You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Skotl's diesel heater garage install thread

- Thread starter skotl

- Start date

skotl

Forum Supporter

- Messages

- 10,148

- Location

- Edinburgh, UK

Yeah - that's a recent "mod" as well! Previously, the press sat outside the shelf, face-on, but then I decided that was where the heater was going so it needed to get under the shelf. One multipurpose tool and a bit of bracing later...First pic. Ain't it a bugger when something's just a gnat's too tall to slide under your bench.

skotl

Forum Supporter

- Messages

- 10,148

- Location

- Edinburgh, UK

Hmmm... you think?maybe set the fuel a wee bit further from the heater and run a copper pipe , with an off tap on it jic.

Suppose it would be a bit ironic (and fiery) if the heater melted the tank...

Good thought re copper pipe - I've certainly got plenty of it. Presumably there's no reason that the tank couldn't be 6-8 feet away?

No reason at all ,, they are that far in a lorry , and the ones in my boat were twenty five feet fron the tanks ,,, be an awful shame if all the heat from the heater was in the first three mins and the next two hours was from the workshop burning down ,,, Id also add a fire extinguisher by the door again jic , way easier looking at it than looking for it.Hmmm... you think?

Suppose it would be a bit ironic (and fiery) if the heater melted the tank...

Good thought re copper pipe - I've certainly got plenty of it. Presumably there's no reason that the tank couldn't be 6-8 feet away?

skotl

Forum Supporter

- Messages

- 10,148

- Location

- Edinburgh, UK

Sold. I'll move it - cheers.No reason at all ,, they are that far in a lorry , and the ones in my boat were twenty five feet fron the tanks ,,, be an awful shame if all the heat from the heater was in the first three mins and the next two hours was from the workshop burning down ,,, Id also add a fire extinguisher by the door again jic , way easier looking at it than looking for it.

Doing surprisingly well for fire extinguishers! You'll just see the top of one to the left of the first pic and there's another one at the garage door.

skotl

Forum Supporter

- Messages

- 10,148

- Location

- Edinburgh, UK

Question for the experienced masses...

The exhaust is 25mm diameter and it's going to go through 250mm thick breeze block. I have a 25mm SDS bit so was going to wrap the exhaust with exhaust heatwrap up to the brick, but now I'm starting to wonder whether the brick will be ok with the ~300-400F exhaust going through it.

The alternative is to splurge £36 on a 30mm bit that I'll never use again and poke it through the brick with heatwrap all the way.

Any thoughts on whether the breeze block will cope with that kind of heat?

The exhaust is 25mm diameter and it's going to go through 250mm thick breeze block. I have a 25mm SDS bit so was going to wrap the exhaust with exhaust heatwrap up to the brick, but now I'm starting to wonder whether the brick will be ok with the ~300-400F exhaust going through it.

The alternative is to splurge £36 on a 30mm bit that I'll never use again and poke it through the brick with heatwrap all the way.

Any thoughts on whether the breeze block will cope with that kind of heat?

drill it in a clover leaf chip out the other bits and sleeve the hole , then put the exhaust through with some asbestos type packing to stop draughts ,,, probably not actually needed but its good practice.Question for the experienced masses...

The exhaust is 25mm diameter and it's going to go through 250mm thick breeze block. I have a 25mm SDS bit so was going to wrap the exhaust with exhaust heatwrap up to the brick, but now I'm starting to wonder whether the brick will be ok with the ~300-400F exhaust going through it.

The alternative is to splurge £36 on a 30mm bit that I'll never use again and poke it through the brick with heatwrap all the way.

Any thoughts on whether the breeze block will cope with that kind of heat?

I also tend to drill holes like that at a downwards angle too , if you can . Then if anything does go wrong unburned fuel runs out side and not inside , again probably not needed , but its as easy to drill at an angle as not. and it stops water running in from outside on wet days too.

skotl

Forum Supporter

- Messages

- 10,148

- Location

- Edinburgh, UK

Yep - had already planned to drill it down (inside to outside) to keep the rain at bay, but that point about unburned fuel ((shudder)) is also a good oneI also tend to drill holes like that at a downwards angle too , if you can . Then if anything does go wrong unburned fuel runs out side and not inside , again probably not needed , but its as easy to drill at an angle as not. and it stops water running in from outside on wet days too.

decca

Member

- Messages

- 908

- Location

- Crawcrook, Gateshead.

Had mine through the wall with a 25mm hole for 3 years with no problem at all.Question for the experienced masses...

The exhaust is 25mm diameter and it's going to go through 250mm thick breeze block. I have a 25mm SDS bit so was going to wrap the exhaust with exhaust heatwrap up to the brick, but now I'm starting to wonder whether the brick will be ok with the ~300-400F exhaust going through it.

The alternative is to splurge £36 on a 30mm bit that I'll never use again and poke it through the brick with heatwrap all the way.

Any thoughts on whether the breeze block will cope with that kind of heat?

skotl

Forum Supporter

- Messages

- 10,148

- Location

- Edinburgh, UK

Cheers for the advice re the exhaust.

I'm now thinking that it might be counter-productive to wrap it all the way to the wall, as that will just keep the exhaust super-toasty until it leaves the building. Instead I'm now thinking to wrap the first ~8" simply to protect everything else in close proximity to the heater itself, and then leave it naked for the rest of the run - partly for free heat as jsf said, and partly that at least some of that heat will get dissipated before it hits the wall...

I'm now thinking that it might be counter-productive to wrap it all the way to the wall, as that will just keep the exhaust super-toasty until it leaves the building. Instead I'm now thinking to wrap the first ~8" simply to protect everything else in close proximity to the heater itself, and then leave it naked for the rest of the run - partly for free heat as jsf said, and partly that at least some of that heat will get dissipated before it hits the wall...

Ubique

Member

- Messages

- 2,287

- Location

- East Midlands

Personally I'd insulate it to prevent condensate build-up due to rapid cooling, also have a bit of a drop on it to the outside for the same reason. Eventually the condensate will corrode the exhaust tube, letting combustion gases out in the wall or before it, a CO detector will help but you'll be getting unexplained headaches well before the detector is activated.Question for the experienced masses...

The exhaust is 25mm diameter and it's going to go through 250mm thick breeze block. I have a 25mm SDS bit so was going to wrap the exhaust with exhaust heatwrap up to the brick, but now I'm starting to wonder whether the brick will be ok with the ~300-400F exhaust going through it.

The alternative is to splurge £36 on a 30mm bit that I'll never use again and poke it through the brick with heatwrap all the way.

Any thoughts on whether the breeze block will cope with that kind of heat?

gaz1

Member

- Messages

- 20,083

- Location

- westyorkshire

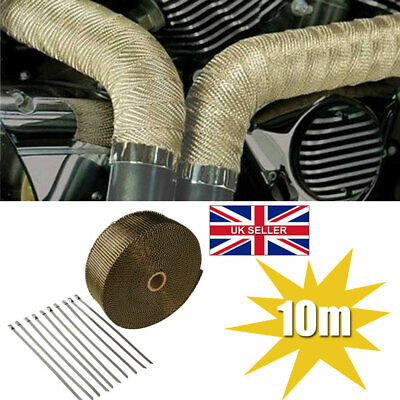

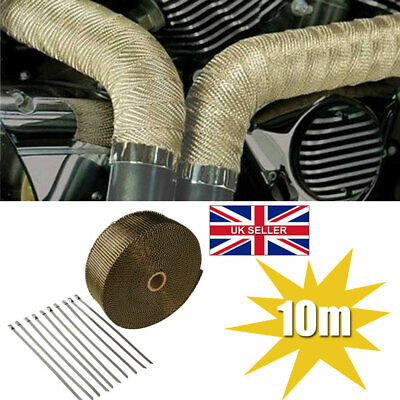

as goes for wrap

this is ample enough to use and cheaper

this is ample enough to use and cheaper

10m Titanium Exhaust Heat Wrap Manifold Downpipe High Temp Bandage Tape Roll UK | eBay

1x Exhaust Tape (10m). Length: 10m. High temperature resistance, low thermal conductivity, thermal shock resistance, low heat capacity. The exhaust heat wrap tape can withstand High temperature of 1300 degrees Celsius.

www.ebay.co.uk

500e

Always buy fire insurance a flood is a hard start

- Messages

- 9,208

- Location

- South West

Look at previous posts regarding exauust a Lot of wasted heat, we vented it into a 150mm dia pipe I think it was 40 close to htr 6mts down pipe still 20, why waste it you paid for! it pipe wants to slope down to outside for condensation reason as mentioned

as I often say , dont overthink it , get it up and running in a simple safe manner , then play with it if you dont like the results your getting , I think once its up and going you will be happy enough , they are a mighty bit of kit , make sure you have the draughts sorted out though.I’m considering running the exhaust through an EGR cooler. My particular requirement would be to heat a drum of water so that it could steadily lose heat to my (small) workshop overnight, just to reduce my leccy use for dehumidification. I’m not sure of the economics, but I think I may well have a go - just to find out.

The CO monitor/warning device will be ordered shortly.

I used a core drill to gently bore through my garage wall, at an angle, to accept a 28mm copper pipe. As the exhaust will be close-ish to foam insulation, more rock wool will be stuffed around the pipe and the heat removal may well be enough to provide a condensing atmosphere (so acidic water will need to be collected from the exhaust).

123hotchef

Member

- Messages

- 14,338

- Location

- Kent

holla if you need a egr cooler mate I have a couple here off my mitsi'sI’m considering running the exhaust through an EGR cooler. My particular requirement would be to heat a drum of water so that it could steadily lose heat to my (small) workshop overnight, just to reduce my leccy use for dehumidification. I’m not sure of the economics, but I think I may well have a go - just to find out.

The CO monitor/warning device will be ordered shortly.

I used a core drill to gently bore through my garage wall, at an angle, to accept a 28mm copper pipe. As the exhaust will be close-ish to foam insulation, more rock wool will be stuffed around the pipe and the heat removal may well be enough to provide a condensing atmosphere (so acidic water will need to be collected from the exhaust).