You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stainless ride-on mower cutting deck - good idea?

- Thread starter Benpointer

- Start date

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

Yeah I thought about that as an option. Any ideas how much it would cost to hot dip a cutting deck?Why not steel and hot dip galv?

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,519

- Location

- Sevenoaks, UK

@Bobupndown , best pics I can do:

Notch the flanges with a slitting disc. I went every 10mm. Bend tabs up / down. Bend round the mower deck. Just tweak till it fits.

Cut the overlap off:

Weld the resultant gaps up.

Notch the flanges with a slitting disc. I went every 10mm. Bend tabs up / down. Bend round the mower deck. Just tweak till it fits.

Cut the overlap off:

Weld the resultant gaps up.

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

What thickness steel is that Bob?@Bobupndown , best pics I can do:

Notch the flanges with a slitting disc. I went every 10mm. Bend tabs up / down. Bend round the mower deck. Just tweak till it fits.

Cut the overlap off:

Weld the resultant gaps up.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,519

- Location

- Sevenoaks, UK

What thickness steel is that Bob?

It was me and I used 2mm mild.

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

Sorry, got confused - thanks.It was me and I used 2mm mild.

I have repaired those exact model 3 rotor Countax deck, 38 or 42 IBS s plenty of times now, not too bad if you take a big picture approach.

1 Cut out the centre section that houses all the shafts etc, this preserves all the belt and blade spacing and cover mounting.

2 Cut from 16g or 1.5mm stainless steel the complete deck profile, weld 80mm wide stainless strip around it to replicate the side skirt, trim around the bottom with 10mm stainless rod, this avoids having to form any re-curved edge and is way tougher when hitting rocks or stumps. your choice as to whether you fit the curved grass deflectors underneath.

3 Position original top plate, tack, drill and weld back on, make sure to avoid the plate warping, or you get weird cutting problems.

1 Cut out the centre section that houses all the shafts etc, this preserves all the belt and blade spacing and cover mounting.

2 Cut from 16g or 1.5mm stainless steel the complete deck profile, weld 80mm wide stainless strip around it to replicate the side skirt, trim around the bottom with 10mm stainless rod, this avoids having to form any re-curved edge and is way tougher when hitting rocks or stumps. your choice as to whether you fit the curved grass deflectors underneath.

3 Position original top plate, tack, drill and weld back on, make sure to avoid the plate warping, or you get weird cutting problems.

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

Ok I finally got round to this project. I got the top plate, the bottom lip, and all the attachment brackets laser-cut out of 4mm stainless (yep that's right - way thicker than I needed really) from a dxf I had done. I also got some 3mm plate cut into the right width to form the skirt.

Bending the skirt to the right curves proved a challenge - I eventually ended up making some plywood formers and g-clamping the skirts strips around. Then I did it again with some undersized formers as I hadn't reckoned how much the steel would spring back, doh!

Then I welded it all up.

Pictures to follow, when I work out how to post them!

Bending the skirt to the right curves proved a challenge - I eventually ended up making some plywood formers and g-clamping the skirts strips around. Then I did it again with some undersized formers as I hadn't reckoned how much the steel would spring back, doh!

Then I welded it all up.

Pictures to follow, when I work out how to post them!

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

Top plate with skirts and lower lips welded on:

Slight error in cutting the skirt lengths that left a gap, I had to fill later!

Slight error in cutting the skirt lengths that left a gap, I had to fill later!

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

Fitting the internal deflectors:

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

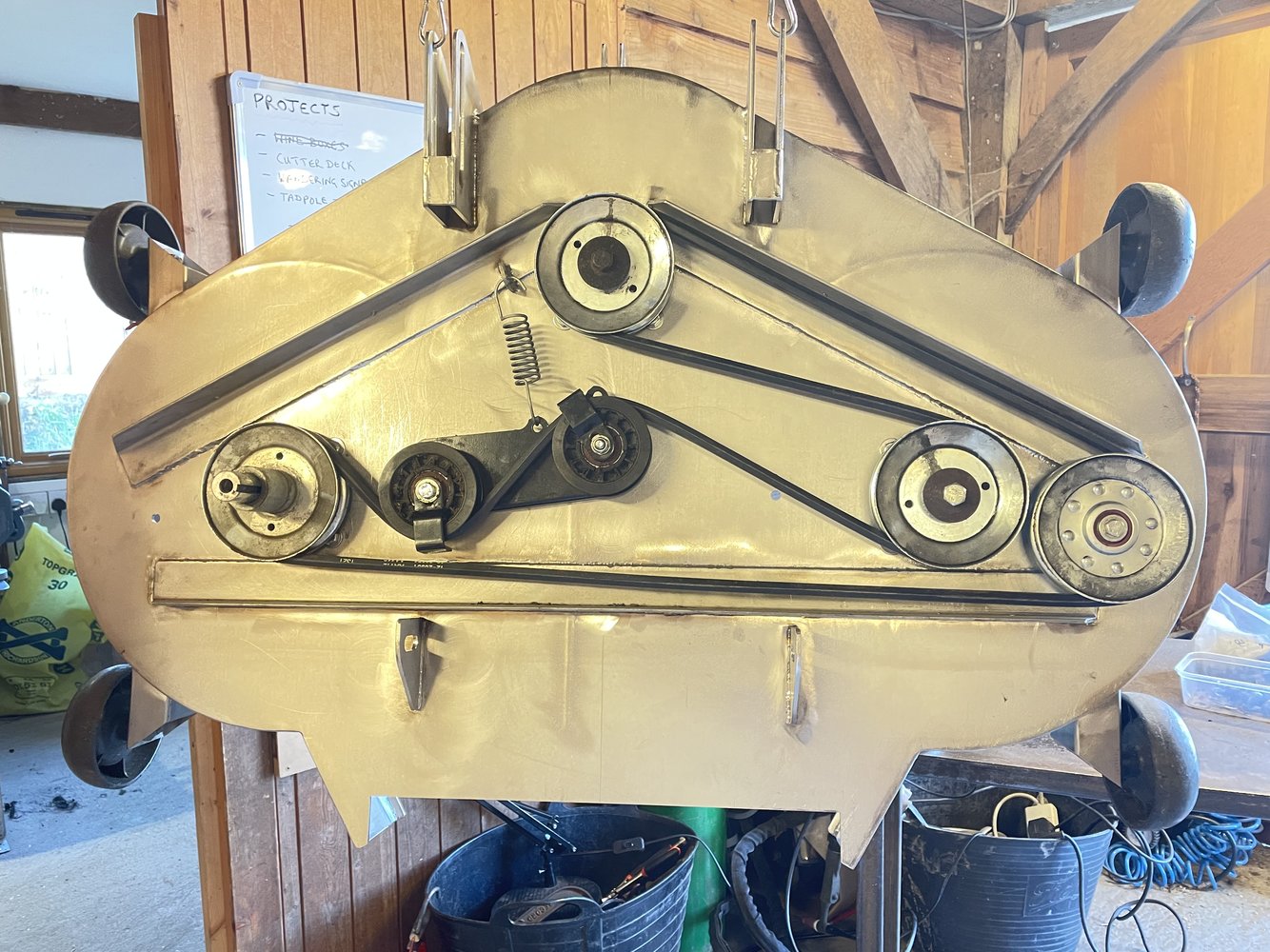

Lifting brackets and belt cover fixing points:

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

Finished deck with rotors, belts, blades and wheels refitted.

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

It fits!...

And works! First cut of some very long wet grass - all fine....

And works! First cut of some very long wet grass - all fine....

Benpointer

Member

- Messages

- 49

- Location

- Dorset, UK

Issues I had?

Bending 3mm steel by hand was hard work.

The 4mm top plate still warped despite me taking what I thought was enough care to clamp and tack first. I think once I got started with the seam welding the sides on I got a bit carried away. The warping is not too bad, just meant that the central rotor dropped by 5-6mm. I was able to compensate by skimming 5mm off the rotor face plate in my lathe - still plenty of meat left on it so no issues really, apart from the fact that I'd need some packing to use the skimmed rotor with a factory deck shell... but this current one is never rusting (hopefully) so it's not a worry.

Oh, and the new deck is twice the weight of the old one (44kg fully fitted now!) But the rise and fall is still fine and I think the mower can cope fine with a heavy deck (the Countax long grass deck looks to weigh a ton). These Countax mowers are solidly made. Nevertheless, if I were doing it again (I won't be) I'd use 2 or 3mm s/s for the top plate.

Bending 3mm steel by hand was hard work.

The 4mm top plate still warped despite me taking what I thought was enough care to clamp and tack first. I think once I got started with the seam welding the sides on I got a bit carried away. The warping is not too bad, just meant that the central rotor dropped by 5-6mm. I was able to compensate by skimming 5mm off the rotor face plate in my lathe - still plenty of meat left on it so no issues really, apart from the fact that I'd need some packing to use the skimmed rotor with a factory deck shell... but this current one is never rusting (hopefully) so it's not a worry.

Oh, and the new deck is twice the weight of the old one (44kg fully fitted now!) But the rise and fall is still fine and I think the mower can cope fine with a heavy deck (the Countax long grass deck looks to weigh a ton). These Countax mowers are solidly made. Nevertheless, if I were doing it again (I won't be) I'd use 2 or 3mm s/s for the top plate.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,491

- Location

- Near to Cross Hands Llanelli SouthWales GB

I had one of the almost flat spinning lawn sprinklers set o a piece of blue plastic water pipe used on a concrete wash pad area for under washing things , I used drive over the hose , pull it under the deck turn it on & carefully wash underneath the deck over a few minutes duration , after each use then drive it into the dry airy shed where it lived .Clean grass out regularly, apply corrosion inhibiting compound.

That is all.

IIRC in the early 1960's Hayter used to do an aluminium deck for a lot of their mowers but they suffered from corrosion due to dissimilar metals being used . I've often wondered why no- one makes a quality fibre glass deck instead . I'm too old to bother now ( 71 yrsold ) I've downsized from 2 acres to two tiny pocket handkerchief lawns & a bungalow .Why don't they make them of aluminium, then it'd be a job for lifesuppose they'd not sell enough lawnmowers then.

I have a brand new mountfield sitting in the garage, haven't had it on the lawn yet and just know as soon as its used the decay will start, have to make sure I clean it properly and use some sort of rust inhibitor on it over the winter. I have had only 2 petrol lawnmowers over the last 24 years, normal self propelled jobs, 1st was well patched and welded then the engine seized. Bought a new one which must be 10+ years old now, also patched and repaired but still going strong

I had a Mountfield 42 inch cut with a grass brush collector on the back some 22 years ago .. T'was lovely machine but at £1200 or so was very wary of letting a grass build up underneath take place as I'd seen far too many wrecks com into the plant hire for repairs

Could you de-paint then treat the shroud in phosphoric acid put on a cold zinc spray coat then do a 4 mm thick skin the underside of fibre glass then use wide head non reactive plastic pop rivets to hold it in place ?

Edward Teach

pre-moderated

- Messages

- 997

- Location

- South West England

Excellent work,

A proper job,

Well done Sir

A proper job,

Well done Sir

angellonewolf

Member

- Messages

- 8,730

- Location

- bristol england

top job