Hello and welcome to the Forum !

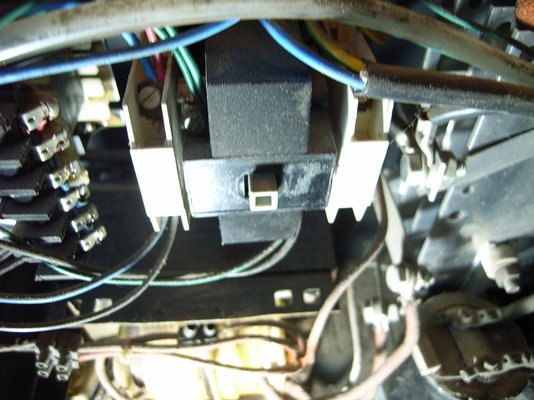

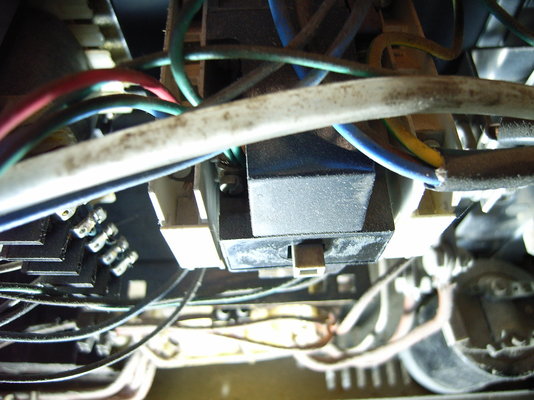

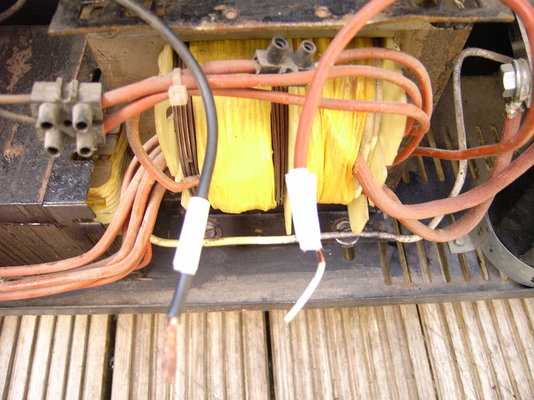

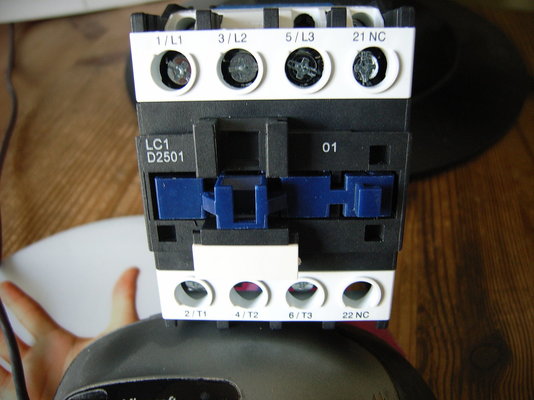

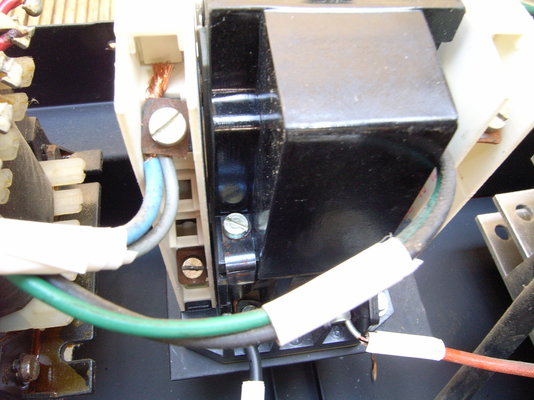

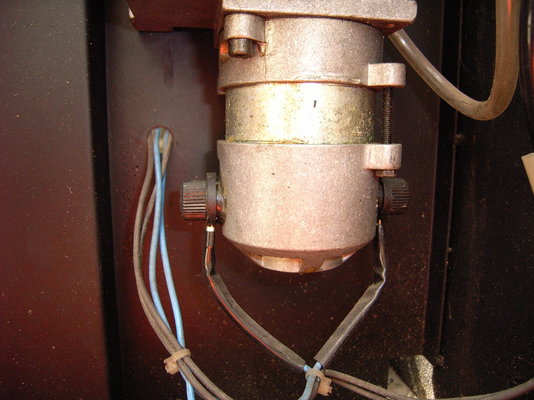

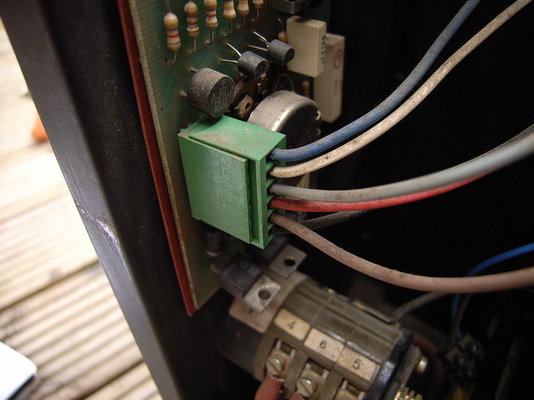

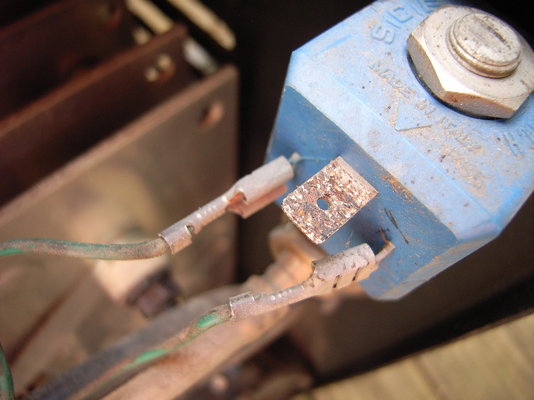

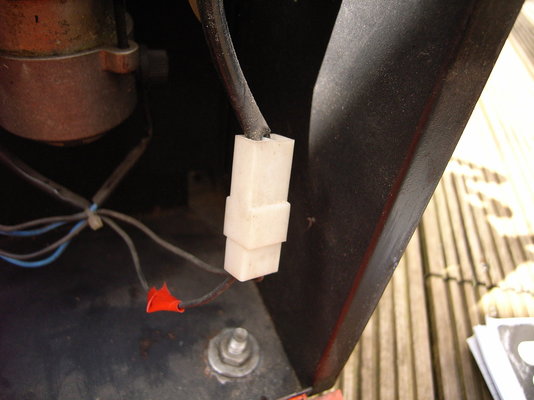

That component is the contactor. It is a large heavy-duty relay. It is operated by a solenoid coil, at 12 or 24 volts, controlled by the torch trigger switch via the small printed circuit board. The coil moves an armature which carries a set of two or three contacts. When these close, they feed AC mains to the welding transformer. The gas valve and wirefeed motor also operate at that time.

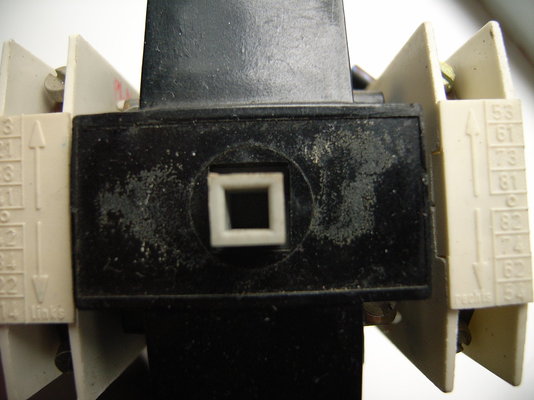

The coil and armature can attract magnetic grinding dust, which may be causing the buzzing noise. You could start by removing, opening, and cleaning the contactor. If this does not help, it can be replaced by any similar generic contactor - it's not a unique SIP part.

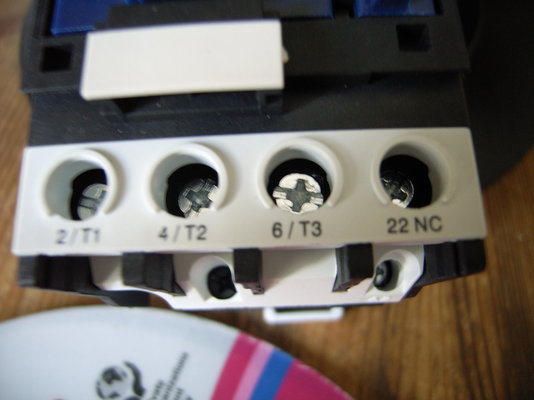

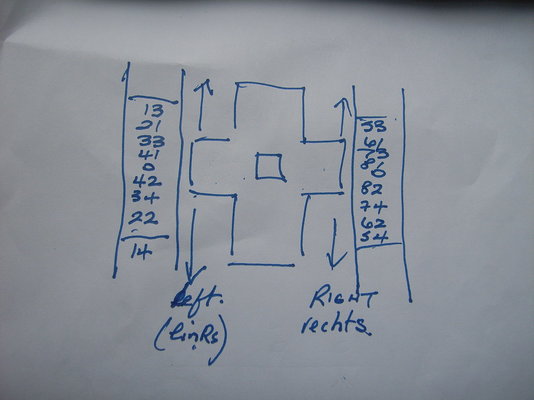

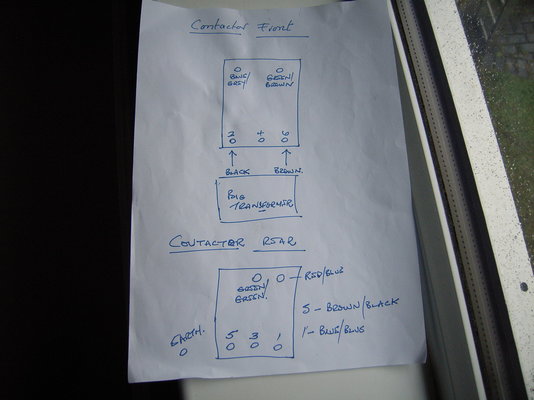

Start by switching off and unplugging the welder. Make a full and careful note of all the connections to the contactor. Do not rely on memory or photographs! The terminals should have numbers already, such as L1, L2, T1, T2. The coil terminals may be A1 and A2. If the wires are not already numbered, I prefer tie-on labels.

The contactor may be held together with spring clips, or just detents in the plastic. Remove any dust or grease, clean the moving and fixed contact faces with fine abrasive paper, re-assemble and test!

That component is the contactor. It is a large heavy-duty relay. It is operated by a solenoid coil, at 12 or 24 volts, controlled by the torch trigger switch via the small printed circuit board. The coil moves an armature which carries a set of two or three contacts. When these close, they feed AC mains to the welding transformer. The gas valve and wirefeed motor also operate at that time.

The coil and armature can attract magnetic grinding dust, which may be causing the buzzing noise. You could start by removing, opening, and cleaning the contactor. If this does not help, it can be replaced by any similar generic contactor - it's not a unique SIP part.

Start by switching off and unplugging the welder. Make a full and careful note of all the connections to the contactor. Do not rely on memory or photographs! The terminals should have numbers already, such as L1, L2, T1, T2. The coil terminals may be A1 and A2. If the wires are not already numbered, I prefer tie-on labels.

The contactor may be held together with spring clips, or just detents in the plastic. Remove any dust or grease, clean the moving and fixed contact faces with fine abrasive paper, re-assemble and test!