- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rexvalter VF-118 lathe (was: old Myford Ml7)

- Thread starter DennisCA

- Start date

DennisCA

Member

- Messages

- 1,981

- Location

- Finland

Today I have cleaned the rest of the parts in degreaser, oiled and reassembled the lathe again. I think the color on the lathe is in quite good shape, only bits that are really worn is the cross and top slides.

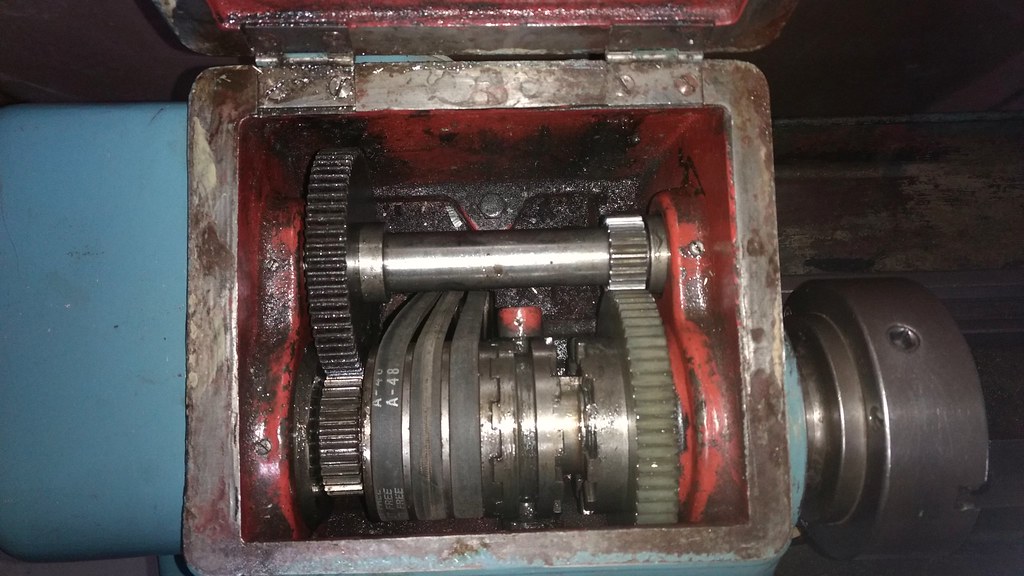

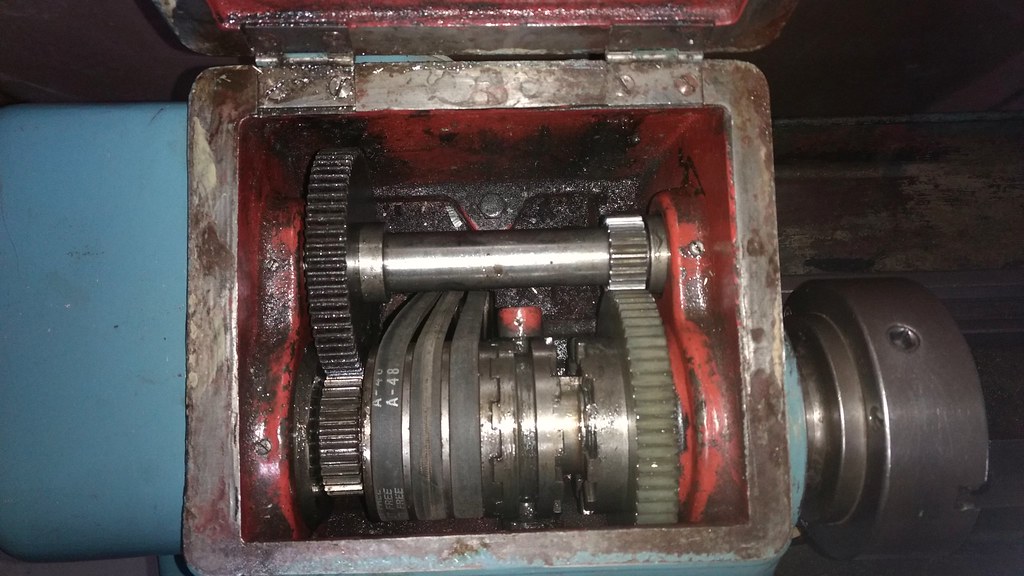

The spindle housing seen from above, I don't know how this is kept lubricated, can't find any mechanism like a pump or something to throw oil around when going.

Apron and lead screw ready for reinstall:

Assembled, using ballistol for now to oil in moving surfaces.

This little chapman kit from Brownells I got many a year ago has been such a useful piece of kit, all kinds of slotted screw drivers and the hollow ground shape instead of a chisel shape prevents cam out.

Removing the chuck showed me this, someone apparently lost one of the screws for the cover plate and put a badly fitting phillips screw there....

Reassembled, next step is to get the pallet away from under it.

The spindle housing seen from above, I don't know how this is kept lubricated, can't find any mechanism like a pump or something to throw oil around when going.

Apron and lead screw ready for reinstall:

Assembled, using ballistol for now to oil in moving surfaces.

This little chapman kit from Brownells I got many a year ago has been such a useful piece of kit, all kinds of slotted screw drivers and the hollow ground shape instead of a chisel shape prevents cam out.

Removing the chuck showed me this, someone apparently lost one of the screws for the cover plate and put a badly fitting phillips screw there....

Reassembled, next step is to get the pallet away from under it.

The spindle housing seen from above, I don't know how this is kept lubricated, can't find any mechanism like a pump or something to throw oil around when going.

As above, lightly grease the gears, try not to get it on the belts over the belts. Have a look for a grease point for the backgear to spindle lubrication.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,291

- Location

- NE London - UK

Have a look for a grease point for the backgear to spindle lubrication.

Also look for one on the bull gear.The backgear seems to be permanently driven so I would expect that the bull gear would need lubricating every time before the lathe is used.

You need a sticky grease for the gears, motorcycle chain lube or Molyslip OGL, which is specifically formulated for open gear trains.

I suggest rock oil chain lube it goes on runny but the solvent flashes off quickly leaving a very good anti-fling lube. Or open gear lube as above. IF the bull gear isn't on a roller bearing it's probably lubricated by squeeze-out grease from the front spindle bearing.

DennisCA

Member

- Messages

- 1,981

- Location

- Finland

I've done nothing since saturday, got laid out with a high fever (39c) and not before today did I wake up feeling like a human being again... The one thing I did was when I put it back together and noticed it had backlash were it didn't before, I was able to pull the cross slide back and forth, that wasn't right I felt. I figured out this was due to the gib screw settings, they were too loose, I tightened them just enough to remove the play.

DennisCA

Member

- Messages

- 1,981

- Location

- Finland

Ok guess I'll have go over it again... There is some backlash to the nut itself but I suspect I must've incorrectly adjusted the takeup at the handle.

EDIT: To make it clear, I know I was masking the play by doing this, but I assumed this is simply how it is done... all lathes have some backlash or will develop it with time as the nut wears (it's bronze, the leadscrew is steel).

EDIT: To make it clear, I know I was masking the play by doing this, but I assumed this is simply how it is done... all lathes have some backlash or will develop it with time as the nut wears (it's bronze, the leadscrew is steel).

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,291

- Location

- NE London - UK

Unless you have an adjustable backlash screw you'll never remove the play. However, even with this feature, you will find on an old lathe that you cannot adjust it out without making the travel at the ends of the screw too tight. Generally the cross slide spends most of its time going back and forth on the centre third of the thread, and this can wear it quite significantl, I speak from experience with my lathe. The only solution is to replace both the nut and screw since they both will be worn.

DennisCA

Member

- Messages

- 1,981

- Location

- Finland

This week from hell left me unable and unwilling to enter the workshop until yesterday, now I just have a cold. But I got some SAE 30 oil for general purpose lubrication of the lathe, some old fashioned motor oil for vintage pre-1950s vehicles, with little or no detergents. Seems to stick pretty OK as a way oil. Then I went to the project of getting the lathe off the pallet.

What I did was I sawed out the center of the pallet, which due to lack of access required use of a handsaw more than once from "problematic" positions.

Well I finally got the middle of the pallet cut away and removed so I could use the old scissor lift from my car to lift up one side of the lathe and remove one side of the pallet. Then I shoved in a bunch of boards I stacked to almost the same height and lowered it back down. I did the same to the other side of the lathe. From there on I lifted one side, removed one of the stacked boards and lowered it back down. Then went to the other side of the lathe and repeated the procedure until I had lowered the lathe to the floor.

Also here's the TDI for my lathe, isn't it odd it is divided into five parts, instead of 4 or 8?

What I did was I sawed out the center of the pallet, which due to lack of access required use of a handsaw more than once from "problematic" positions.

Well I finally got the middle of the pallet cut away and removed so I could use the old scissor lift from my car to lift up one side of the lathe and remove one side of the pallet. Then I shoved in a bunch of boards I stacked to almost the same height and lowered it back down. I did the same to the other side of the lathe. From there on I lifted one side, removed one of the stacked boards and lowered it back down. Then went to the other side of the lathe and repeated the procedure until I had lowered the lathe to the floor.

Also here's the TDI for my lathe, isn't it odd it is divided into five parts, instead of 4 or 8?

gaz1

Member

- Messages

- 19,276

- Location

- westyorkshire

This week from hell left me unable and unwilling to enter the workshop until yesterday,

Well I finally got the middle of the pallet cut away and removed so I could use the old scissor lift from my car to lift up one side of the lathe and remove one side of the pallet. Then I shoved in a bunch of boards I stacked to almost the same height and lowered it back down. I did the same to the other side of the lathe. From there on I lifted one side, removed one of the stacked boards and lowered it back down. Then went to the other side of the lathe and repeated the procedure until I had lowered the lathe to the floor.

i was thinking good as your workshop is way to clean but in end youve done something good by using an old method on your own to get it off the pallet

Hood

I am obsessed.

- Messages

- 17,399

- Location

- Carnoustie, Scotland

In my book, if you can see the floor it is too cleanI should take some photos of the floor elsewhere, should take care of my shop looking too clean.

MattF

Forum Supporter

- Messages

- 16,825

- Location

- South Yorkshire

In my book, if you can see the floor it is too clean

You are allowed to see the odd patch, but not more than a few feet squared.

My gauge is whether you can walk from one side to the other without walking sideways at some point, & also having to step over something.

My gauge is whether you can walk from one side to the other without walking sideways at some point, & also having to step over something.

But I got some SAE 30 oil for general purpose lubrication of the lathe, some old fashioned motor oil for vintage pre-1950s vehicles, with little or no detergents. Seems to stick pretty OK as a way oil.

If you can't source proper way oil chainsaw chain oil is a good alternative & should be easy to find in Finland!

DennisCA

Member

- Messages

- 1,981

- Location

- Finland

Some people have adviced me against chainsaw oil, and more others say proper way oil is nice but overkill. There are a lot of suggestions when you go online. I could get my hands on way oil but most answers I got seemed to think normal oil of the right viscosity would do fine. Usually when I go online and ask questions like this and there's a million different answers and opinions, what I do is find the aggregate opinion that's voiced/supported by most people.

I would probably use way oil if I could use it on everything else too, lead screws and in oiling points on the lathe. I believe Keith Fenner does this based on a video I saw last night, so maybe when I use up this batch of oil (Motul Classic SAE 50 Before 1950 Mineral Engine Oil) I'll buy some of way oil and just keep oiling the lathe with that.

I would probably use way oil if I could use it on everything else too, lead screws and in oiling points on the lathe. I believe Keith Fenner does this based on a video I saw last night, so maybe when I use up this batch of oil (Motul Classic SAE 50 Before 1950 Mineral Engine Oil) I'll buy some of way oil and just keep oiling the lathe with that.