Mine did the same - I might have been slightly more gentle on the squeezing back of the crimp thoughToday I fixed the wipers on my Alfa 159.

The driver's side was juddering and on closer inspection I noticed the arm was hitting the bonnet.

View attachment 437792

I suspected the spindle was worn so I took the motor and linkage off for a look.

The bulkhead drains were blocked so there was a bit of a pond ecosystem going on.

View attachment 437793

Anyway the spindles and ball joints were pretty much perfect, however the plastic spindles are crimped into the linkage tubes and the drivers side had worked itself loose.

No problem though I, I'll just tighten the crimp but on the first squeeze I heard a crack and the plastic insert let go completely.

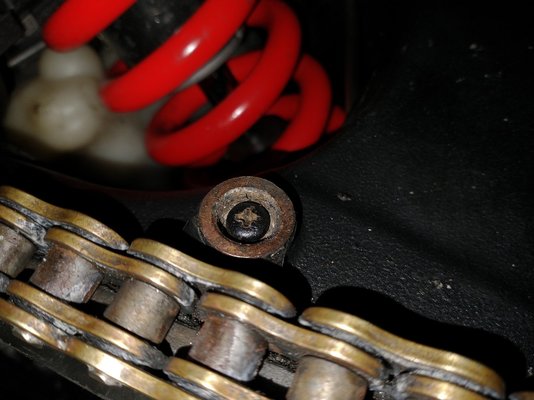

View attachment 437797

Oh bother said I, what to do.

New wiper linkages are almost £400 from Alfa, pattern parts and secondhand linkages are available, but I thought I'd have a go at repairing it (as you do)

I had a look in the scrap bin and found suitable material.

First job was to measure everything up then turn off the broken stub on the spindle.

View attachment 437799

Then turn some pipe to fit over the reduced spindle, a steel stub and replacement section of pipe for the linkage frame.

I then welded them together.

View attachment 437800

I cut off the damage section of the linkage frame and welded in a short section of pipe.

View attachment 437803

Tacked it up and had a trial fit.

It looked ok and I was doing to weld the stub into the pipe, but then I thought it might be useful to have some adjustment so made a clamp to hold the stub inside the tube.

View attachment 437804

After another trial fit I used Araldite to glue the spindle into the steel sleeve.

View attachment 437805

With the glue dry I was able to reinstall the linkage.

Slackening the clamp allows the spindle (and so the wiper arm and blade) to be rotated so that the wiper blade sits perpendicular to the screen.

Normally the wiper is just twisted to set the blade angle but with this I can make sure the wiper arm clears the bonnet as well.

View attachment 437811

With a bit of adjusting I've got the driver's side working perfectly, plenty of clearance and a good quiet wipe.

The passenger's side was always good so I'll call this a fix.

I still needs to paint the wiper arms and the linkage repairs but that can wait for a day or two.

A lot for work fixing a part that's available, however I do like fixing stuff and I'd say this is possibly an improvement.

I drilled and pinned it too. I see you already have the bigger washers over the rubber mounting bushes to stop it twisting away from the screen - took me a while to work out why my drivers side wiper didn't wipe the centre 6" of the blade - whole mech had tipped away from the screen and the arm had bottomed out on it's downward travel, so no actual spring pressure to hold the blade on the screen.

I drilled and pinned it too. I see you already have the bigger washers over the rubber mounting bushes to stop it twisting away from the screen - took me a while to work out why my drivers side wiper didn't wipe the centre 6" of the blade - whole mech had tipped away from the screen and the arm had bottomed out on it's downward travel, so no actual spring pressure to hold the blade on the screen.Had to remove the whole thing to get to the bleed screws on the brake master cylinder around the V6 engine - and still couldn't fget decent access. Seems a bit excessive to remove the engine just to be able to bleed the brakes!

Still dislike the fact it has three auto settings, not three settings for intermittent - always seems to be going like the clappers on a dry screen, or resting in a downpour.