It would be good if the electrodes could be fed with an Ac signal. That would stop the electrolysis.

never thought of that or came across it with my earlier googling, but has been said before there is an expert for most things on here, and this could be your specialist subject. After your post I started googling again and there is a LM1830 chip available for about £10, so with a a different power supply (higher voltage) it would be a possibility to use. If I have to remove the boiler for inspection once a year, changing electrodes shouldnt be an issue, but only time will tell and its always good to have a plan B to fall back on.

http://pdf.datasheetcatalog.com/datasheet/nationalsemiconductor/DS005700.PDF

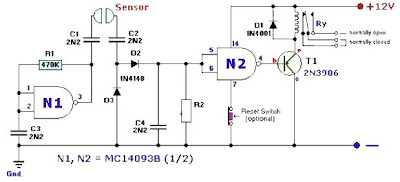

http://www.circuitstoday.com/liquid-level-indicator

I also made a safety valve .filler plug for the boiler last last week. I've decided that I like to have fluted edges rather than knurling to grip things and here Im milling the flutes (using a ball nosed mill) around the top lip of the safety valve body after turning it on the lathe.

and the machining the inside of the valve, using a D bit to cut the seat for the ball and threading it to fit the spring adjuster.

and making the spring adjuster, its one of those fiddly little jobs, its threaded 5mm o/d and had 4 slots cut along its length to let the steam out.

and the finished parts of the safety valve which will operate at 25psi.

.

.