You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

badabec

Member

- Messages

- 2,012

- Location

- Essex UK

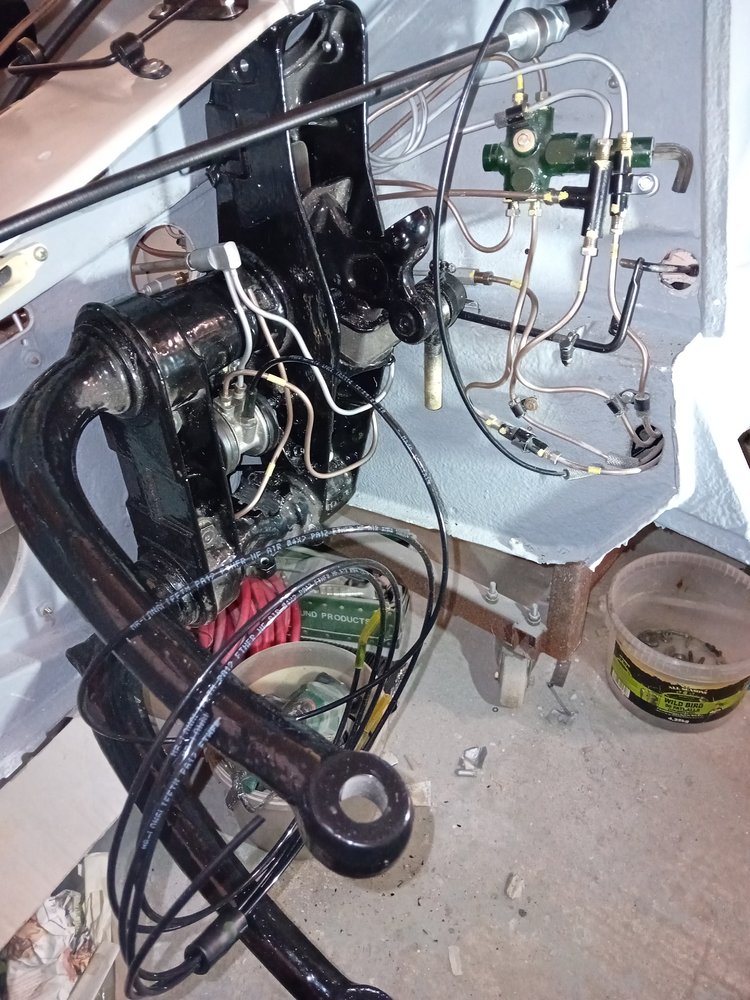

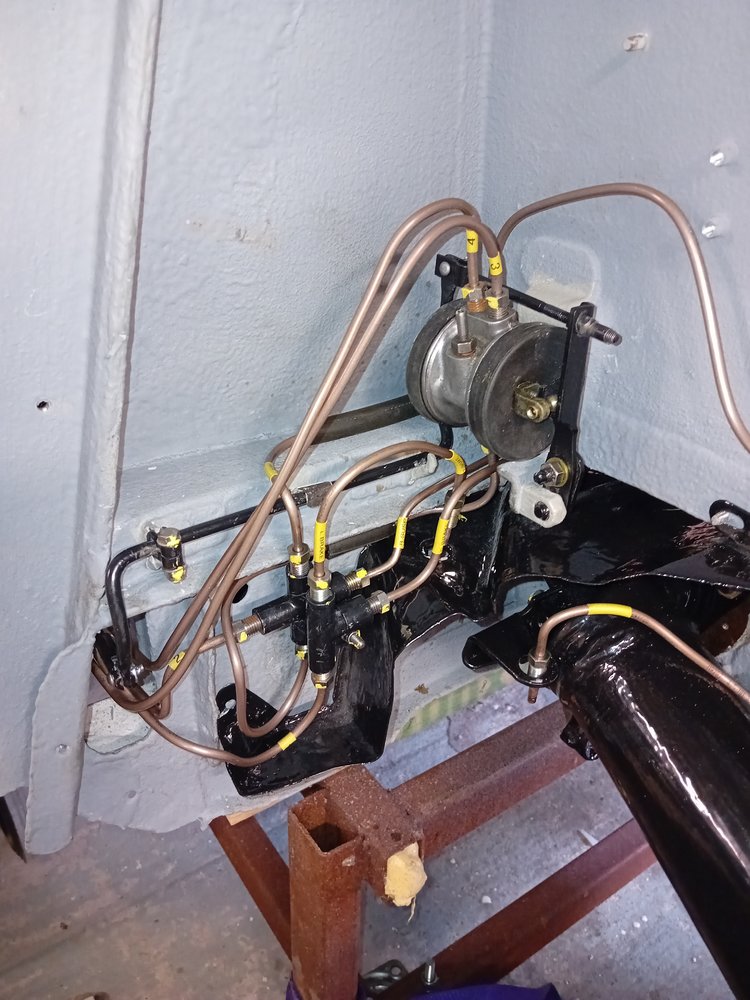

I finished the re-plumbing of the Citroen DS suspension today. It has taken several weeks. My thumbs are sore from bending the Kunifer pipes. The pipes need a special flaring tool and dies. It puts a bulge about 12mm from the end and also reduces the diameter of the tube for the last 2mm. A rubber seal pushes onto the pipe. With the pipe properly installed, the flare nut doesn't have to be apprentice tight. As the hydraulic pressure builds up, the rubber seal deforms and improves the seal.Now I have to fit the return pipes, these are nylon, low pressure and return any leaking hydraulic fluid back to the reservoir.

I finished the re-plumbing of the Citroen DS suspension today. It has taken several weeks. My thumbs are sore from bending the Kunifer pipes. The pipes need a special flaring tool and dies. It puts a bulge about 12mm from the end and also reduces the diameter of the tube for the last 2mm. A rubber seal pushes onto the pipe. With the pipe properly installed, the flare nut doesn't have to be apprentice tight. As the hydraulic pressure builds up, the rubber seal deforms and improves the seal.Now I have to fit the return pipes, these are nylon, low pressure and return any leaking hydraulic fluid back to the reservoir.

View attachment 437818View attachment 437821

How many times did you forget to slide the nut onto the pipe before making the flare?

DAPPH

as dyslexik as I'm daft

- Messages

- 7,347

- Location

- Near to Cross Hands Llanelli SouthWales GB

Those flared return pipes on the plastic Citroen suspension tubes were the bane of our lives they always kept coming apart if we hit a hump or sleeping policeman hard . We had three Citroens at the timeI finished the re-plumbing of the Citroen DS suspension today. It has taken several weeks. My thumbs are sore from bending the Kunifer pipes. The pipes need a special flaring tool and dies. It puts a bulge about 12mm from the end and also reduces the diameter of the tube for the last 2mm. A rubber seal pushes onto the pipe. With the pipe properly installed, the flare nut doesn't have to be apprentice tight. As the hydraulic pressure builds up, the rubber seal deforms and improves the seal.Now I have to fit the return pipes, these are nylon, low pressure and return any leaking hydraulic fluid back to the reservoir.

View attachment 437818View attachment 437821

One particular evening out in my BX 19 GTD turbo , me in evening dress & Alison in an evening gown we happened to cross a slightly sunken rail crossing at 60 mph near Pertnal Bedfordshire almost 50 miles from home at 01.30 ish . The resultant shock blew off the rear suspension pipe connectors leaving the car head up shining the dipped head light to the stars and blinding any poor sod coming towards us .

I solve it the next day by using the crushable ovalid rings you use on rubber hoses on gas pipes on each connector tube , then did the other two cars as well .

DAPPH

as dyslexik as I'm daft

- Messages

- 7,347

- Location

- Near to Cross Hands Llanelli SouthWales GB

I have made my lathe a working lathe again last night , I've fitted two new turned up cross shaft bearing holders fitted with 3/4 " high speed bearings either side of the blocks . They replace the made in 1943 well neglected & worm phosphor bronze bearings .

It also got a turned down for a gentle sliding fit new 3/4 " cross shaft as the original one was deeply scored through lack of care & lube by the PO .

All thanks to Fizzy ,as my tiny 10" throw lathe does not at present have the capability to turn big chunks of steel in the chuck unsupported as the jaws are only an inch or so deep till you hit the back plate .

We also used his super duper very accurate Colchester lathe to abraid the new cross shaft by a few microns from a 3/4" precision drill rod down to the sliding fit in the 3/4 " id bearings & used his CNC mill in milling the bearing carriers mounting points .

It also got a turned down for a gentle sliding fit new 3/4 " cross shaft as the original one was deeply scored through lack of care & lube by the PO .

All thanks to Fizzy ,as my tiny 10" throw lathe does not at present have the capability to turn big chunks of steel in the chuck unsupported as the jaws are only an inch or so deep till you hit the back plate .

We also used his super duper very accurate Colchester lathe to abraid the new cross shaft by a few microns from a 3/4" precision drill rod down to the sliding fit in the 3/4 " id bearings & used his CNC mill in milling the bearing carriers mounting points .

DAPPH

as dyslexik as I'm daft

- Messages

- 7,347

- Location

- Near to Cross Hands Llanelli SouthWales GB

Could you not just bolt on a U shaped counter weight in the two free holes so it lies inside the chuck jaw free space ?My lathe does not like unbalanced turning. Max of 300rpm set up like this. I may have to drilla dn tap chuck to allow counter weights next time.

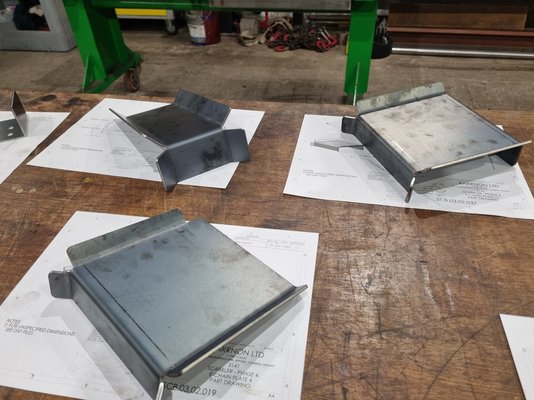

View attachment 437822

View attachment 437823

I have used stud lock on the threads. Abiut to start turning the pivot.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,131

- Location

- Sevenoaks, UK

I may have to drill and tap chuck to allow counter weights next time.

How about another bit of that plate, cut to a trouser shim shape and screwed onto the other plate?

addjunkie

Member

- Messages

- 12,934

- Location

- Northumberland. Reet oot in the sticks

Bigger lathe wouldnt have noticed the imbalance.My lathe does not like unbalanced turning. Max of 300rpm set up like this. I may have to drilla dn tap chuck to allow counter weights next time.

View attachment 437822

View attachment 437823

I have used stud lock on the threads. Abiut to start turning the pivot.

DennisCA

Member

- Messages

- 1,989

- Location

- Finland

Pie cuts are cool and easy to make with a bandsaw. But I don't have a bandsaw, just an angle grinder.

So I made a 1:1 template in fusion 360, I needed to print this on two A4s , it's a 22.5 degree template.

That feeling when the template matches the pipe perfectly and both edges line up...

Made a few of them by now, but need a couple more before everything lines up, I might redo the short segment for a longer drop straight down first.

So I made a 1:1 template in fusion 360, I needed to print this on two A4s , it's a 22.5 degree template.

That feeling when the template matches the pipe perfectly and both edges line up...

Made a few of them by now, but need a couple more before everything lines up, I might redo the short segment for a longer drop straight down first.

Sergei Slovenija

Member

- Messages

- 1,267

- Location

- Slovenija Ljubljana

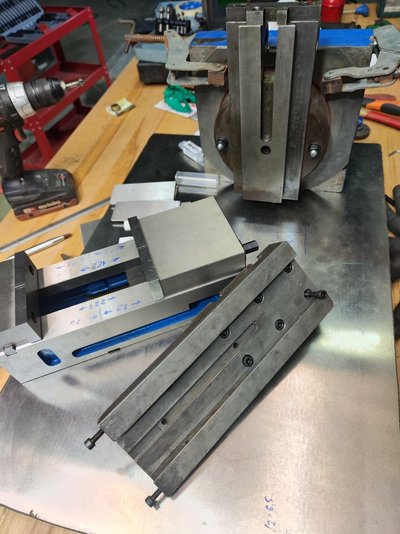

in progress.Marking the holes for connecting the vice and part of the cross lathe support. 7 pies M6 imbus bolts should be enough.

View attachment 437777 View attachment 437779

Kram

Member

- Messages

- 7,417

- Location

- Sussex

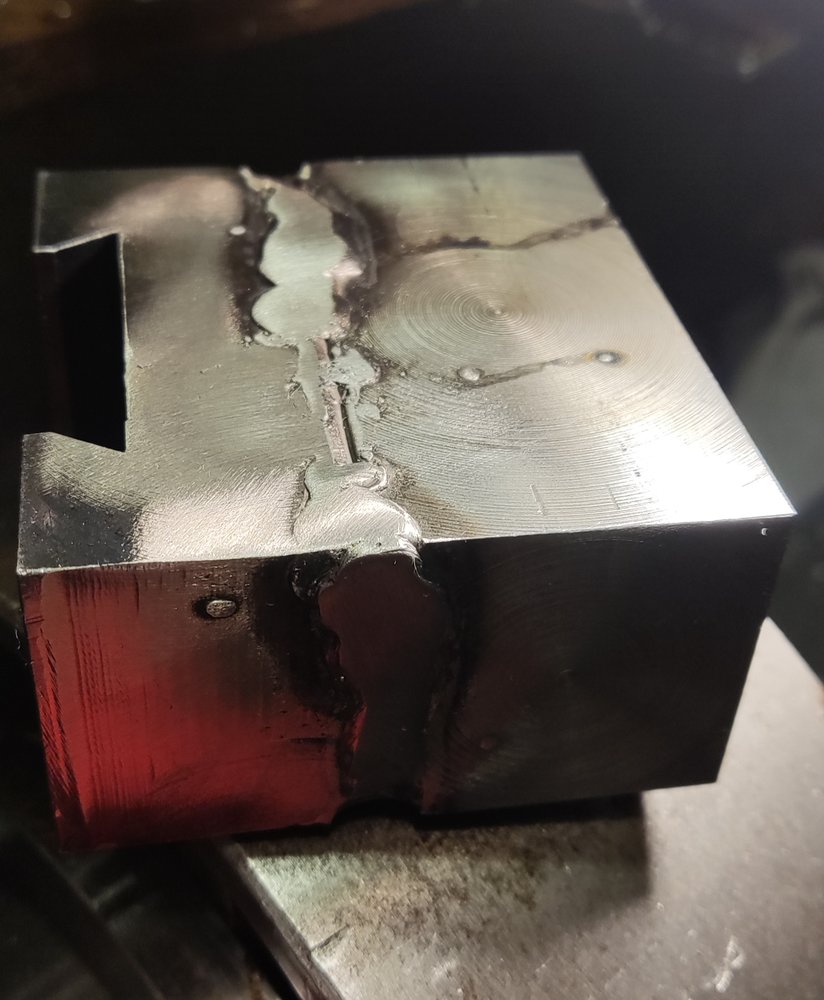

Bored tube for perfect 29.98mm fit on a 29.98mm OD.

Next I want to weld a bit of bar to the OD but needs a radius for easier welding. Stuck it to a spare tool holder to mill it on lathe with boring head. I wanted it well stuck but did not consider how easy it will be to remove after...

I hadnt used stick for ages, the 3.2mm 7018 rods were hard to light. Used 160A as its quite a thick lump.

Next I want to weld a bit of bar to the OD but needs a radius for easier welding. Stuck it to a spare tool holder to mill it on lathe with boring head. I wanted it well stuck but did not consider how easy it will be to remove after...

I hadnt used stick for ages, the 3.2mm 7018 rods were hard to light. Used 160A as its quite a thick lump.

DennisCA

Member

- Messages

- 1,989

- Location

- Finland

OK I've completed the welding and made my first fire. No smoke leaks!

You've heard of MIG like TIG, I present MIG like Stick:

Still need to disassemble and paint it with proper paint, and maybe clean up behind the stove while I am at it. And fit the flue gas thermometer so I can see what the difference is from before. It does put out a lot of heat I can tell just by standing near it.

You've heard of MIG like TIG, I present MIG like Stick:

Still need to disassemble and paint it with proper paint, and maybe clean up behind the stove while I am at it. And fit the flue gas thermometer so I can see what the difference is from before. It does put out a lot of heat I can tell just by standing near it.

Barking Mat

Cuddler of hedgehogs.

- Messages

- 13,154

- Location

- France, Brittany.

I'm intrigued by the smoke stack 'u' pipe and how will you rod the smaller pipes.OK I've completed the welding and made my first fire. No smoke leaks!

You've heard of MIG like TIG, I present MIG like Stick:

Still need to disassemble and paint it with proper paint, and maybe clean up behind the stove while I am at it. And fit the flue gas thermometer so I can see what the difference is from before. It does put out a lot of heat I can tell just by standing near it.

Hood

I am obsessed.

- Messages

- 17,462

- Location

- Carnoustie, Scotland

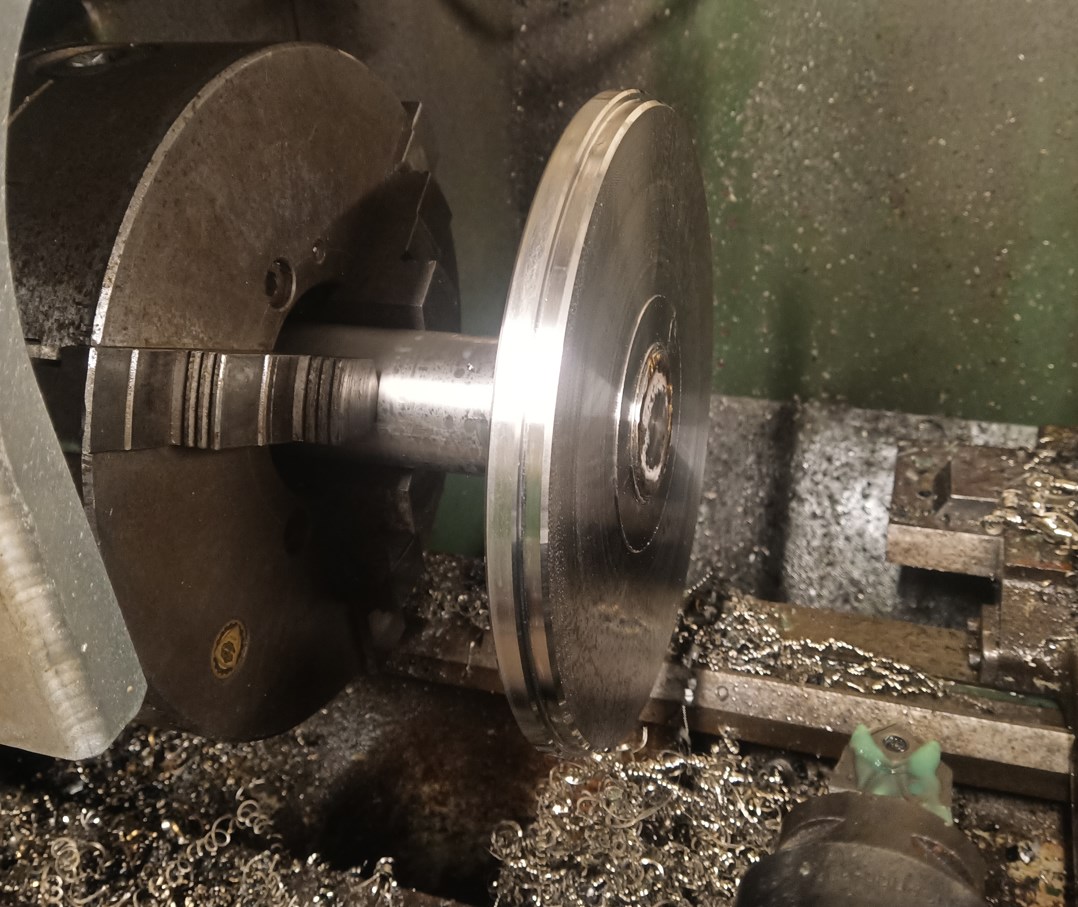

Yesterday I bored out some 250mm dia x 16mm thick plates to 45mm ID. Then turned down some 50mm dia to 45mm and pressed them together and welded.

Today I turned the OD down to 219mm then a step down to 112mm

Pressed them into some 8" NB pipe and welded in place.

Flipped around in my bandsaw bench and did the other side.

Today I turned the OD down to 219mm then a step down to 112mm

Pressed them into some 8" NB pipe and welded in place.

Flipped around in my bandsaw bench and did the other side.

DennisCA

Member

- Messages

- 1,989

- Location

- Finland

I'm intrigued by the smoke stack 'u' pipe and how will you rod the smaller pipes.

I assume that means cleaning them? I dunno I might pull out the stove and disassemble it, or make a cleaning hatch on the top side somewhere so I can clean it from above.

Hood

I am obsessed.

- Messages

- 17,462

- Location

- Carnoustie, Scotland

Nah, don't have one of themWheelie bar for the Transalp?