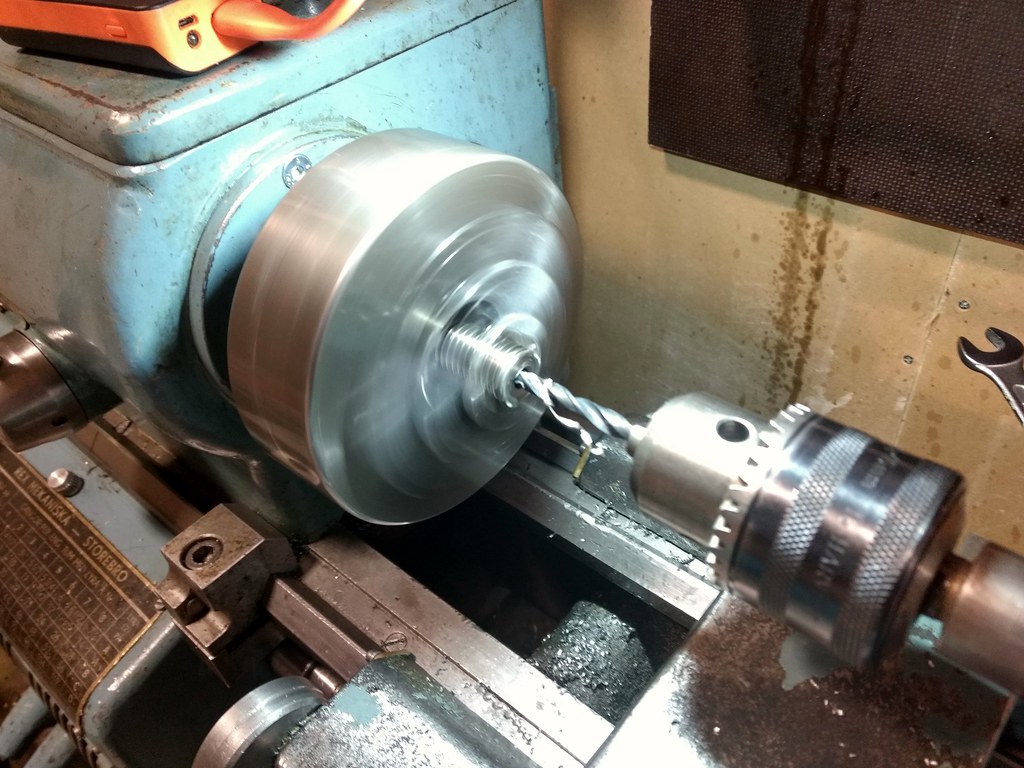

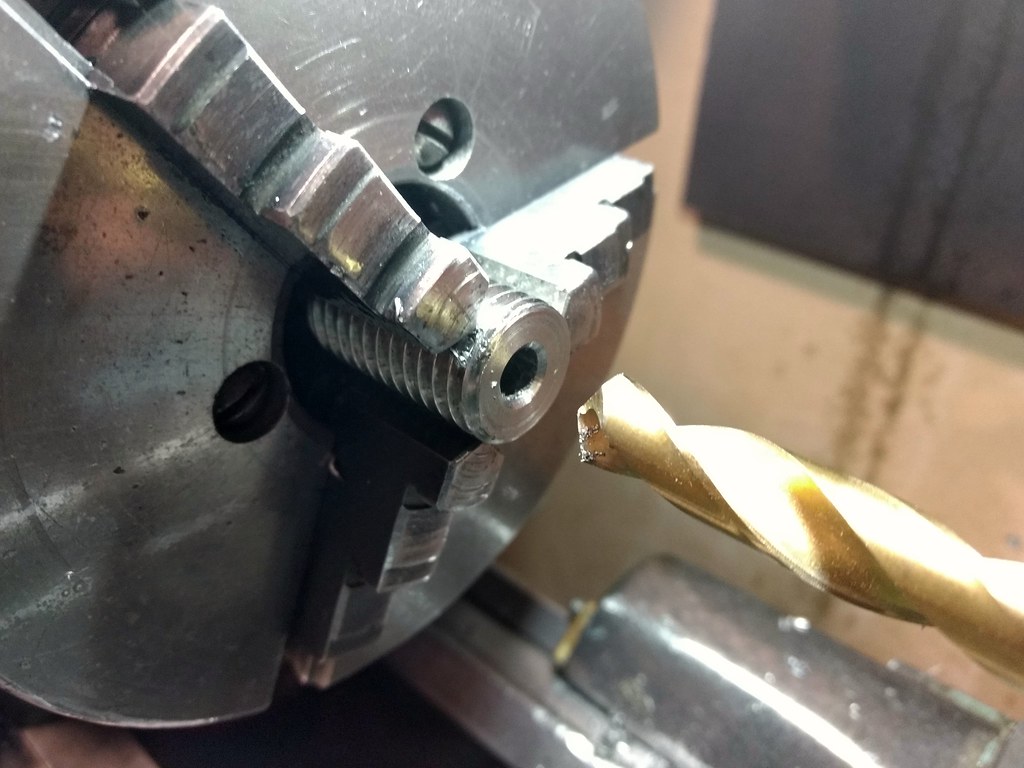

I bought the threaded rod because I was lacking any suitable material to turn from. Parted off a piece last night and was gonna drill it but it just wasn't working very well. Turns out the tailstock was sitting lower than the center line of the lathe. I don't have a MT3 dead center I can put in my spindle to get the true center so I turned a cone from a small piece of steel.

Anyway I took apart the tailstock and it had three shims, I tried swapping them around since I figured I might have put them in the wrong way when I last had it apart and that got it closer. But I got the closest when I removed one of the three shims.

As close as I could get it by eye anyway, the live center is a bit worn.

After that I tried drilling again and it worked much better this time.

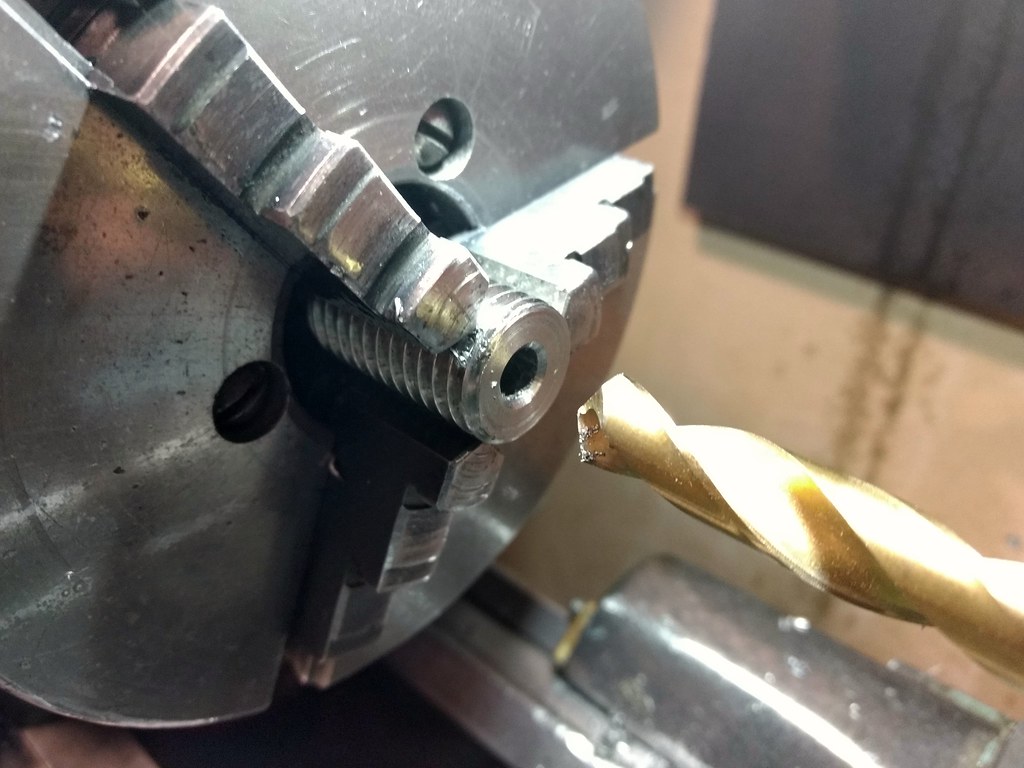

Chamfering

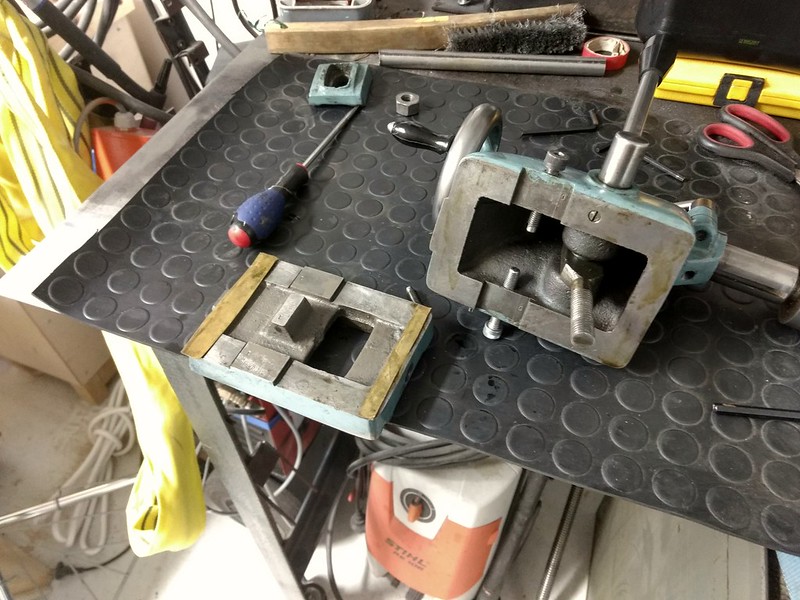

One of the originals and the new part:

Now I have to turn that round hole square, sounds like lots of filing.... A broach would be nice but I don't got any. I hear there are things called rotary broaches for lathes too that can make square or hex holes or whatever. But for me it's probably the file...

Anyway I did some lathe work last night and today, I am lacking one of the 4 threaded rods that move the jaws of the independent 4-jaw chuck in and out.

I bought the threaded rod because I was lacking any suitable material to turn from. Parted off a piece last night and was gonna drill it but it just wasn't working very well. Turns out the tailstock was sitting lower than the center line of the lathe. I don't have a MT3 dead center I can put in my spindle to get the true center so I turned a cone from a small piece of steel.

Anyway I took apart the tailstock and it had three shims, I tried swapping them around since I figured I might have put them in the wrong way when I last had it apart and that got it closer. But I got the closest when I removed one of the three shims.

As close as I could get it by eye anyway, the live center is a bit worn.

After that I tried drilling again and it worked much better this time.

Chamfering

One of the originals and the new part:

Now I have to turn that round hole square, sounds like lots of filing.... A broach would be nice but I don't got any. I hear there are things called rotary broaches for lathes too that can make square or hex holes or whatever. But for me it's probably the file...

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,957

- Location

- NE London - UK

Dennis, If you've only fitted one shim it's probable that the tailstock is now out of parallel with the spindle axis. It may not cause you much trouble when drilling, although the drill is being side loaded and will flex, which may casue a breakage but, if you ever need to ream something it will be an issue.

DennisCA

Member

- Messages

- 2,050

- Location

- Finland

I considered it but am unsure how to properly check the parallelism, I removed one 0.02mm shim. Perhaps some kind of perfectly ground shaft with a #2 morse taper to fit into the tail stock. Then run a dial indicator along it's length.

EDIT: That's a 0 too much, 0.2mm shim.

EDIT: That's a 0 too much, 0.2mm shim.

Pete.

Member

- Messages

- 14,998

- Location

- Kent, UK

The proper way to align the tailstock is by the 'two collar test'. Stick a piece of whatever metal in the chuck and turn it to the exact diameter of the tailstock ram (measure with a micrometer). Now wind the ram out and push it up close to your turned collar. Put a dial gauge on the saddle lined up where your cutting tool would touch and sweep across from one to the other, adjust the tailstock until the dial reads the same on both.

You can also check the vertical alignment using the same method but it doesn't affect turning a true part nearly as much as sideways alignment.

You can also check the vertical alignment using the same method but it doesn't affect turning a true part nearly as much as sideways alignment.

Pete.

Member

- Messages

- 14,998

- Location

- Kent, UK

Because I wasn't addressing that as an issue, just saying how to align the ram to the spindle sideways.

Nod in a tailstock ram is rarely enough to cause problems for everyday turning. It could be 10 thou low or more and not affect the diameter enough to measure. Sideways is a different matter - any sideways misalignment is doubled in a part turned between centres so the effect is significant.

Nod in a tailstock ram is rarely enough to cause problems for everyday turning. It could be 10 thou low or more and not affect the diameter enough to measure. Sideways is a different matter - any sideways misalignment is doubled in a part turned between centres so the effect is significant.

DennisCA

Member

- Messages

- 2,050

- Location

- Finland

I tested the ram as you call it, I thought it was called the quill, the part that goes in and out of the tailstock. I used a dial indicator on the top and zeroed it with the ram fully retracted. Then I retracted the tailstock and extended the ram fully (but not so far so it left the threads) and moved the ram into position and measured, with the tailstock locked in both positions ofcourse. Total runout was 0.02mm which seems OK to me.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,957

- Location

- NE London - UK

the quill

Correct

Ton-up

Member

- Messages

- 2,336

- Location

- Essex, England.

Nod in a tailstock ram is rarely enough to cause problems for everyday turning. It could be 10 thou low or more and not affect the diameter enough to measure. Sideways is a different matter - any sideways misalignment is doubled in a part turned between centres so the effect is significant.

Not so much for turning, but it IS a serious issue if you have a drill or reamer in it!

Pete.

Member

- Messages

- 14,998

- Location

- Kent, UK

I tested the ram as you call it, I thought it was called the quill, the part that goes in and out of the tailstock. I used a dial indicator on the top and zeroed it with the ram fully retracted. Then I retracted the tailstock and extended the ram fully (but not so far so it left the threads) and moved the ram into position and measured, with the tailstock locked in both positions ofcourse. Total runout was 0.02mm which seems OK to me.

Less than a thou - I wish mine were that good.

DennisCA

Member

- Messages

- 2,050

- Location

- Finland

I really like the burr file I made by the way, it's handy to have for a lot of things aside from cleaning lathe ways. I had gotten a burr on a drill bit for instance (made it hard to put back in the plastic holder), and with the file I had no problems filing it off and didn't even marr the black finish on the surrounding areas. Very useful little tool.

DennisCA

Member

- Messages

- 2,050

- Location

- Finland

Regarding the new threaded rod for the 4 jaw chuck, I spent 5 minutes trying to file it without much success without I gave up. Holy moly I don't got the patience!!! My needle files are all worn out chinese junk anyway so it barely cut.

Anyway this looks more plausible for me than bothering with files, too bad I can't find ground square tool steel though. But I can find HSS, so maybe that would work, I got some carbide cutters after all...

Anyway this looks more plausible for me than bothering with files, too bad I can't find ground square tool steel though. But I can find HSS, so maybe that would work, I got some carbide cutters after all...

DennisCA

Member

- Messages

- 2,050

- Location

- Finland

Oh yeah I got a square enough hole made by using the lathe and a piece of HSS as a broach, I only had a small suitable piece and had to do each side in turn, then file the final fit. But it worked. The whole idea of making a broach fell on the simple issue that I could not find a piece of tool steel in the right size.

Still maybe I went through all the trouble with the chuck for naught. I didn't use the lathe for a good while after that but this weekend I was going to do some turning and I needed the 4-jaw to get it dialed in. Well I watched a buncha videos on dialing in 4-jaws, the method I found worked best was:

-Chuck it up as close as I could get it

-Find the low spot on the dial indicator and zero it

-Then find the high spot and divide that measurement in two

-Rotate the chuck until it reads the value in question

-Then start adjusting for zero, rotating counter clock wise all the time.

But I just wasn't able to get it properly zeroed, when I looked closer I see the reason is some of the jaws are not able to grip the precision ground rod I was using except at the back, turns out this chuck is suffering from something called "bell mouth" from what I can tell, on some jaws.

Googling and reading on practical machinist there were a lot of people there saying to people with similar issues that the chuck is junk, though some said it could be re-bored or reground. Well I don't have a tool post grinder and while I have a carbide boring bar the insert won't work on the inside (tried to set it up by chucking a bearing at the back), not enough clearance....

So not sure what next, the 3 jaw chuck is a bit clapped out as well, I figured I would have to get a new one eventually but I at least thought 4 jaws were nearly indestructible.

Still maybe I went through all the trouble with the chuck for naught. I didn't use the lathe for a good while after that but this weekend I was going to do some turning and I needed the 4-jaw to get it dialed in. Well I watched a buncha videos on dialing in 4-jaws, the method I found worked best was:

-Chuck it up as close as I could get it

-Find the low spot on the dial indicator and zero it

-Then find the high spot and divide that measurement in two

-Rotate the chuck until it reads the value in question

-Then start adjusting for zero, rotating counter clock wise all the time.

But I just wasn't able to get it properly zeroed, when I looked closer I see the reason is some of the jaws are not able to grip the precision ground rod I was using except at the back, turns out this chuck is suffering from something called "bell mouth" from what I can tell, on some jaws.

Googling and reading on practical machinist there were a lot of people there saying to people with similar issues that the chuck is junk, though some said it could be re-bored or reground. Well I don't have a tool post grinder and while I have a carbide boring bar the insert won't work on the inside (tried to set it up by chucking a bearing at the back), not enough clearance....

So not sure what next, the 3 jaw chuck is a bit clapped out as well, I figured I would have to get a new one eventually but I at least thought 4 jaws were nearly indestructible.

slim_boy_fat

Member

- Messages

- 29,188

- Location

- Scottish Highlands

Well I don't have a tool post grinder and while I have a carbide boring bar the insert won't work on the inside (tried to set it up by chucking a bearing at the back), not enough clearance....

These might help? [or, at least provide some food for thought/further searching]

DennisCA

Member

- Messages

- 2,050

- Location

- Finland

Well I bored my 4 jaw chuck with a carbide boring bar today, been setting up for this operation for quite some time, I've drilled and threaded holes in the jaws so I could mount M8 threaded rods, then I used a bearing race of suitable size to preload the jaws. Then afterwards I tested with a piece of ground precision shafting I got and I am feeling pretty pleased with the result, the needle doesn't move (1 tick = less than half a thou) until the very end were there is some gunk on the shaft. I think I went maybe 25cm or so. the shaft is not any longer. But yeah to me this looks good:

I don't know what brand the boring bar is, came with the lathe, but it had zero problems boring the jaws.

Regarding the spindle runout I talked about earlier. I have tested turning a rod and checking with the dial indicator and when something is turned it stays round and true, the needle doesn't move, I figure if the bearings are off then it would introduce random imprecision that would change over time, so that even after turning something, it would not register perfectly true.

I also stoned the spindle mating surface for the chuck with a translucent arkansas slip stone and testing the surface afterwards only show the barest of twitching on the dial indicator.

So I think the lathe is turning out to be quite precise, the ways seem to be good as well given the result of the video.

I don't know what brand the boring bar is, came with the lathe, but it had zero problems boring the jaws.

Regarding the spindle runout I talked about earlier. I have tested turning a rod and checking with the dial indicator and when something is turned it stays round and true, the needle doesn't move, I figure if the bearings are off then it would introduce random imprecision that would change over time, so that even after turning something, it would not register perfectly true.

I also stoned the spindle mating surface for the chuck with a translucent arkansas slip stone and testing the surface afterwards only show the barest of twitching on the dial indicator.

So I think the lathe is turning out to be quite precise, the ways seem to be good as well given the result of the video.