You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

roblane65

Member

- Messages

- 2,200

- Location

- Newcastle UK

Yesterday I made the scrap bag a little heavier

then today I thought I'd have a go at sorting the garage didnt get far

all the reclaimed f/boards are for a top for me sis's dog cage

gave up in the end and just chopped up all the wood off cuts for kindlin / fire wood

water tank came in handy though

I'm off tomorrow so I'll have another go at the garage then .

then today I thought I'd have a go at sorting the garage didnt get far

all the reclaimed f/boards are for a top for me sis's dog cage

gave up in the end and just chopped up all the wood off cuts for kindlin / fire wood

water tank came in handy though

I'm off tomorrow so I'll have another go at the garage then .

Kram

Member

- Messages

- 7,417

- Location

- Sussex

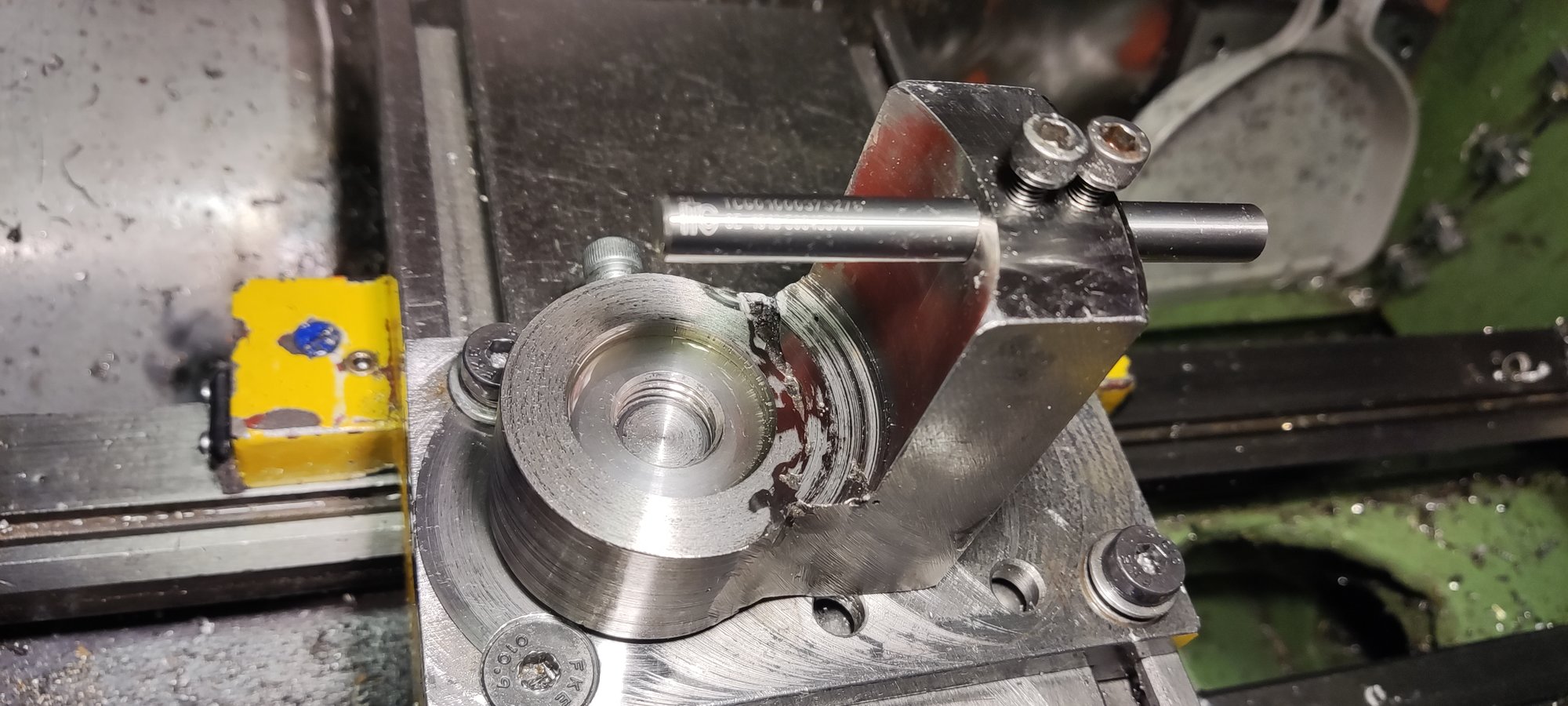

The radius/ball turner. Not finished but enough to test.

Couldnt fit a bigger bar as too near top, 8mm appears to work. I think I will bore it out to 25 or 32mm and weld a bit on so I can use larger bars. If I should want to do large concave radiuses there would be a fair stickout.

I then discovered my 8mm boring bar has the insert pocket above centre, so it would never work well for this. The insert off to the side also makes it unsuitable, but tried it anyway.

I will make a dcmt insert boring bar for this with the point in the centre.

Found a cheap countersink and a short end of en3 rubbish steel. Actually works bloody well.

I will need to remove the corners from the upright which could be a job for the big facemill.

Couldnt fit a bigger bar as too near top, 8mm appears to work. I think I will bore it out to 25 or 32mm and weld a bit on so I can use larger bars. If I should want to do large concave radiuses there would be a fair stickout.

I then discovered my 8mm boring bar has the insert pocket above centre, so it would never work well for this. The insert off to the side also makes it unsuitable, but tried it anyway.

I will make a dcmt insert boring bar for this with the point in the centre.

Found a cheap countersink and a short end of en3 rubbish steel. Actually works bloody well.

I will need to remove the corners from the upright which could be a job for the big facemill.

selectedgrub

Member

- Messages

- 3,346

- Location

- New Zealand

They go for stupid money down herePut the woodburner on marketface and it had sold in ten minutes

selectedgrub

Member

- Messages

- 3,346

- Location

- New Zealand

DAPPH

as dyslexik as I'm daft

- Messages

- 7,351

- Location

- Near to Cross Hands Llanelli SouthWales GB

Thousand of other members might like to know what the cabinet is for . I'm guessing it's for storing soft soap for Welshmen , a sporran repair kit for them up north or a medicine cabinet for decrepit old English gentlemen .

It might also be a conversation piece .

It might also be a conversation piece .

It might also be a conversation piece .

It might also be a conversation piece .As a general bodger I used every clamp I had there to wood glue the ply edge.You need some more clamps.

Wood clamps, Metalwork Kennedy Clamps, G Clamps & Welding Clamps are all in there

.

.It looks like Edward Scissorhands' place!

Kram

Member

- Messages

- 7,417

- Location

- Sussex

More details please, what is the rest of the setup and what gear are you making? Something I will try eventually.A brace for the toolpost stud for when hobbling. It was far too flexible the first couple of attempts.

View attachment 438709

DAPPH

as dyslexik as I'm daft

- Messages

- 7,351

- Location

- Near to Cross Hands Llanelli SouthWales GB

Could you when removing theb outer edges actually make is so th cutting bit comes out of a triangle point to give you a bigger max working range Will it have an extension handle fitted ? What range of radius will the balls be <The radius/ball turner. Not finished but enough to test.

Couldnt fit a bigger bar as too near top, 8mm appears to work. I think I will bore it out to 25 or 32mm and weld a bit on so I can use larger bars. If I should want to do large concave radiuses there would be a fair stickout.

View attachment 438568

I then discovered my 8mm boring bar has the insert pocket above centre, so it would never work well for this. The insert off to the side also makes it unsuitable, but tried it anyway.

View attachment 438570

I will make a dcmt insert boring bar for this with the point in the centre.

Found a cheap countersink and a short end of en3 rubbish steel. Actually works bloody well.

View attachment 438571

I will need to remove the corners from the upright which could be a job for the big facemill.

A hanging curtain from the roof on a rail would have done just as well in a fraction of the time , plus the curtain moves to accommodate the contortions when cleaning up and allows a bit of through view to the back doors when drawn back , it doesn't vibrate like a drum either .Today I have faffed about working out how to build a square wall in my decidedly un-square van for the Thunderbox.

I'm no carpenter & that's my excuse for taking all day to build the sodding thing

View attachment 438683 View attachment 438684

You can't hang/build overhead lockers off a Curtain though Dapph, plus my 2-seater sofa box will be built off this wall as well.A hanging curtain from the roof on a rail would have done just as well in a fraction of the time , plus the curtain moves to accommodate the contortions when cleaning up and allows a bit of through view to the back doors when drawn back , it doesn't vibrate like a drum either .

The loo cubicle also doubles as a cloakroom & extra storage in transit to save clutter - and we prefer the feeling of a tad more privacy for the privy lol (even if it is more illusion than actual).

Kram

Member

- Messages

- 7,417

- Location

- Sussex

Yes that is the plan I am going to mill the tube face flat and from the OD of the tube to the back corner, so somewhere around 60 degrees I imagine. It would have been much simpler if I started with 30mm thick plate and bored a hole to weld in a 50mm bar as the upright.Could you when removing theb outer edges actually make is so th cutting bit comes out of a triangle point to give you a bigger max working range Will it have an extension handle fitted ? What range of radius will the balls be <

Range it has enough clearance and should be able to do 100mm concave to 60mm diameter balls.

iNf

Member

- Messages

- 456

- Location

- Hereford, England

I'll start another thread, it's a bit long winded to clutter up this oneMore details please, what is the rest of the setup and what gear are you making? Something I will try eventually.