Chippie

Member

- Messages

- 855

- Location

- Newcastle upon Tyne, UK

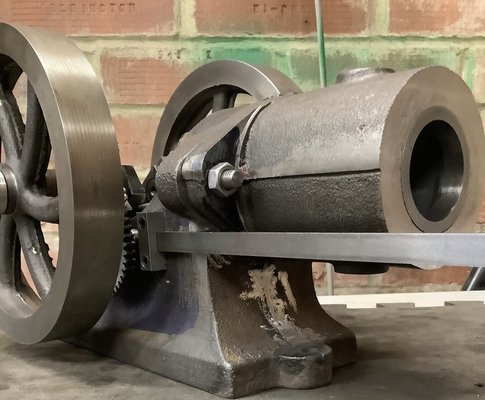

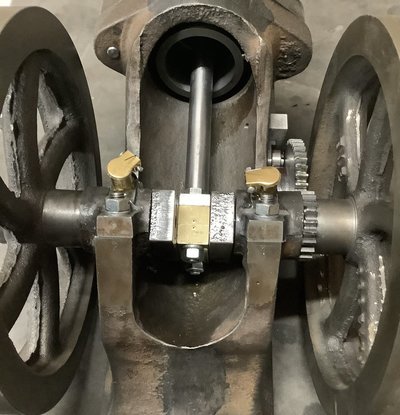

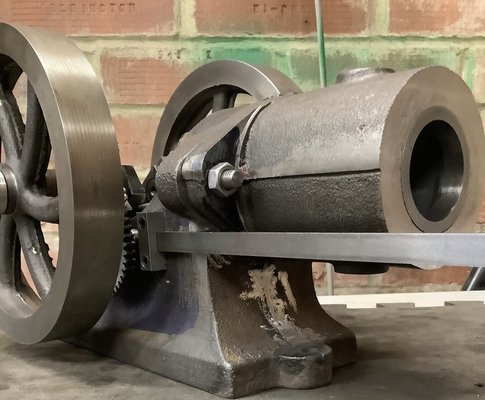

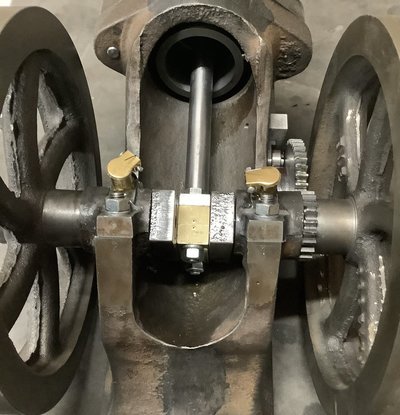

Today, attention turned to some fiddly jobs….

The crank bearing caps needed drilling and tapping for the oil dash pots, the cam timing gear needed a couple of holes, one of which is to locate the cam, which is now pinned to the gear.

The cylinder has been honed to accept the piston, with a final polish with some T cut, although the bore doesn’t need to have a mirror finish, in fact a slightly roughened surface is required to retain the oil that lubricates the bore/piston skirt.

Some photos showing how assembly is going….

The crank bearing caps needed drilling and tapping for the oil dash pots, the cam timing gear needed a couple of holes, one of which is to locate the cam, which is now pinned to the gear.

The cylinder has been honed to accept the piston, with a final polish with some T cut, although the bore doesn’t need to have a mirror finish, in fact a slightly roughened surface is required to retain the oil that lubricates the bore/piston skirt.

Some photos showing how assembly is going….