You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have fixed today

- Thread starter qwakers

- Start date

@MattF because the milling machine motor was literally an inch clear of the original roof, so I’ve added some extra height at the back for the machine, some storage and just general useable space. The area above the garage door when it is open is wasted because it’s inaccessible so no point having the extra space there. Also as you say, water would run off the back and pool on the pad running under the rear wall into the garage, that should mitigate some of that

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 19,858

- Location

- Going Away.

Not sure if it is fixed or made today.

A friend is in needs of a bench polisher.

I had a spare bench grinder.

So, when I was away I found out the specs and ordered two mop spindles.

But they did not fit, Oh well.

Managed to get some that fitted.

Two mops.

The RHS spindle had a small burr, but that was soon removed.

A friend is in needs of a bench polisher.

I had a spare bench grinder.

So, when I was away I found out the specs and ordered two mop spindles.

But they did not fit, Oh well.

Managed to get some that fitted.

Two mops.

The RHS spindle had a small burr, but that was soon removed.

Norsk

Member

- Messages

- 547

- Location

- Norway

Sergei Slovenija

Member

- Messages

- 1,267

- Location

- Slovenija Ljubljana

I remembered and found in the pile of “metal just in case” the remains of such a device. I removed the extra gears. When the long rusty bolt is rotated, the thick central bushing made of brass pushes the 10 mm stainless steel rod 50 mm back and forth. The bushing has thrust roller bearings (!) and an internal thread M12*1.75. I'll try to make an analogue of micrometric feed. By tilting the angle grinder up to 45 degrees, I change the distance from the abrasive disc to the part. One turn of the screw gives 0.5 mm of extension of the rod. Work for TIG. PS - I made a little mistake with the posting thread.I made a machine/jig for a hell of a job to sand deep and even grooves.

A cross vice handles the X and Y coordinates; for the Z coordinate, I will sequentially place plates under the clamp with the part.

As we increase the height of the floor with the part, we cut deeper.

Anything you can think of to avoid buying a milling machine, oh yes.

View attachment 424057 View attachment 424058 View attachment 424059

qwakers

Member

- Messages

- 2,202

- Location

- cornwall, united kingdom

the wire on my makita charger got ran over (i would assume) and had stopped working unless the wire was held at just the right angle. i had some flat 2 core knocking around from a old laptop charger, so i used that...

shame its white but ho hum, works again.

shame its white but ho hum, works again.

octo0072000

Member

- Messages

- 6,019

- Location

- south yorks

£550 for a solenoid i hope thats a mistakeMy tipping trailer wouldn't tip.

Turns out the solenoid had broken through the housing. Called the Norwegian dealer for a new one,£550!

Ordered one from ebay and bodged the housing with to courses of epoxy,some plastic and a mig wire hoop.

Will hopefully last until the new one arrives.

View attachment 425011 View attachment 425012 View attachment 425013

Norsk

Member

- Messages

- 547

- Location

- Norway

No its not I am afraid.£550 for a solenoid i hope thats a mistake

I used to pay £200 for solenoids on woodchipper valve blocks untill I learned that they were a £20 item of Ebay.

Some companies have the monopoly here and they really extract the Urine

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 19,858

- Location

- Going Away.

I was given a load of those small hand tools.

So I cleaned them up.

Fitted them to a care home to fill up some old spaces.

lchris21

Member

- Messages

- 1,973

- Location

- South Wales

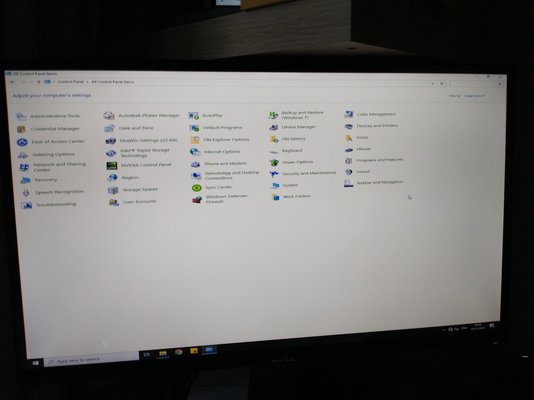

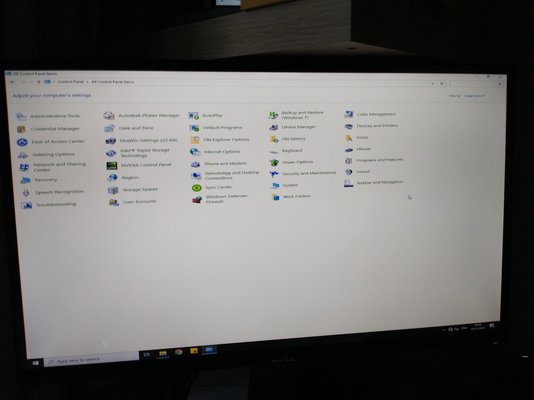

...on a scale of 1 to 10. My IT skills languish around the 2-3 mark, with my IT patience level even lower

So I'm pretty chuffed to have rescued a dead desktop PC I use in the garage. It was in a death spiral of blue and black screens...Even asked my IT support neighbour who advised to bin it ....( civil servants eh!).

....( civil servants eh!).

The wonders of YouTube and a £3.50 cable, a jump start off a working pc and several hours of it doing it's thing and hey presto it lives a bit longer

So I'm pretty chuffed to have rescued a dead desktop PC I use in the garage. It was in a death spiral of blue and black screens...Even asked my IT support neighbour who advised to bin it

....( civil servants eh!).

....( civil servants eh!).The wonders of YouTube and a £3.50 cable, a jump start off a working pc and several hours of it doing it's thing and hey presto it lives a bit longer

Last edited:

lchris21

Member

- Messages

- 1,973

- Location

- South Wales

do you do all your won plating? looks really goodContinued.

View attachment 424725View attachment 424727

View attachment 424730

View attachment 424728

View attachment 424733

View attachment 424734

And here's how it arrived to me...

Not all done yet. Few things left to go back together

View attachment 424726

View attachment 424729

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,134

- Location

- France, Brittany.

Well not fixed, but started on another engine change today.

4.5 hours later it was out, no rushing, will take longer to clean and repaint the bilge.

Seperated the gearbox once the propshaft was seperated from flexible coupling, easier to get the engine out.

That'll get kept as a spare good engine, in case one dies. There's a brand new one waiting to go in.

4.5 hours later it was out, no rushing, will take longer to clean and repaint the bilge.

Seperated the gearbox once the propshaft was seperated from flexible coupling, easier to get the engine out.

That'll get kept as a spare good engine, in case one dies. There's a brand new one waiting to go in.

Blobber

Member

- Messages

- 2,812

- Location

- lincolnshire

Doesnt look that old, nice and clean for a diseaselWell not fixed, but started on another engine change today.

View attachment 425388

4.5 hours later it was out, no rushing, will take longer to clean and repaint the bilge.

Seperated the gearbox once the propshaft was seperated from flexible coupling, easier to get the engine out.

View attachment 425392

That'll get kept as a spare good engine, in case one dies. There's a brand new one waiting to go in.

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 19,858

- Location

- Going Away.

Nice little job tonight.

This odd Oil Lamp came my way.

It was just missing a wick. It also needed a service and a clean.

The lamp was striped and cleaned. The metal was given a polish with my my mix of oil and wax.

The wick gears was cleaned of the old oil and fuel. With just hot water and washing powder.

The new wick was cut a bit longer than needed. Then a slight angle is cut the make running the wick in easier.

Clear lamp oil, food dye and menthol mix.

First light. Turns out the original wick was rotten, so I fitted another new wick.

The chimney was cleaned and the fingers "tweaked" to hold it correctly.

This odd Oil Lamp came my way.

It was just missing a wick. It also needed a service and a clean.

The lamp was striped and cleaned. The metal was given a polish with my my mix of oil and wax.

The wick gears was cleaned of the old oil and fuel. With just hot water and washing powder.

The new wick was cut a bit longer than needed. Then a slight angle is cut the make running the wick in easier.

Clear lamp oil, food dye and menthol mix.

First light. Turns out the original wick was rotten, so I fitted another new wick.

The chimney was cleaned and the fingers "tweaked" to hold it correctly.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,134

- Location

- France, Brittany.

That was a retired engine, like this one now is again, that I slung in, in 2019, after the original engine died. We'd been meaning to change it, but between covid and Kubota having issues in the supply chain, its taken a while.Doesnt look that old, nice and clean for a diseasel

It did 4 years, completely hassle free, it's a good spare engine in case of emergencies, enjoying its second retirement. Apart from 400 hour oil changes, generally, they don't go wrong, we change all the rubber coolant pipes every few years, there as good as small marine engine get frankly.

Yeah, over 20 years we've had some issues, but to be expected.

GG1

Member

- Messages

- 142

- Location

- Dunblane, Scotland

Did you find all the genies annoying?The lamp was striped and cleaned. The metal was given a polish with my my mix of oil and wax.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,134

- Location

- France, Brittany.

No, he wishes for more lamps, and mammod steam toys.Did you find all the genies annoying?

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 19,858

- Location

- Going Away.

And less NorbertsNo, he wishes for more lamps, and mammod steam toys.

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 19,858

- Location

- Going Away.

Not got a Mamod for days now.No, he wishes for more lamps, and mammod steam toys.