You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Smoking windings - Murex Autolynx

- Thread starter jo1010

- Start date

charliecambs

Member

- Messages

- 109

- Location

- cambridgeshire

I have wirefeed and clunk from contactor and 240 volts on its coil.So it works ( appart from contactor contacts.

Not 100% sure on the trigger mode control but have on/off as normal and tap on tap off. Need to look at others but don't tend to use them on other machine.

Contactor and capacitor bleed here tomorrow.

@eddie49 - do you know operation in stith spot modes and approx max/min times??

charliecambs

Member

- Messages

- 109

- Location

- cambridgeshire

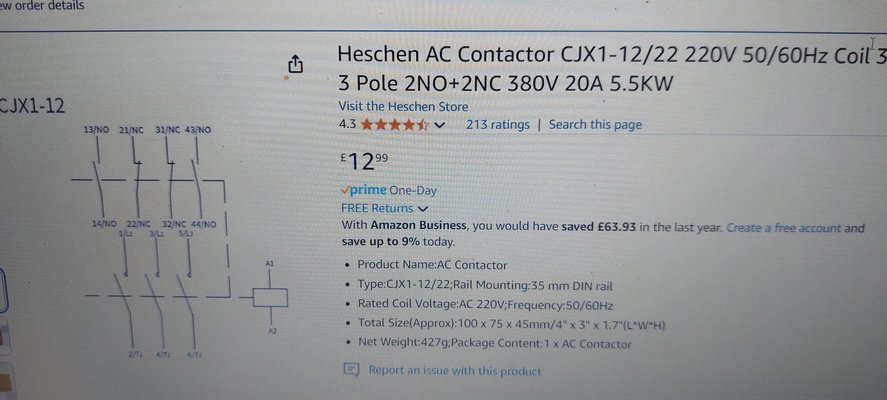

@eddie49not many contactors ( in my cheapskate price range) that have nc aux contacts. Amazon have 20amp with 2 aux nc and 2 no and I had a 10% off and have 2 25w 1 ohm resistors too.Note that the contactor has additional Normally Closed contacts, which put the bleed resistor across the capacitor bank at idle. There are actually two sets of NC contacts, with each end the resistor supported by the terminal screws.

Spend so far £50 on welder as I did buy now and £15 on bits ( I hope)

I don't know the Spot and Stitch timer values - probably a few seconds I guess.

Rather than 1 Ohm ( a typo perhaps? ), the bleed resistor should be 27 Ohms:

An Eland MIG for £50 is a really good bargain - especially since it apparently works!

Rather than 1 Ohm ( a typo perhaps? ), the bleed resistor should be 27 Ohms:

Tradesmig 245 mystery component

Was inside my tradesmig investigating wire feed issues which I believe is the pot and have a new one coming tomorrow but while there spotted what I think is some kind of 'add on' resistor which has at some point broken one of its legs as it was just left hanging. . Any ideas as to its...

www.mig-welding.co.uk

charliecambs

Member

- Messages

- 109

- Location

- cambridgeshire

Start bid was £35 but as I had to coordinate pick up and relatives visit I thought buy it now was best.I don't know the Spot and Stitch timer values - probably a few seconds I guess.

Rather than 1 Ohm ( a typo perhaps? ), the bleed resistor should be 27 Ohms:

An Eland MIG for £50 is a really good bargain - especially since it apparently works!Tradesmig 245 mystery component

Was inside my tradesmig investigating wire feed issues which I believe is the pot and have a new one coming tomorrow but while there spotted what I think is some kind of 'add on' resistor which has at some point broken one of its legs as it was just left hanging. . Any ideas as to its...www.mig-welding.co.uk

I was looking at capacitor prices and there's more than £50 worth albeit old.

Hopefully get bits fitted tomorrow. I only have .8/1 drive roller and .7kg .8 wire but sure I can bodge for a test

charliecambs

Member

- Messages

- 109

- Location

- cambridgeshire

Whilst waiting for window to swap contactor my mind drifted to " bells and whistles"Start bid was £35 but as I had to coordinate pick up and relatives visit I thought buy it now was best.

I was looking at capacitor prices and there's more than £50 worth albeit old.

Hopefully get bits fitted tomorrow. I only have .8/1 drive roller and .7kg .8 wire but sure I can bodge for a test

@eddie49 have you tried those ebay battery monitors that measure volts and amps DC? There are some with a stated range to 200A and seem to have the standard 75mV shunt. ( i ignored those with an internal shunt) thinking shunt in series with work return, voltage sense from smoothing caps ( accessible easily) giving real time voltage and current?

Once I've proved ekand works I might give it a try.

Amazon " ronlok pzem015 digital but similar cheaper..

Think tool budget done for this month though!

I like this kind of electronics got my degree in 1982 and worked in mainly military electronics for 40 some years. There were still products based on basic op-amps, transistors etc in use!

charliecambs

Member

- Messages

- 109

- Location

- cambridgeshire

Well all cleaned out new contactor and everything works. My bodge 0.8 wire didn't run well due to spool brake.

I've cleaned up case outers but left paint chips and so on and varnished.

Thought it should show it's history of earning someone a living for maybe 40 years!

I'll calibrate wirespeed dial once the 5kg reel arrives. As I shared torch and work return from my " special car" total cost sits at about £60 ( plus odds and ends of paint and self tappers from my stocks)

Think it'll well outlast me!

I've cleaned up case outers but left paint chips and so on and varnished.

Thought it should show it's history of earning someone a living for maybe 40 years!

I'll calibrate wirespeed dial once the 5kg reel arrives. As I shared torch and work return from my " special car" total cost sits at about £60 ( plus odds and ends of paint and self tappers from my stocks)

Think it'll well outlast me!

jo1010

Member

- Messages

- 354

- Location

- West Berkshire, uk

Back to the original Autolynx from the start of the thread. It was quite close to me so thought I'd take a punt on it - I've also got a fully working auto lynx 3 so at worst it could be a spares machine (at £35 buy it now) for mine.......as expected the transformer had a meltdown ......maybe due to a bad rectifier diode?

So if I changed the transformer and checked or rebuilt the rectifier I could have a working machine? So I looked to see what else is around...

Second pic is a very local tradesmig 160 - also 6 step voltage so maybe a good candidate to swap the transformer - only problem there is that seller says it trips the house MCB on low power - so it could also have a transformer fault (but more likely diodes?). If I took along a 5kv insulation tester would this adequately test the transformer side of things (decoupling it from the rectifier to do that test).....

So if I changed the transformer and checked or rebuilt the rectifier I could have a working machine? So I looked to see what else is around...

Second pic is a very local tradesmig 160 - also 6 step voltage so maybe a good candidate to swap the transformer - only problem there is that seller says it trips the house MCB on low power - so it could also have a transformer fault (but more likely diodes?). If I took along a 5kv insulation tester would this adequately test the transformer side of things (decoupling it from the rectifier to do that test).....

jo1010

Member

- Messages

- 354

- Location

- West Berkshire, uk

Looking more closely at the 160 Transformer - looks like blackened insulation on one side of the primary, means this could be bad too? I haven't inspected this in person so it could just be dirt? Would <2ohm resistance measurements between input and tappings be enough to prove usefulness,

charliecambs

Member

- Messages

- 109

- Location

- cambridgeshire

That does look fun doesn't it. Haven't fully tried the eland but think it was better choice! Although you have to say he was honest......OR ..just rewind the original burnt primary with copper (and fix the rectifier diodes) .....that sounds like an exciting project

Looking at picture isn't that the secondary that's crispy?. Only two connections?

To rewind it I guess you'd ideally need to split core to get access to unwind/ rewind.

At least copper should be annealed.

jo1010

Member

- Messages

- 354

- Location

- West Berkshire, uk

@charliecambs ..haha yes my logic was back to front,....having looked around the machine it's clearly been very hot for a while...

....even the tappings show some scorching where they exit l the transformer ..

And I also found that the wire feed roller was so tight against the feed tube that I couldn't even get a 0.04 feeler gauge in.

Could that immense loading stress the circuitry so much to cause transformer overheat (I would have thought the wire feed motor would have burnt out first though).

I'm pending further investigation until a new DMM arrives though...my very old one is quite erratic atm...

But I must admit the thought of splitting the core with buckets of acetone on hand is a little daunting lol

....even the tappings show some scorching where they exit l the transformer ..

And I also found that the wire feed roller was so tight against the feed tube that I couldn't even get a 0.04 feeler gauge in.

Could that immense loading stress the circuitry so much to cause transformer overheat (I would have thought the wire feed motor would have burnt out first though).

I'm pending further investigation until a new DMM arrives though...my very old one is quite erratic atm...

But I must admit the thought of splitting the core with buckets of acetone on hand is a little daunting lol

Colin Barron

Member

- Messages

- 225

Unless you are interested in repairing this welder yourself then it is beyond economic repair, old migs are cheap and if you like this model find another second hand and make a good one out of the two. The overheated windings are probably not the cause of the problem.

jo1010

Member

- Messages

- 354

- Location

- West Berkshire, uk

Good point. I originally bought this as a spares machine for an autolynx 3 that I have (that one produces some sublime welds) ......but I then started to see a learning opportunity in actually repairing the spares machine. I know that doesn't make strict sense but I do car restorations so I'm applying that mindset to welding machines, rightly or wrongly . So I'm not thinking purely economics here, but more about creating sustainable quality and broadening skills to boot. I do need something like a 101 in the theory of transformer welders so I'll gladly receive suggestions/links about this...Unless you are interested in repairing this welder yourself then it is beyond economic repair, old migs are cheap and if you like this model find another second hand and make a good one out of the two. The overheated windings are probably not the cause of the problem.

mike 109444

Member

- Messages

- 4,810

It could be rewound but not for the faint hearted !

Note the primary had two different sizes of wire along it's length. You may be able to see if this is the case on yours when you look at the tappings. Your main cost maybe in the secondary winding due to it being much thicker (copper strip) The secondary in the one I rewound was ally. I was tempted to replace with copper BUT would not know the equivlent size or length so I cleaned up the orignal and as I rewound it over the primary I wraped it in ptfe tape (made up a wraping tool) which I also used on the primary to protect the wire while winding. Ptfe tape is a very good insulator and even the thicker stuff (for gas) is still very thin. I was able also to add more tapps as I rewound the primary allowing me to increase the potental power steps for the orignal 6 to 12. Items needed wise you are looking at possible two sizes of primary ENAMAL COATED wire, the correect type of varnish, insulated sleeving for the taps. I also used some glass fiber mat I had to wrap the tuffnal core which I also had to rebuild. Note you wont be able to do what the orignal manufactures did when it was made, namely dip it in a vat of varnish under a vacuum to suck out any air between layers. You will also need to check the choke transformer as that has "seen" the same overload on the output and may also be cooked (mine was!).

Was it worth it....

Well The machine was a sturdy built rig A Bora mig, bought as a "not working" I think the bolt for a fuse in the plug did not help.

You do learn a lot about transformers and the cost of copper wire.

You can up grade the number of power selections on a mig (a suitable switch (s) would be needed.

The machoine worked well after but sadly was distroyed in a fire at my place ( not caused by the welder !)

Ref your diode issue I think you will find that very similar diodes are used in car alternators but it might be easer to use stud mout ones.

Note the primary had two different sizes of wire along it's length. You may be able to see if this is the case on yours when you look at the tappings. Your main cost maybe in the secondary winding due to it being much thicker (copper strip) The secondary in the one I rewound was ally. I was tempted to replace with copper BUT would not know the equivlent size or length so I cleaned up the orignal and as I rewound it over the primary I wraped it in ptfe tape (made up a wraping tool) which I also used on the primary to protect the wire while winding. Ptfe tape is a very good insulator and even the thicker stuff (for gas) is still very thin. I was able also to add more tapps as I rewound the primary allowing me to increase the potental power steps for the orignal 6 to 12. Items needed wise you are looking at possible two sizes of primary ENAMAL COATED wire, the correect type of varnish, insulated sleeving for the taps. I also used some glass fiber mat I had to wrap the tuffnal core which I also had to rebuild. Note you wont be able to do what the orignal manufactures did when it was made, namely dip it in a vat of varnish under a vacuum to suck out any air between layers. You will also need to check the choke transformer as that has "seen" the same overload on the output and may also be cooked (mine was!).

Was it worth it....

Well The machine was a sturdy built rig A Bora mig, bought as a "not working" I think the bolt for a fuse in the plug did not help.

You do learn a lot about transformers and the cost of copper wire.

You can up grade the number of power selections on a mig (a suitable switch (s) would be needed.

The machoine worked well after but sadly was distroyed in a fire at my place ( not caused by the welder !)

Ref your diode issue I think you will find that very similar diodes are used in car alternators but it might be easer to use stud mout ones.

mike 109444

Member

- Messages

- 4,810

FYI

before and after

before and after

jo1010

Member

- Messages

- 354

- Location

- West Berkshire, uk

@mike 109444 Thanks! Really excellent insights. I'll spend some time later and study your process in more detail which will help immensely.

One question - the main transformer plates on mine are welded together (grind the welds off before releasing the plates) and the welds were also extended to the support bracket.

So lots of acetone to soften the varnish first, and then re-weld following the rewind.... (The inductor plates are bolted making that easier if I need to do that as well)...fascinating stuff though!

One question - the main transformer plates on mine are welded together (grind the welds off before releasing the plates) and the welds were also extended to the support bracket.

So lots of acetone to soften the varnish first, and then re-weld following the rewind.... (The inductor plates are bolted making that easier if I need to do that as well)...fascinating stuff though!

mike 109444

Member

- Messages

- 4,810

I would be caerful using acetone as it may affect the bobbin (tuffnal) material as if it is still usable it will save cost and flaff.

I am sure mine was not welded. Think I used a wallpaper type scraper to part the E's and I's of the lamanated core. Key thing is as you unwrap it you count and note the turns and diameter of wire. There maywell be additional unused taps on primary for 200, 220, 240 volt setup.

I am sure mine was not welded. Think I used a wallpaper type scraper to part the E's and I's of the lamanated core. Key thing is as you unwrap it you count and note the turns and diameter of wire. There maywell be additional unused taps on primary for 200, 220, 240 volt setup.

mike 109444

Member

- Messages

- 4,810

Think you would need to grind a "V" slot across those welds to remove them. Then tap the scraper blade between each leaf to break bond. If there are no bolts holding it together then mabe think about adding them before stripping it. Think it's welded to stop the lamanates from vibrating in use.