You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Brad93

Member

- Messages

- 18,520

- Location

- Essex, United Kingdom

Dough mixerSheared at the bearing? That took some force! Whats it for?

Or simply an uneven, oscillating load over time . . . fatigue just as good as exceeding maximum load.Sheared at the bearing? That took some force! Whats it for?

Brad93

Member

- Messages

- 18,520

- Location

- Essex, United Kingdom

That’s what it was.Or simply an uneven, oscillating load over time . . . fatigue just as good as exceeding maximum load.

Misalignment too - due to crap design and trying to mount three bearings on a shaft in close proximity, one of our machines bust a 5" shaft in a similar fashion.That’s what it was.

I've had to warn my boss(es) about a conveyor they've bought from Holland that I think will suffer from the same problem on all three driven shafts - they just didn't see it as a potential problem when deciding on it.

Brad93

Member

- Messages

- 18,520

- Location

- Essex, United Kingdom

This should only have two bearings this shaft as far as I knowMisalignment too - due to crap design and trying to mount three bearings on a shaft in close proximity, one of our machines bust a 5" shaft in a similar fashion.

I've had to warn my boss(es) about a conveyor they've bought from Holland that I think will suffer from the same problem on all three driven shafts - they just didn't see it as a potential problem when deciding on it.

Olderisbetter

Member

- Messages

- 3,766

- Location

- Wolverhampton

I did an alteration of the gates at the shop to match the ones next door which are curved at the top, a bit of wall paper to get the basic shape then used some chipboard as a template then bent the rail till it fitted nicely, the rail tops finish the job and stop urchins climbing over.

Blake's 7

Member

- Messages

- 205

- Location

- Ireland

Really nice work there with the gates, @Olderisbetter.

Blake's 7

Member

- Messages

- 205

- Location

- Ireland

About a year ago I picked up this piece of 12" diameter stainless steel pipe from my local scrap yard as I knew I'd have a use for it when the time came and until recently it's been lying under my office desk.

About a week or so ago I used the paper from a credit card terminal to mark a 4" high line around the pipe's circumference and then used an angle grinder to cut the excess off.

After that was done I used some of my school days geometry to cut it into four equal parts and then used the four sections in a 4" high mould for concrete as shown below.

The green spay bottle contains a mixture of diesel and a small bit of engine oil to act as a release agent when the concrete has set. I give the timber a light spray and then use a brush to work it in.

After a few days I take the clamps, the timber blocks and the steel sections out of the frame and I'm left with the pieces below. I already have twelve of them made and I cast four more today. When

my blocklayer returns he will use them give nice consistent rounded corners to some of the blockwork in the chimney breast and afterwards it will be plastered in lime mortar.

The 4" thickness of the mould and the steel sections matches the thickness of a concrete block.

About a week or so ago I used the paper from a credit card terminal to mark a 4" high line around the pipe's circumference and then used an angle grinder to cut the excess off.

After that was done I used some of my school days geometry to cut it into four equal parts and then used the four sections in a 4" high mould for concrete as shown below.

The green spay bottle contains a mixture of diesel and a small bit of engine oil to act as a release agent when the concrete has set. I give the timber a light spray and then use a brush to work it in.

After a few days I take the clamps, the timber blocks and the steel sections out of the frame and I'm left with the pieces below. I already have twelve of them made and I cast four more today. When

my blocklayer returns he will use them give nice consistent rounded corners to some of the blockwork in the chimney breast and afterwards it will be plastered in lime mortar.

The 4" thickness of the mould and the steel sections matches the thickness of a concrete block.

DAPPH

as dyslexik as I'm daft

- Messages

- 7,181

- Location

- Near to Cross Hands Llanelli SouthWales GB

Can you explain or point me to a tube clip please?Flood.

Kram

Member

- Messages

- 7,132

- Location

- Sussex

Sorted new tools holders, new spout on oiler bent 90 degrees, much better for lathe. Put a hole in handle and hung on wall.

Tapered delrin headlight mount pin. Headlight spacers, and a short video on how I turn brass for nice swarf.

Last clocked my er40 collet chuck after the brazing. The flange and body both measure the same runout within 0.004mm on dial gauge. Good the heat did not distort or move the shrink fit on mounting flange. Turned the excess silver solder from the face and the finish it can take is amazing. Cleaned up threads. Tomorrow I'll set up compound and recut the taper as theres a large blob of silver in there.

Hood

I am obsessed.

- Messages

- 17,397

- Location

- Carnoustie, Scotland

Flood coolant, don't think I have a youtube of the Triumph using Nylon but this is the CNC when I first fitted the SZGH controller to it.Can you explain or point me to a tube clip please?

My Old Landy

Engineering Mayhem

- Messages

- 3,334

- Location

- North Lincs

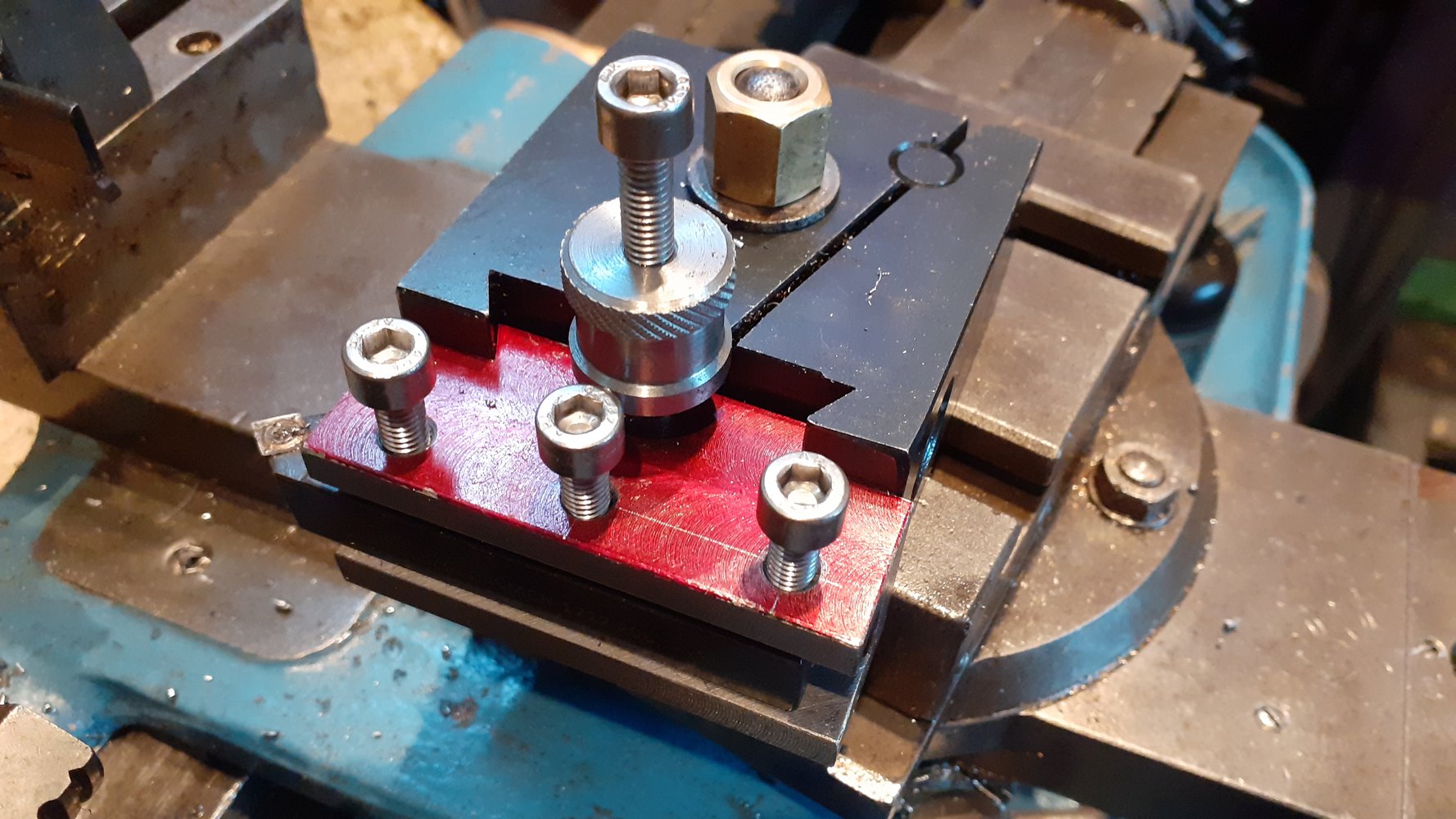

Finally finished the first of my qctp holders. Mild steel so may case harden once they are all done. Probably no point as I think they will out last me

The knurling is not brilliant but it works

The knurling is not brilliant but it works

That's the same design of toll post as mine - bought from Chester Machine tools a long time ago, with a couple of tool holders. I bought a couple more soon after - the dovetail is a different width meaning the "quick change" involves a fiar few more turns of the locking screw in or out, depending on which on. And all the tool clamp screws, while drilled parallel to each other, are not perpendicular to the actual holder.Finally finished the first of my qctp holders. Mild steel so may case harden once they are all done. Probably no point as I think they will out last me

The knurling is not brilliant but it works

View attachment 289979

Dovetail cutter arrived yesterday for me to make some more that fit properly . ..

DAPPH

as dyslexik as I'm daft

- Messages

- 7,181

- Location

- Near to Cross Hands Llanelli SouthWales GB

Ah ... That's cheating using a posh machine and cutting fluids .. I have the antique Sphere cira 1943 so don't have a wet set up ( not likely to either ) I usually cut everything dry or or use a spot of compressor oil on an artist paint brush or use WD40 through the tube attachment if I need lube. Might try and do that and see if I can get a better finish instead , it never occurred for me to use lubrication ..Flood coolant, don't think I have a youtube of the Triumph using Nylon but this is the CNC when I first fitted the SZGH controller to it.

Hood

I am obsessed.

- Messages

- 17,397

- Location

- Carnoustie, Scotland

You need to keep nylon cool and I would think that more important than actual lubrication but...Ah ... That's cheating using a posh machine and cutting fluids .. I have the antique Sphere cira 1943 so don't have a wet set up ( not likely to either ) I usually cut everything dry or or use a spot of compressor oil on an artist paint brush or use WD40 through the tube attachment if I need lube. Might try and do that and see if I can get a better finish instead , it never occurred for me to use lubrication ..

I use flood all the time on the Triumph as well and always when turning nylon.

Hood

I am obsessed.

- Messages

- 17,397

- Location

- Carnoustie, Scotland

I think it would likely turn quite nicelyThanks very much .In that case any idea if -23 oC deep frozen nylon can be turned ?

don't fancy your chances of keeping any kind of tolerance on it though

don't fancy your chances of keeping any kind of tolerance on it though  Unless of course you are going to keep it in the freezer after you have made the part

Unless of course you are going to keep it in the freezer after you have made the part

Wedg1e

They call me Mr. Bodge-angles

- Messages

- 7,735

- Location

- Teesside, England

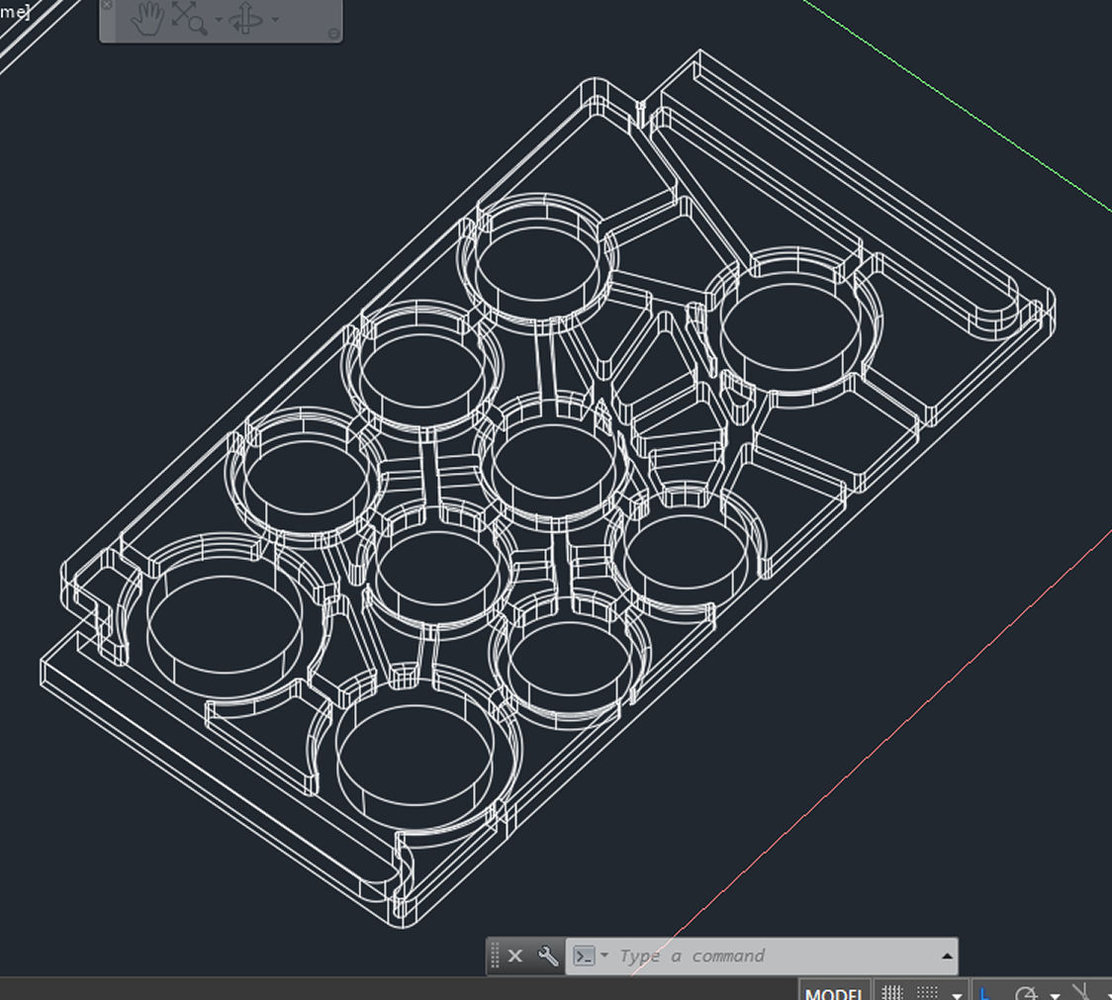

Not strictly 'today', nor is it finished yet, but as I'd gone to the trouble of making a collet adapter set for my Boxford VSL, it seemed like a good idea to acquire some collets. Then I needed somewhere to put them, and as the lathe's cabinet door already had 4 holes drilled in it, that looked like a good place to start.

Slotted uprights and shelf brackets (in brown to match the lathe! ) were found on Ebay and a shelf designed in CAD to suit them, then 3D printed.

) were found on Ebay and a shelf designed in CAD to suit them, then 3D printed.

This is the result, accommodating the drawtube and handwheel, plus collet closer and the spindle 3MT reducer as well as a few collets:

The second shelf (note lower pair of brackets) will have more slots for collets, plus tailstock drill chuck and maybe live centre. I was going to make the shelves from 3mm alloy plate but a poor stiffening fold on the first attempt caused a rethink. For the moment it takes the weight of the drawtube and provides a home for the chuck locking key:

The odd-looking alloy blocks at the ends of the shelf uprights are there because whoever drilled the door holes failed to get any two of them square to each other or any edge of the door, so the blocks are drilled off-centre to allow the uprights to be parallel!

Slotted uprights and shelf brackets (in brown to match the lathe!

) were found on Ebay and a shelf designed in CAD to suit them, then 3D printed.

) were found on Ebay and a shelf designed in CAD to suit them, then 3D printed.This is the result, accommodating the drawtube and handwheel, plus collet closer and the spindle 3MT reducer as well as a few collets:

The second shelf (note lower pair of brackets) will have more slots for collets, plus tailstock drill chuck and maybe live centre. I was going to make the shelves from 3mm alloy plate but a poor stiffening fold on the first attempt caused a rethink. For the moment it takes the weight of the drawtube and provides a home for the chuck locking key:

The odd-looking alloy blocks at the ends of the shelf uprights are there because whoever drilled the door holes failed to get any two of them square to each other or any edge of the door, so the blocks are drilled off-centre to allow the uprights to be parallel!