You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 19,776

- Location

- Going Away.

Had a lazy day, have to stay clean and keep a phone to hand. Ready to deal with customers.

So good coffee, good music and no power tools. The only electricity used was for lights and cd player. Water was boiled on a paraffin stove.

This J Tyzack Millwrights Dressing toll arrived in this condition. Complete, dirty. but with the dirt of age. The tips had been badly dressed over time.

The wedge was swollen with old wax and oil.

The manufactures name was revealed in the cleaning and dressing of the edges.

The cleaning showed a name stamped into 2 places on the wooden handle, the wedge and the blade.

R. L. Hickman.

The metal was cleaned with wire wool, White snake. Then warmed on the stove and wax polished in.

The wood was cleaned up with "Meths" and wire wool. This showed up the grain of the beech. The wood was finished with a custom shaped cabinet scraper.

The wedge, is Oak. It needed to be reduced in width. But removing the excess would show up as new wood.

So, clean with "Meths" and wire wool. But keep the dirty "Meths".

Dress back the wood with files, on both sides. Then key with course sand paper.

By this time the dirty "Meths" should of reduced and left you with a dirty sludge. Add some soft wax to make a paste. Then using a fine wire wool stain the exposed new wood.

Sanding sealer and Polish.

The polish is home made, dissolve shellac with cheep nail varnish remover and apply with a soft cloth.

This is the old wet stone used to dress the cutting edges.

As it was 4am, the music was classic 80's rock and illuminated by a storm lamp.

The handle is stuck on with rock sulphur and was not going to come of with out a fight and noise.

The tip had been droped at some point and was burred over. One rivet was loose.

Cleaning up showed a manufactures name.

Monument Brand.

Plus the Number 28 on the other side.

The tip was dressed to give 1 square edge and the other 3 are radius to different amounts.

Cleaned, polished and waxed.

The rivet was made sound by heating and pressing it in a vice.

The handle has been repaired at some point in it's life, you can see the welds on the bar to head.

So good coffee, good music and no power tools. The only electricity used was for lights and cd player. Water was boiled on a paraffin stove.

This J Tyzack Millwrights Dressing toll arrived in this condition. Complete, dirty. but with the dirt of age. The tips had been badly dressed over time.

The wedge was swollen with old wax and oil.

The manufactures name was revealed in the cleaning and dressing of the edges.

The cleaning showed a name stamped into 2 places on the wooden handle, the wedge and the blade.

R. L. Hickman.

The metal was cleaned with wire wool, White snake. Then warmed on the stove and wax polished in.

The wood was cleaned up with "Meths" and wire wool. This showed up the grain of the beech. The wood was finished with a custom shaped cabinet scraper.

The wedge, is Oak. It needed to be reduced in width. But removing the excess would show up as new wood.

So, clean with "Meths" and wire wool. But keep the dirty "Meths".

Dress back the wood with files, on both sides. Then key with course sand paper.

By this time the dirty "Meths" should of reduced and left you with a dirty sludge. Add some soft wax to make a paste. Then using a fine wire wool stain the exposed new wood.

Sanding sealer and Polish.

The polish is home made, dissolve shellac with cheep nail varnish remover and apply with a soft cloth.

This is the old wet stone used to dress the cutting edges.

As it was 4am, the music was classic 80's rock and illuminated by a storm lamp.

The other item I managed to get some time on was this 2lb Copper soldering iron.

The handle is stuck on with rock sulphur and was not going to come of with out a fight and noise.

The tip had been droped at some point and was burred over. One rivet was loose.

Cleaning up showed a manufactures name.

Monument Brand.

Plus the Number 28 on the other side.

The tip was dressed to give 1 square edge and the other 3 are radius to different amounts.

Cleaned, polished and waxed.

The rivet was made sound by heating and pressing it in a vice.

The handle has been repaired at some point in it's life, you can see the welds on the bar to head.

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 19,776

- Location

- Going Away.

Wedg1e

They call me Mr. Bodge-angles

- Messages

- 7,735

- Location

- Teesside, England

Some years back we fitted out a purpose-built ISO container-style cabin as an x-ray facility. The exposure room is roughly an 8 foot cube and all sides plus the doors (it has an emergency exit) were lined with a minimum 10mm of lead. We had the lead cast as 1000 x 500mm slabs by Calder in Chester, but of course all the joins had to be covered with matching narrow strips as otherwise the x-rays would pass through the gaps. So some of the slabs were put through a saw table (you really need a leather apron to deflect the chippings, they sting a bit!). When the floor had been swept and the chippings melted down, we had a couple of beers on the proceedsstarting weight 4kg. Lost 315g to the saw and slag

- about 120Kg as I recall (the lead, not the beer

- about 120Kg as I recall (the lead, not the beer  )

)We've just recommissioned an irradiation system at a university, originally built by us (OK, me

) in 2008 and now upgraded with new control electrics, a stainless steel cabinet and even more lead shielding - 1200Kg of the stuff, most of it forming a 500mm cube with 50mm wall. Has to be that thick so that research students can stand next to it while they nuke the contents with 320kV of x-rays.

) in 2008 and now upgraded with new control electrics, a stainless steel cabinet and even more lead shielding - 1200Kg of the stuff, most of it forming a 500mm cube with 50mm wall. Has to be that thick so that research students can stand next to it while they nuke the contents with 320kV of x-rays.Gareth0123

You'll need 16 pigs to do the job in one sitting!

- Messages

- 1,559

- Location

- Norwich, Norfolk, UK

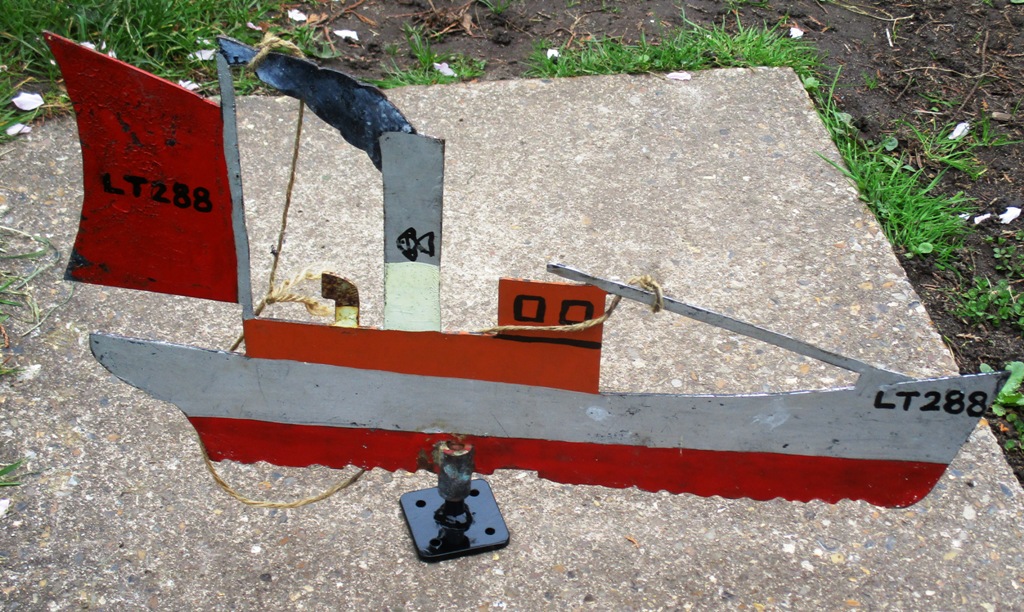

LT288 Renascent.

I was asked by a previously regular customer to do a little job for him. I explained to him that my business is currently mothballed due to my illness and that I am only selling previously made items still in stock, but I was now doing a little light duty project work for myself, family and friends just to keep my hand in and as a sort of maintenance thingy to ensure my rather expensive equipment wasn't rusting away or any damp getting on to circuit boards in the welders, drills, saws, grinders compressors and plasma cutters, etc.

Anyway, as a favour I agreed to make him a rather simple but serviceable pivot plinth for a weathervane belonging to one of his neighbours.

Nothing spectacular or complicated and suitable to mount this weathervane on the end of a garden shed roof.

The black painted plate with a pivot rod is what I made; simple and practical, nothing more and nothing less. 5 x 50 x 50 MS flat. 4 of 4mmØ holes, 1 x10mmØ hole, 50mm x 10mmØ MS bar, a zap with my R-Tech mig welder and a lick of paint.

Obviously because I am ill and not presently working I refused to take any kind of payment, but the gentleman I did this job for made a £20.00 donation to Sea Palling Independent Lifeboat as a way of thanking me.

After he had collected the weathervane this afternoon it was only then out of curiosity I decided to Google LT288 and to try and find some photos of her or maybe even find her present position on one of the ship tracking websites.

I knew from the LT designation she was a Lowestoft registered vessel and this is what I found on google: www.wildfire3.com/renascent.html

I was asked by a previously regular customer to do a little job for him. I explained to him that my business is currently mothballed due to my illness and that I am only selling previously made items still in stock, but I was now doing a little light duty project work for myself, family and friends just to keep my hand in and as a sort of maintenance thingy to ensure my rather expensive equipment wasn't rusting away or any damp getting on to circuit boards in the welders, drills, saws, grinders compressors and plasma cutters, etc.

Anyway, as a favour I agreed to make him a rather simple but serviceable pivot plinth for a weathervane belonging to one of his neighbours.

Nothing spectacular or complicated and suitable to mount this weathervane on the end of a garden shed roof.

The black painted plate with a pivot rod is what I made; simple and practical, nothing more and nothing less. 5 x 50 x 50 MS flat. 4 of 4mmØ holes, 1 x10mmØ hole, 50mm x 10mmØ MS bar, a zap with my R-Tech mig welder and a lick of paint.

Obviously because I am ill and not presently working I refused to take any kind of payment, but the gentleman I did this job for made a £20.00 donation to Sea Palling Independent Lifeboat as a way of thanking me.

After he had collected the weathervane this afternoon it was only then out of curiosity I decided to Google LT288 and to try and find some photos of her or maybe even find her present position on one of the ship tracking websites.

I knew from the LT designation she was a Lowestoft registered vessel and this is what I found on google: www.wildfire3.com/renascent.html

Last edited:

Hood

I am obsessed.

- Messages

- 17,380

- Location

- Carnoustie, Scotland

Bored and tapped a hole in the C4 holder so that coolant can be directed to the boring bar, works well and the Loc-Line coolant pipe just pushes in so is easily removed when I remove the tool.

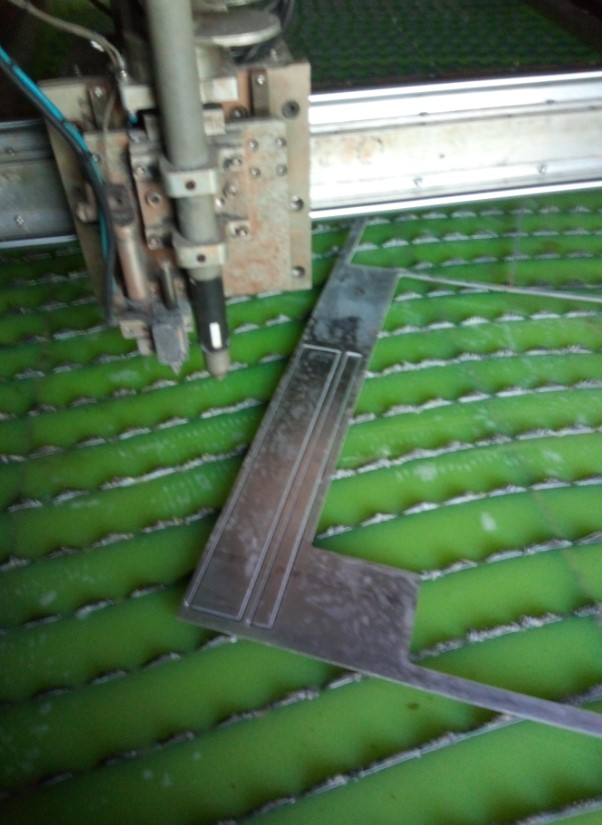

Also wrote a macro for rotating the toolpath on the plasma, never really had a need for it but might come in handy one day. One issue I have found though is the CSMIO controller I use does not work in Jog as Mach with the parallel port would. It still jogs along the conventional X and Y where with the parallel port it would run along the rotated X or Y when jogging, so that is not so good

Still it can still be used fine from G Code as can be seen from the two bits I cut in a plate that was angled about 45 degrees to normal.

Also wrote a macro for rotating the toolpath on the plasma, never really had a need for it but might come in handy one day. One issue I have found though is the CSMIO controller I use does not work in Jog as Mach with the parallel port would. It still jogs along the conventional X and Y where with the parallel port it would run along the rotated X or Y when jogging, so that is not so good

Still it can still be used fine from G Code as can be seen from the two bits I cut in a plate that was angled about 45 degrees to normal.

You got a link for loc line coolant pipe?Bored and tapped a hole in the C4 holder so that coolant can be directed to the boring bar, works well and the Loc-Line coolant pipe just pushes in so is easily removed when I remove the tool.

View attachment 290429

Also wrote a macro for rotating the toolpath on the plasma, never really had a need for it but might come in handy one day. One issue I have found though is the CSMIO controller I use does not work in Jog as Mach with the parallel port would. It still jogs along the conventional X and Y where with the parallel port it would run along the rotated X or Y when jogging, so that is not so good

Still it can still be used fine from G Code as can be seen from the two bits I cut in a plate that was angled about 45 degrees to normal.

View attachment 290430

Hood

I am obsessed.

- Messages

- 17,380

- Location

- Carnoustie, Scotland

Ok Chronos stuff is not genuine.

www.chronos.ltd.uk

www.chronos.ltd.uk

Zoro however is

www.zoro.co.uk

www.zoro.co.uk

MSC is also genuine

www.mscdirect.co.uk

www.mscdirect.co.uk

Adjustable Coolant Hose Set - Chronos Engineering Supplies

Adjustable Coolant Hose Set from Chronos Engineering Supplies. Free UK delivery and great worldwide rates.

www.chronos.ltd.uk

www.chronos.ltd.uk

Zoro however is

Modular Coolant Hose Systems and Kits | Zoro UK

Modular Coolant Hose Systems and Kits, 7 products available to order online. Next day delivery available on most items, free delivery on orders over £25!

MSC is also genuine

Loc-Line COOLANT DELIVERY SYSTEMS - 1/8-1/4 LOC-LINE HOSE ASSEMBLY 13" SET

It was more the pipe I was trying to find mate.You can get it more or less any place, I prefer to get the genuine stuff rather than the knockoff.

MSC Direct, Zoro, Chronos etc likely have it.

Hood

I am obsessed.

- Messages

- 17,380

- Location

- Carnoustie, Scotland

What pipe?It was more the pipe I was trying to find mate.

That takes the coolant from the pumpWhat pipe?

doubleboost

Member

- Messages

- 3,821

- Location

- Newcastle upon Tyne England

DAPPH

as dyslexik as I'm daft

- Messages

- 7,169

- Location

- Near to Cross Hands Llanelli SouthWales GB

Had a lazy day, have to stay clean and keep a phone to hand. Ready to deal with customers.

So good coffee, good music and no power tools. The only electricity used was for lights and cd player. Water was boiled on a paraffin stove.

This J Tyzack Millwrights Dressing toll arrived in this condition. Complete, dirty. but with the dirt of age. The tips had been badly dressed over time.

The wedge was swollen with old wax and oil.

View attachment 290350

The manufactures name was revealed in the cleaning and dressing of the edges.

View attachment 290353

The cleaning showed a name stamped into 2 places on the wooden handle, the wedge and the blade.

R. L. Hickman.

The metal was cleaned with wire wool, White snake. Then warmed on the stove and wax polished in.

The wood was cleaned up with "Meths" and wire wool. This showed up the grain of the beech. The wood was finished with a custom shaped cabinet scraper.

View attachment 290354

The wedge, is Oak. It needed to be reduced in width. But removing the excess would show up as new wood.

So, clean with "Meths" and wire wool. But keep the dirty "Meths".

Dress back the wood with files, on both sides. Then key with course sand paper.

By this time the dirty "Meths" should of reduced and left you with a dirty sludge. Add some soft wax to make a paste. Then using a fine wire wool stain the exposed new wood.

View attachment 290355

Sanding sealer and Polish.

The polish is home made, dissolve shellac with cheep nail varnish remover and apply with a soft cloth.

View attachment 290356

This is the old wet stone used to dress the cutting edges.

As it was 4am, the music was classic 80's rock and illuminated by a storm lamp.

View attachment 290358

The other item I managed to get some time on was this 2lb Copper soldering iron.

View attachment 290359

The handle is stuck on with rock sulphur and was not going to come of with out a fight and noise.

The tip had been droped at some point and was burred over. One rivet was loose.

View attachment 290361

Cleaning up showed a manufactures name.

Monument Brand.

Plus the Number 28 on the other side.

The tip was dressed to give 1 square edge and the other 3 are radius to different amounts.

View attachment 290362

Cleaned, polished and waxed.

The rivet was made sound by heating and pressing it in a vice.

The handle has been repaired at some point in it's life, you can see the welds on the bar to head.

From my apprenticeship tin bashing days over 50 yrs ago ..... IIRC 28 on the stamp usually means a 28 ounce head of copper , On that particular Tinmans 28 oz iron all edges on the pointy bit should be clean sharp edges & flat faces so you can easily sweat solder along seams or tin plate patches turning the iron as needed . Do you ever get any of the old Tinman's axe head irons for seam soldering ?

Kram

Member

- Messages

- 7,091

- Location

- Sussex

After recutting the Er40 yesterday and compound being set up, I started on the Chinese ER32, taper was undersized so perfect for recutting. A lot of swearing at my compound handle which is a pain to use and took blood.

Im not sure what is wrong but the result is terrible. The Er32 shaft measures 1 div runout (0.002mm), so the ER40 result is good. The newely cut ER32 taper measures 0.002mm, yet when I mount a shaft in it (using new HSS blanks, as they'll be ground) it is 0.2mm out! I tried several peices of HSS, different sizes/collets/nuts

Another go tomorrow.

Another go tomorrow.The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 19,776

- Location

- Going Away.

The on line catalog showed two types of monument brand 28oz heads.From my apprenticeship tin bashing days over 50 yrs ago ..... IIRC 28 on the stamp usually means a 28 ounce head of copper , On that particular Tinmans 28 oz iron all edges on the pointy bit should be clean sharp edges & flat faces so you can easily sweat solder along seams or tin plate patches turning the iron as needed . Do you ever get any of the old Tinman's axe head irons for seam soldering ?

One with nice crisp square corners to joint work.

The other with different radius corners for doing soldered joints on curves.

I have many a squared edge bit come through and a few radius heads.

My farther in law, a time served sheet metal worker has about 50 copper soldering irons, 2 paraffin heating furnaces and 2 copper dish blocks.

I am still looking through the catalog of tools the sales men gave out in the 1960's.

One even had his own headed order pages in.

I have recently done a small tinsman Axe head.

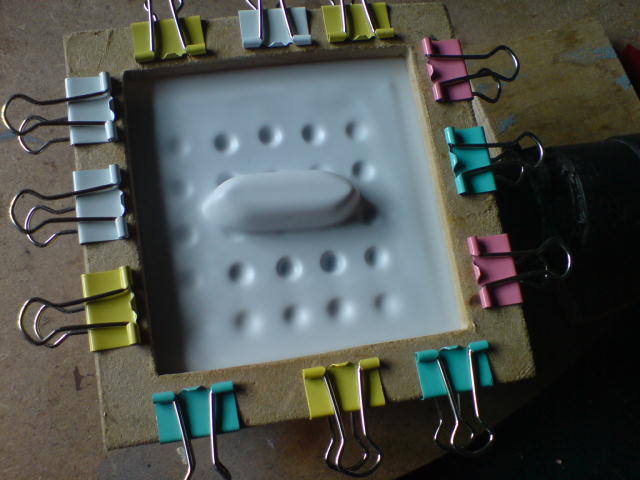

today I have been vac forming some styrene sheet to make a hull for a lifeboat of a model boat I'm making, but I thought I'd try and vac form it rather than making it from solid to save weight......and the lifeboat is only 40mm long

and I used 1,00mm thick styrene.

and I used 1,00mm thick styrene.

after watching a couple of videos in youtube it seems to be a very simple process and it was.

the first thing to do was make vaccum box to put the item on that you want to copy and it needs to be able to connect to a vacuum cleaner. the bottom of mine was made from offcuts of mdf and plywood. the top was made from steel and stuck in place with car body filler

I painted the top black to stop it rusting for future use and on it is the aluminium former for the lifeboat that I want to copy. the former is a couple of mm taller than the finished item.

all ready to go now, a frame was cut from mdf and the styrene sheet was held to it with paper/bulldog clips. I held the frame at the corner. the vacuum cleaner was switched on and the styrene was heated up with a hot air paint stripper at a temperature that I would normally use for shrinking heatshrink so not too hot and when the styene starts to sag its hot enough do the vac forming.

and quickly lower it over the vacuum box and there to have it.

on the left is the aluminium former, on the middle is a lifeboat after vac forming, and on the right is the finished hull.

I was orginally going to heat the styrene in an oven, but with a variable temperature heat gun and seeing the sheet sagging its easy enough to do. think it should work for other thermoplastics too.

and I used 1,00mm thick styrene.

and I used 1,00mm thick styrene.after watching a couple of videos in youtube it seems to be a very simple process and it was.

the first thing to do was make vaccum box to put the item on that you want to copy and it needs to be able to connect to a vacuum cleaner. the bottom of mine was made from offcuts of mdf and plywood. the top was made from steel and stuck in place with car body filler

I painted the top black to stop it rusting for future use and on it is the aluminium former for the lifeboat that I want to copy. the former is a couple of mm taller than the finished item.

all ready to go now, a frame was cut from mdf and the styrene sheet was held to it with paper/bulldog clips. I held the frame at the corner. the vacuum cleaner was switched on and the styrene was heated up with a hot air paint stripper at a temperature that I would normally use for shrinking heatshrink so not too hot and when the styene starts to sag its hot enough do the vac forming.

and quickly lower it over the vacuum box and there to have it.

on the left is the aluminium former, on the middle is a lifeboat after vac forming, and on the right is the finished hull.

I was orginally going to heat the styrene in an oven, but with a variable temperature heat gun and seeing the sheet sagging its easy enough to do. think it should work for other thermoplastics too.