- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

South Bend Heavy 10

- Thread starter Pete.

- Start date

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

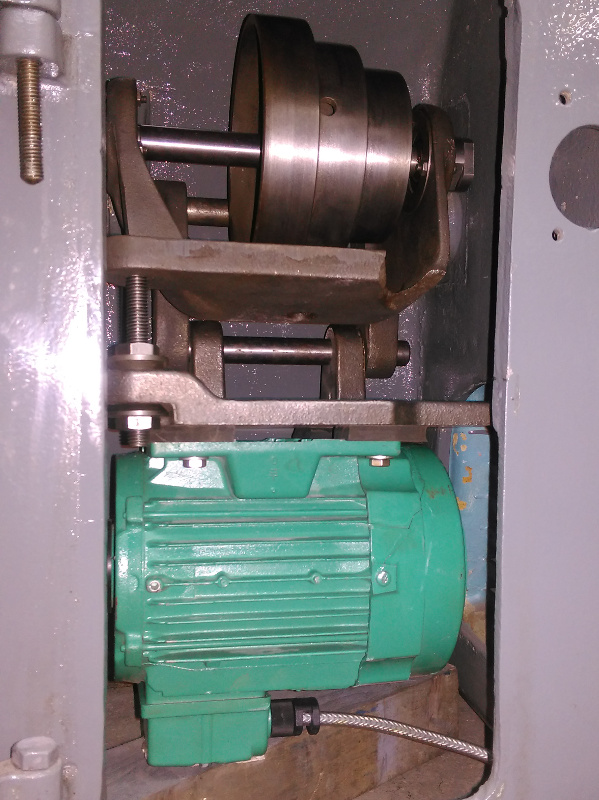

This past week I've snatched a few hours here and there to do a bit on this lathe. I've stripped the underdrive unit, cleaned off years of crud and flaky paint and rebuilt it with a new 3 phase motor. The tensioner mechanism is broken off so I'll have to make something suitable.

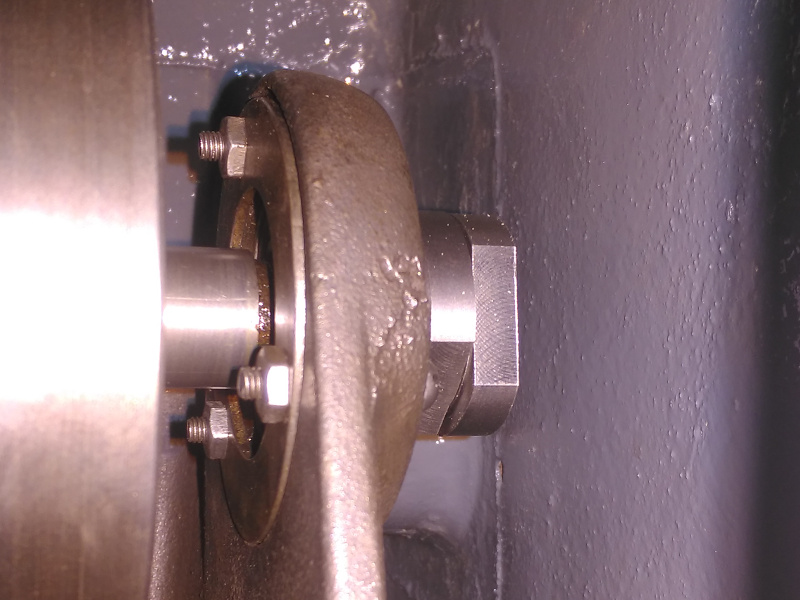

Here's the two 3/4UNF nuts I made for the countershaft

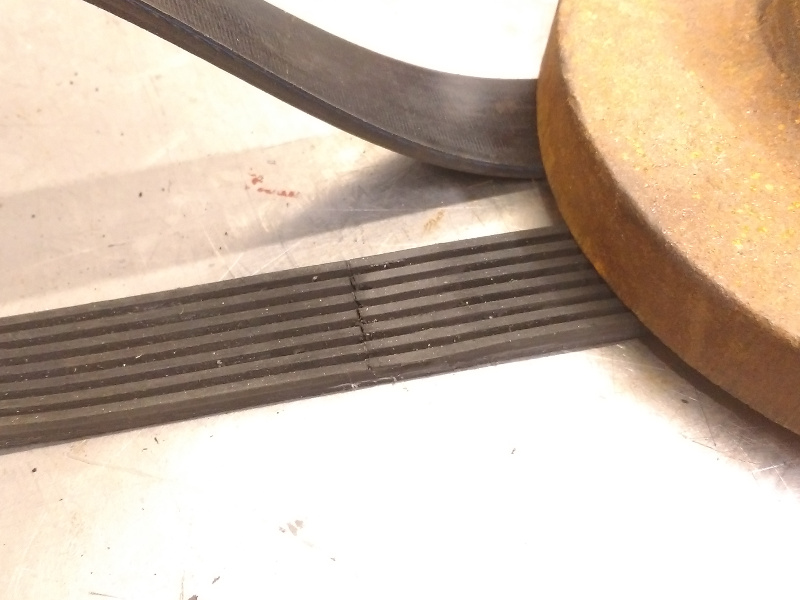

I also bought a Gates poly-v belt to replace the old flat leather belt that was original. The only problem is that you cannot fit an endless belt to a South Bend so it must be cut and joined. Someone on the South Bend forum had found that you can lap these belts by grinding them down to the aramid fibres both sides and using superglue so I figured I'd do the same. I bought an over-length belt off eBay and cut it then did a quick test to see how it would go.

Ground the belt ends for a nice lap

Clamped it up with superglue and got a nice joint out of it.

I couldn't break that 3/4" lap with all my strength so I measure the belt and cut a 3" lap in the ends.

So far so good and I've left it clamped up on a thick piece of scrap acetal overnight.

Here's the two 3/4UNF nuts I made for the countershaft

I also bought a Gates poly-v belt to replace the old flat leather belt that was original. The only problem is that you cannot fit an endless belt to a South Bend so it must be cut and joined. Someone on the South Bend forum had found that you can lap these belts by grinding them down to the aramid fibres both sides and using superglue so I figured I'd do the same. I bought an over-length belt off eBay and cut it then did a quick test to see how it would go.

Ground the belt ends for a nice lap

Clamped it up with superglue and got a nice joint out of it.

I couldn't break that 3/4" lap with all my strength so I measure the belt and cut a 3" lap in the ends.

So far so good and I've left it clamped up on a thick piece of scrap acetal overnight.

slim_boy_fat

Member

- Messages

- 29,186

- Location

- Scottish Highlands

Someone on the South Bend forum had found that you can lap these belts by grinding them down to the aramid fibres both sides and using superglue

When I bought my first [RandA] lathe, I did similar, but with balata belting [iirc from Lathes & Co] - it did the job and the lathe went away with it still on it. Not as neat as yours, though

Bill Edwards

Member

- Messages

- 4,935

- Location

- Scarborough, North Yorkshire

I also bought a Gates poly-v belt to replace the old flat leather belt that was original. The only problem is that you cannot fit an endless belt to a South Bend so it must be cut and joined. Someone on the South Bend forum had found that you can lap these belts by grinding them down to the aramid fibres both sides and using superglue so I figured I'd do the same. I bought an over-length belt off eBay and cut it then did a quick test to see how it would go.

Ground the belt ends for a nice lap

View attachment 172781

Clamped it up with superglue and got a nice joint out of it.

View attachment 172782

I couldn't break that 3/4" lap with all my strength so I measure the belt and cut a 3" lap in the ends.

View attachment 172783

View attachment 172784

So far so good and I've left it clamped up on a thick piece of scrap acetal overnight.

View attachment 172785

I think superglue can vary, but the good stuff is cured within ten seconds and used correctly (some things it isn’t suitable for) it’s incredibly strong. You might well find that if you tried to break the joint another part of the belt could break first - I’ve found that the bond to rubber is stronger than the rubber itself.

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

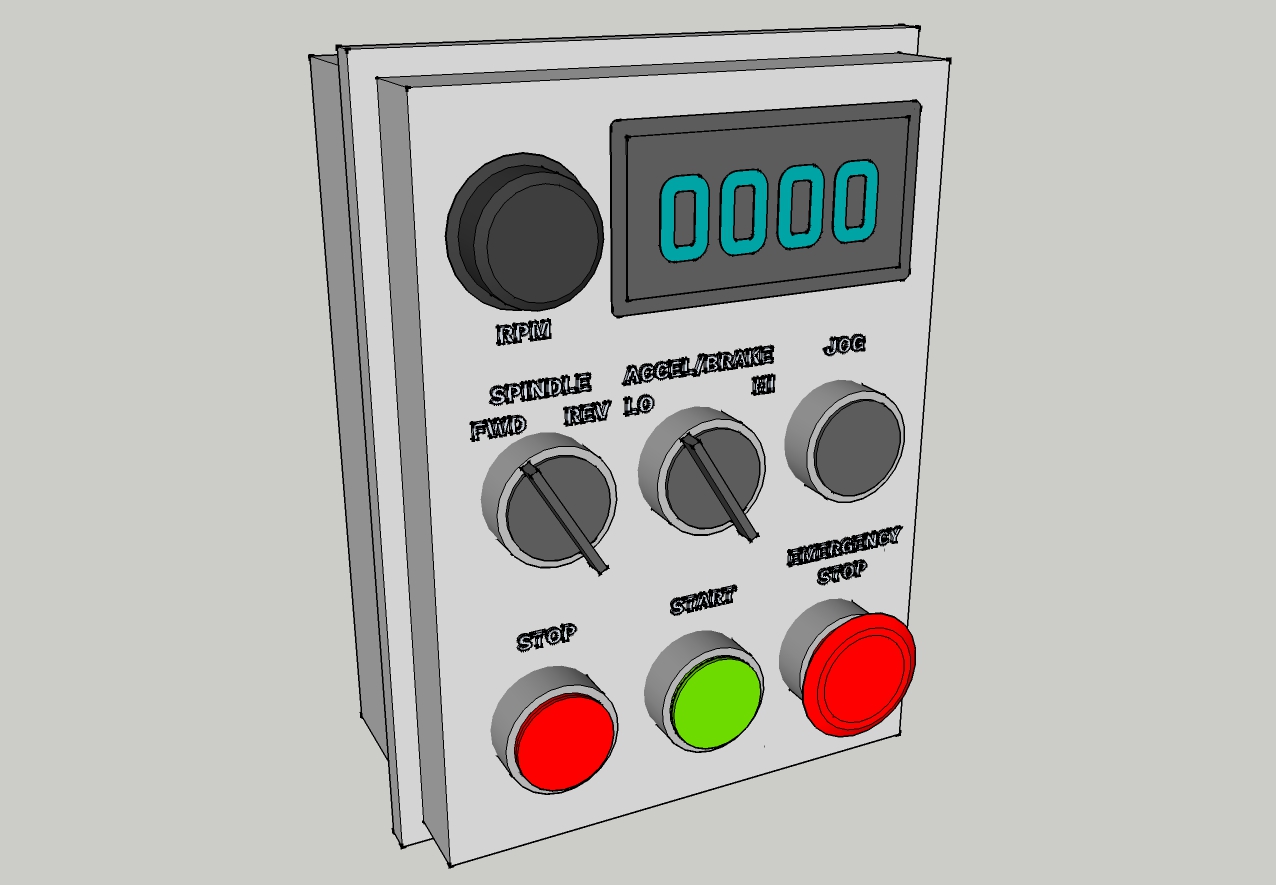

I'm thinking of this arrangement for the VFD controls. The Yaskawa VFD is very configurable (and has a headache-inducing 500 page manual) so there's a lot of features I could use but I've stuck with just adding JOG at 6hz and two rates of braking/accelleration so it can be stopped very quickly in back gear for threading etc.

I have all the parts (and already have it working in an old housing for testing) except for the digital RPM but that's on order. I'm going to build it all into the plastic enclosure I got today but I'm not sure I'll be happy with the plastic bit on a 1943 lathe. If not I might try painting it to try to disguise it's 'plasticness' and if I still don't like that I'll look around for a cast aluminium box instead.

I have all the parts (and already have it working in an old housing for testing) except for the digital RPM but that's on order. I'm going to build it all into the plastic enclosure I got today but I'm not sure I'll be happy with the plastic bit on a 1943 lathe. If not I might try painting it to try to disguise it's 'plasticness' and if I still don't like that I'll look around for a cast aluminium box instead.

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,699

- Location

- North Kent, UK

Looking good Pete!

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

Dont fancy doing mine

Got enough on my plate mate. Work has got going and now I'm going to struggle to get any of my own stuff done.

Anyway, got home from work today and found that my digital tacho had arrived so I jury-rigged it into life and stuck the magnet on the end of a screwdriver so I could waggle it past the sensor to simulate the shaft rotation.

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,699

- Location

- North Kent, UK

Got enough on my plate mate. Work has got going and now I'm going to struggle to get any of my own stuff done.

Anyway, got home from work today and found that my digital tacho had arrived so I jury-rigged it into life and stuck the magnet on the end of a screwdriver so I could waggle it past the sensor to simulate the shaft rotation.

View attachment 175336

Looking good Pete. Looks a whole load better that plastic box from McDonalds that I used in mine!

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

Some progress made again on this. I've scrapped the idea of the big control box above as it just looks too out of place. Now the VFD is mounted on a bracket on the motor plate and accessible through the front cabinet door I've simplified the controls to On/off, fwd/rev, speed pot and tacho.

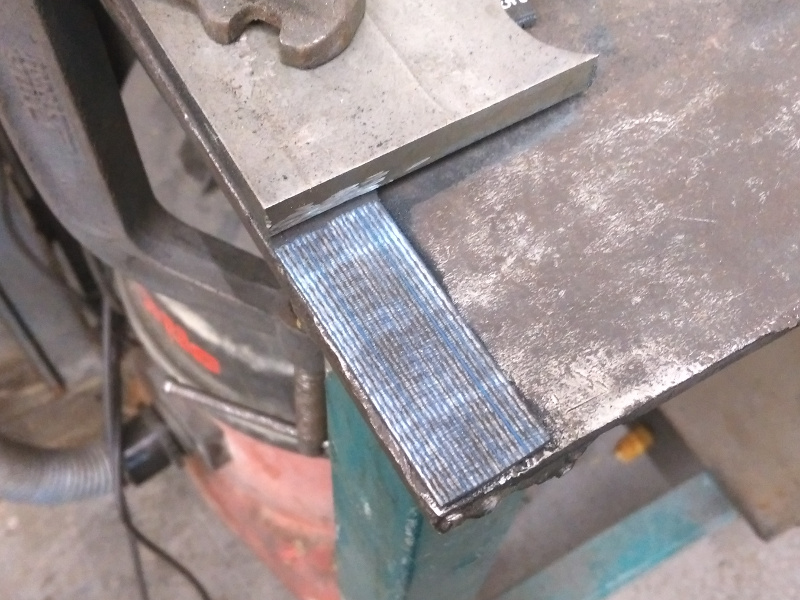

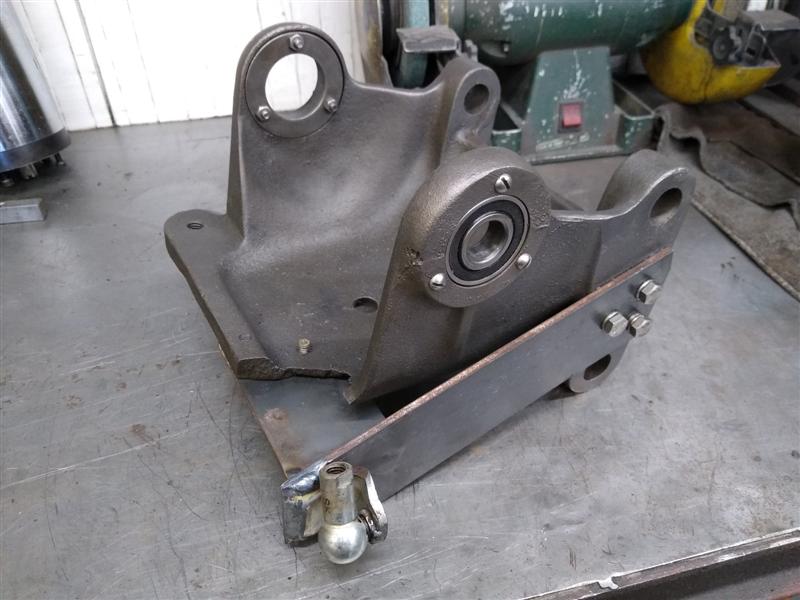

Before that can go in I've got to address the problem of the broken tensioner in post #124. The casting has been broken in the past and the whole tensioner system removed. I've fabricated a simple bracket and welded a ball and socket connector salvaged from a heavy door closer. This will do the tensioning now, which won't be often since the VFD will take care of most speed adjustment.

Needs a lick pf paint before I fit it back in. What I am in two minds over is whether to put the tensioner handle (which I don't have) in the original position OR put an E-Stop button in that hole an move the now-seldom-needed tensioner lever round the side where those other 3 holes are.

My heart is saying put the handle on the front but my head is saying put an E-stop there where it's handy for the knee if you're running the lathe or for your hand if you've got your head in the cabinet. If It's going to be non-standard anyway why not make better use of the front hole?

Before that can go in I've got to address the problem of the broken tensioner in post #124. The casting has been broken in the past and the whole tensioner system removed. I've fabricated a simple bracket and welded a ball and socket connector salvaged from a heavy door closer. This will do the tensioning now, which won't be often since the VFD will take care of most speed adjustment.

Needs a lick pf paint before I fit it back in. What I am in two minds over is whether to put the tensioner handle (which I don't have) in the original position OR put an E-Stop button in that hole an move the now-seldom-needed tensioner lever round the side where those other 3 holes are.

My heart is saying put the handle on the front but my head is saying put an E-stop there where it's handy for the knee if you're running the lathe or for your hand if you've got your head in the cabinet. If It's going to be non-standard anyway why not make better use of the front hole?

Carl Wilson

Member

- Messages

- 2,016

- Location

- Moray

Inspiring work. Is it Paragon paints stuff you've used to paint the machine?

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,699

- Location

- North Kent, UK

Some progress made again on this. I've scrapped the idea of the big control box above as it just looks too out of place. Now the VFD is mounted on a bracket on the motor plate and accessible through the front cabinet door I've simplified the controls to On/off, fwd/rev, speed pot and tacho.

Before that can go in I've got to address the problem of the broken tensioner in post #124. The casting has been broken in the past and the whole tensioner system removed. I've fabricated a simple bracket and welded a ball and socket connector salvaged from a heavy door closer. This will do the tensioning now, which won't be often since the VFD will take care of most speed adjustment.

View attachment 202475

View attachment 202474

Needs a lick pf paint before I fit it back in. What I am in two minds over is whether to put the tensioner handle (which I don't have) in the original position OR put an E-Stop button in that hole an move the now-seldom-needed tensioner lever round the side where those other 3 holes are.

View attachment 202476

My heart is saying put the handle on the front but my head is saying put an E-stop there where it's handy for the knee if you're running the lathe or for your hand if you've got your head in the cabinet. If It's going to be non-standard anyway why not make better use of the front hole?

Go with your head!

Pete.

Forum Supporter

- Messages

- 15,072

- Location

- Kent, UK

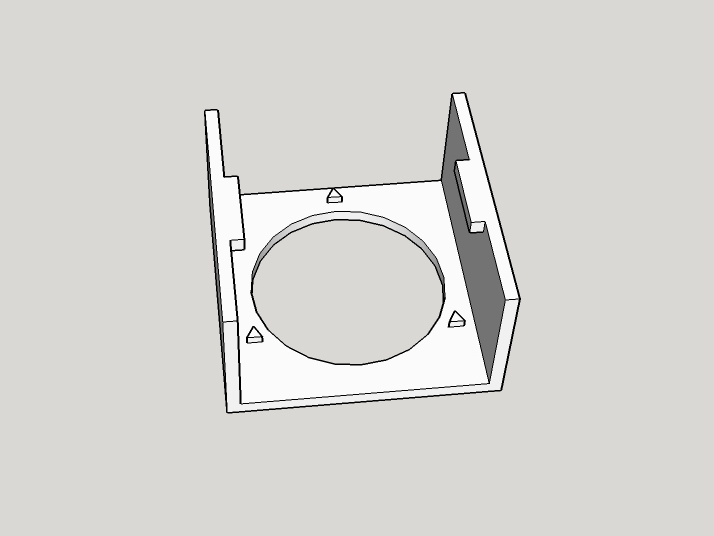

I decided to go with that and made a cover plate to hold my new E-Stop button. The button came out of one of those yellow plastic boxes so I had to find a way to mount the switch. Enter my new toy - a 3D printer. I quickly drew up a plastic clip and 15 minutes later had a switch mount printed out that also doubles-up as a spanner for the plastic retaining nut.

I've also turned up new hinge pins for the door from some stainless bar.

I've also turned up new hinge pins for the door from some stainless bar.