You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

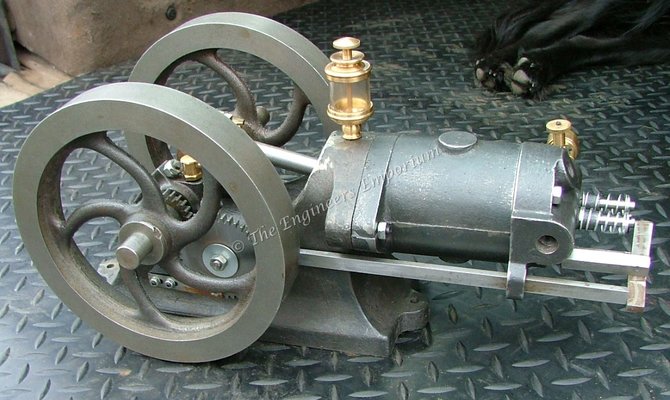

Senior project

- Thread starter Chippie

- Start date

roofman

Purveyor of fine English buckets and mops

- Messages

- 12,163

- Location

- North West with water on 3 sides

I prefer bacon and egg and it has nothing to do either with the OP,s post about building a kit enginei prefer a proper working type of one

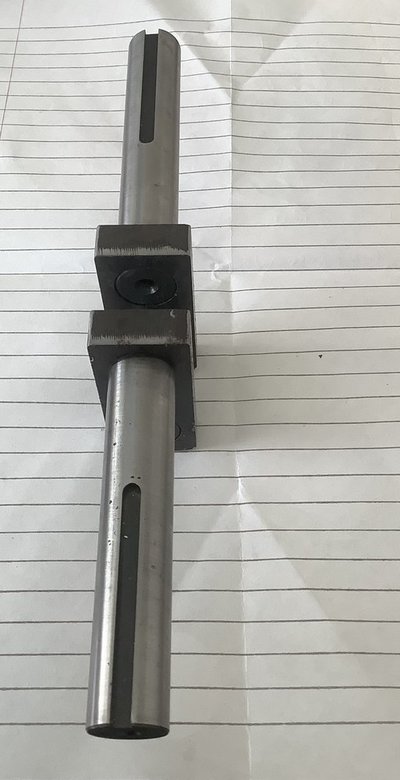

have a good look at the sliders on this

this is while in use

slim_boy_fat

Forum Supporter

- Messages

- 29,540

- Location

- Scottish Highlands

Chippie

Member

- Messages

- 855

- Location

- Newcastle upon Tyne, UK

Chippie

Member

- Messages

- 855

- Location

- Newcastle upon Tyne, UK

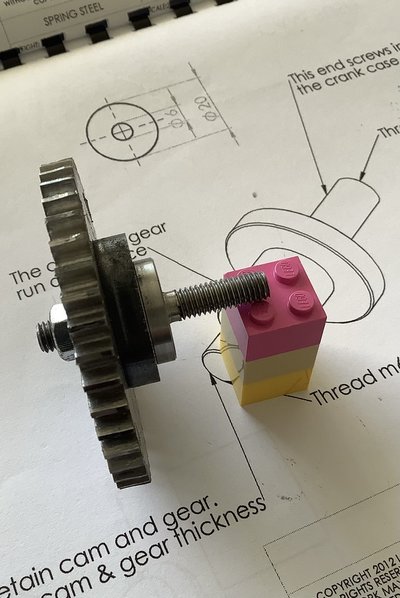

Some more parts made today, these 3 make up the rocker assembly for the ex valve…see the first post, picture…

The pivot arm looks like it was plasma cut, the surface was very hard, a file wouldn’t touch it…so I cleaned it up as best as I could without reducing its dimensions too much.

The plans call for the pivot pin to be made from ms, I decided to make it from harder wearing Silver steel, I might add a phos bronze bush to the rocker, later on.

The pivot arm looks like it was plasma cut, the surface was very hard, a file wouldn’t touch it…so I cleaned it up as best as I could without reducing its dimensions too much.

The plans call for the pivot pin to be made from ms, I decided to make it from harder wearing Silver steel, I might add a phos bronze bush to the rocker, later on.

Chippie

Member

- Messages

- 855

- Location

- Newcastle upon Tyne, UK

A bit more…..

Made a start on the con rod….(horrible thing! )

I bushed the litte end eye with some Phosphor Bronze rather than Brass….then reamed to 12mm

Although the big end is tabbed from blocks of Brass…( should have been Steel with Bearings imho..) it’s reading for final boring in the lathe to 16mm

Made a start on the con rod….(horrible thing! )

I bushed the litte end eye with some Phosphor Bronze rather than Brass….then reamed to 12mm

Although the big end is tabbed from blocks of Brass…( should have been Steel with Bearings imho..) it’s reading for final boring in the lathe to 16mm

Chippie

Member

- Messages

- 855

- Location

- Newcastle upon Tyne, UK

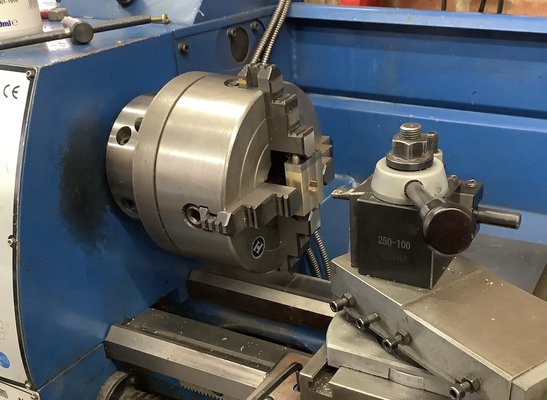

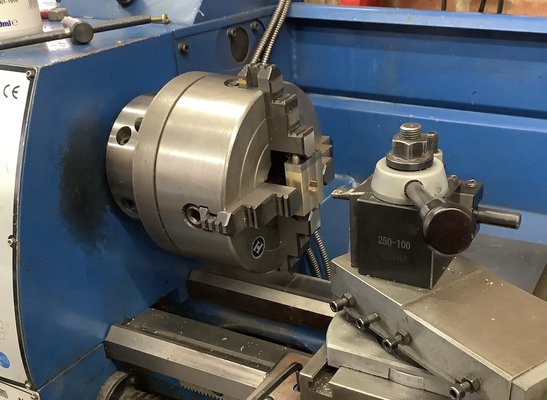

You mean, 'so things can fall on to the rotating chuck? '/Hate lathes with no raised edge behind the chuck.

I always make a fence around the head stock if flat.

I dont ordinarily have items on the top like that...for that reason...Safety first as always..

Chippie

Member

- Messages

- 855

- Location

- Newcastle upon Tyne, UK

Continued…….

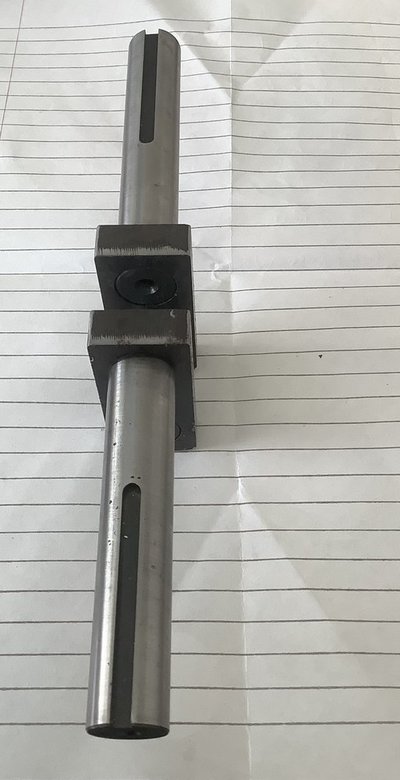

Finished the crankshaft today….

A pressed assembly, then cross drilled and pinned, with the pins silver soldered in….

The webs are black mild steel, look to have been laser cut/profiled. The main shaft and crank pin are made from EN3A….bloody hard stuff! When it came to cutting the 4mm keyways….had to use a Carbide end mill…

Finished the crankshaft today….

A pressed assembly, then cross drilled and pinned, with the pins silver soldered in….

The webs are black mild steel, look to have been laser cut/profiled. The main shaft and crank pin are made from EN3A….bloody hard stuff! When it came to cutting the 4mm keyways….had to use a Carbide end mill…

Last edited:

roofman

Purveyor of fine English buckets and mops

- Messages

- 12,163

- Location

- North West with water on 3 sides

did you cut them keyways? nice jobContinued…….

Finished the crankshaft today….

A pressed assembly, then cross drilled and pinned, with the pins silver soldered in….

The webs are black mild steel, look to have been laser cut/profiled. The main shaft and crank pin are made from EN3A….bloody hard stuff! When it came to cutting the 4mm keyways….had to use a Carbide end mill…

View attachment 421488 View attachment 421489

Chippie

Member

- Messages

- 855

- Location

- Newcastle upon Tyne, UK

Yes, milled out with a 4mm Carbide end mill….nice and sloooowww….plenty of lubricant and keep clearing the swarf….EN3B seems very hard to cut..did you cut them keyways? nice job

Misterg

Member

- Messages

- 1,061

- Location

- North Wales

I don't like using it. I bought some 'bar ends' from ebay that were supposed to be EN1, but I'm pretty sure they were EN3 - they were very silver, had pale blue paint on the ends and machined like poop.EN3B seems very hard to cut.

Enjoying the build - keep it up

Chippie

Member

- Messages

- 855

- Location

- Newcastle upon Tyne, UK

Made a start on the piston, machined from billet, finished diameter is 38mm and is 50mm long. (It is over length at the moment)

The crown is profiled, so going to need a radius on it…

Machined out the underside for the little end, need to drill and tap the bosses for the gudgeon pin retaining grub screws (M4) and machine the piston ring grooves…

Then a final clean up and polish……

The crown is profiled, so going to need a radius on it…

Machined out the underside for the little end, need to drill and tap the bosses for the gudgeon pin retaining grub screws (M4) and machine the piston ring grooves…

Then a final clean up and polish……

(sorry)

(sorry)