You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

My Old Landy

Engineering Mayhem

- Messages

- 3,333

- Location

- North Lincs

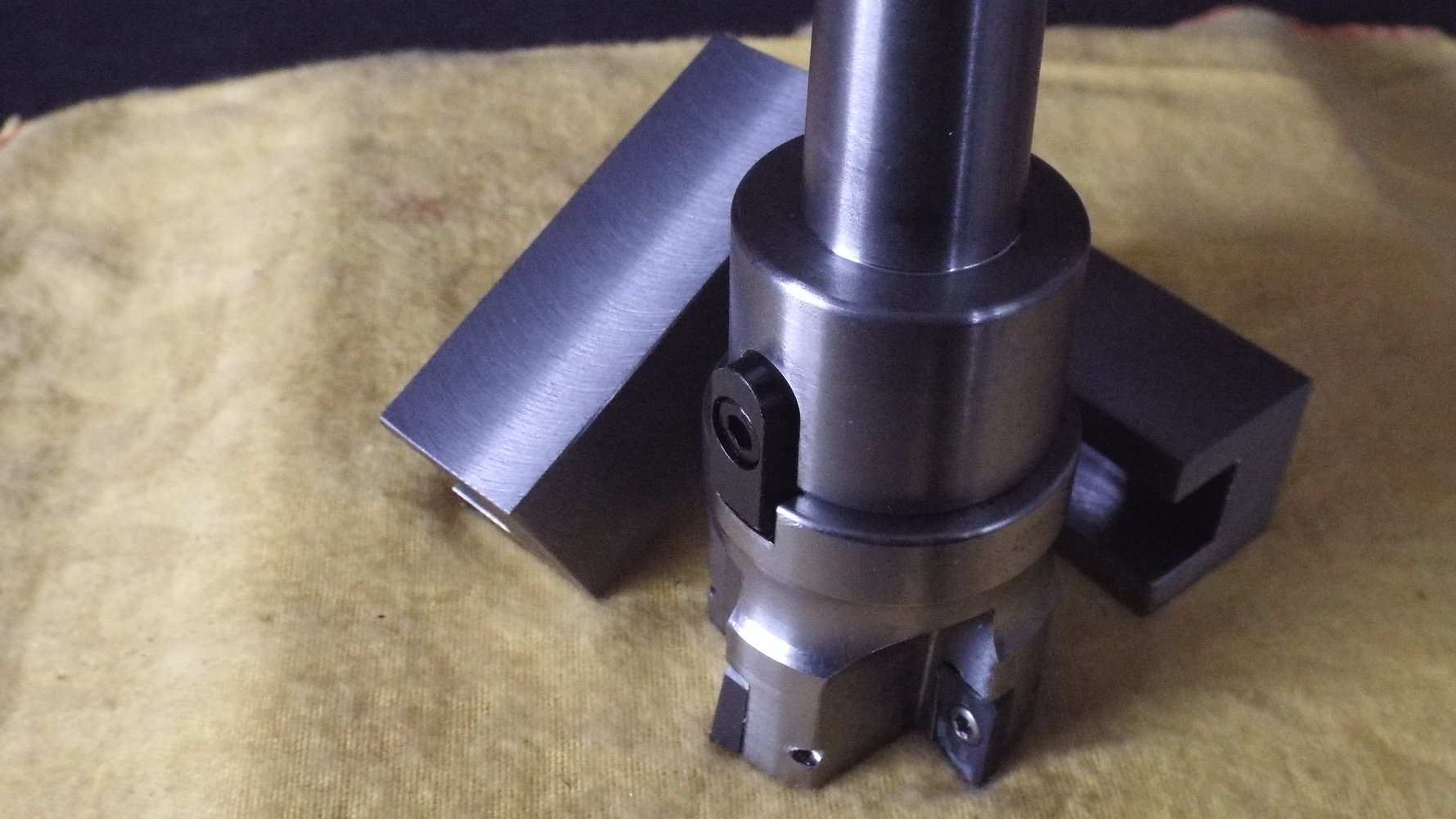

I had a play with a new 50mm face cutter. Made some chips and some black bar square

As is tradition, a short video to send you to sleep!

As is tradition, a short video to send you to sleep!

Made serious inroads on my home-made table saw this weekend. After pricing up a new one I came across lots of "how to make a table saw from a circular saw" videos on YouTube and as I had a circular saw sat doing nothing and plenty of 3/4" board, I gave it a go:

Still have to finish the rip fence, make a mitre fence, rout 2 mitre slots in the table, fit an on/off switch and a port for dust extraction, possibly cut 2 holes in the front for storage, then give it all a good sanding and put some wax on the table, but I'm very pleased with it so far.

Spent some time squaring the blade to the front of the table before bolting the saw tight then ripped an old piece of board through it using a clamped on temporary fence squared up by eye, and over 24" the width was 4 thou' out so I'm happy enough with that .

.

Still have to finish the rip fence, make a mitre fence, rout 2 mitre slots in the table, fit an on/off switch and a port for dust extraction, possibly cut 2 holes in the front for storage, then give it all a good sanding and put some wax on the table, but I'm very pleased with it so far.

Spent some time squaring the blade to the front of the table before bolting the saw tight then ripped an old piece of board through it using a clamped on temporary fence squared up by eye, and over 24" the width was 4 thou' out so I'm happy enough with that

.

.Dr.Al

Forum Supporter

- Messages

- 2,357

- Location

- Gloucestershire, UK

Made serious inroads on my home-made table saw this weekend. After pricing up a new one I came across lots of "how to make a table saw from a circular saw" videos on YouTube and as I had a circular saw sat doing nothing and plenty of 3/4" board, I gave it a go:

View attachment 290577

View attachment 290580

Still have to finish the rip fence, make a mitre fence, rout 2 mitre slots in the table, fit an on/off switch and a port for dust extraction, possibly cut 2 holes in the front for storage, then give it all a good sanding and put some wax on the table, but I'm very pleased with it so far.

Spent some time squaring the blade to the front of the table before bolting the saw tight then ripped an old piece of board through it using a clamped on temporary fence squared up by eye, and over 24" the width was 4 thou' out so I'm happy enough with that.

Looks nice! Are you going to add some sort of riving knife/splitter?

James1979

Member

- Messages

- 8,434

- Location

- Orkney

Been after one of those hammer moulds for years. Did you buy that new John?Mould to cast 5 mill lead to go through a bullet die

View attachment 290441 View attachment 290442 View attachment 290443 View attachment 290444

Red'n'Black

Forum Supporter

- Messages

- 687

- Location

- Malvern, Worcs

Some hooks, made from 10mm 316 stainless.

Wasn't getting very far with a propane torch so bought some MAPP gas. Much better!

Even heated up cherry red it needed some serious leaning on.

Cleaned up OK.

Test fit. Think they'll do the job. Sod's law, that instantly brought on the rain...

I've given up buying products online that claim to be stainless, they seem to go rusty as soon as it gets a bit damp.

Wasn't getting very far with a propane torch so bought some MAPP gas. Much better!

Even heated up cherry red it needed some serious leaning on.

Cleaned up OK.

Test fit. Think they'll do the job. Sod's law, that instantly brought on the rain...

I've given up buying products online that claim to be stainless, they seem to go rusty as soon as it gets a bit damp.

My Old Landy

Engineering Mayhem

- Messages

- 3,333

- Location

- North Lincs

They look really substantial and better than any I have seen for that applicationSome hooks, made from 10mm 316 stainless.

Wasn't getting very far with a propane torch so bought some MAPP gas. Much better!

View attachment 290608

Even heated up cherry red it needed some serious leaning on.

View attachment 290610

Cleaned up OK.

View attachment 290611

Test fit. Think they'll do the job. Sod's law, that instantly brought on the rain...

View attachment 290613

I've given up buying products online that claim to be stainless, they seem to go rusty as soon as it gets a bit damp.

Red'n'Black

Forum Supporter

- Messages

- 687

- Location

- Malvern, Worcs

Yes a running joke in our house is that I tend to over-engineer things. But build one thing that collapses with weight on it and I'd never hear the end of itThey look really substantial and better than any I have seen for that application

MattF

Forum Supporter

- Messages

- 16,814

- Location

- South Yorkshire

But build one thing that collapses with weight on it and I'd never hear the end of it

It's be hoped you've never phrased it like that to your other half, if you value your nads.

doubleboost

Member

- Messages

- 3,821

- Location

- Newcastle upon Tyne England

Yes Bought it in AmericaBeen after one of those hammer moulds for years. Did you buy that new John?

gaz1

Member

- Messages

- 19,270

- Location

- westyorkshire

your going to have some fun with that model and yes ive seen it just didnt want that typeMade serious inroads on my home-made table saw this weekend. After pricing up a new one I came across lots of "how to make a table saw from a circular saw" videos on YouTube and as I had a circular saw sat doing nothing and plenty of 3/4" board, I gave it a go:

View attachment 290577

View attachment 290580

Still have to finish the rip fence, make a mitre fence, rout 2 mitre slots in the table, fit an on/off switch and a port for dust extraction, possibly cut 2 holes in the front for storage, then give it all a good sanding and put some wax on the table, but I'm very pleased with it so far.

Spent some time squaring the blade to the front of the table before bolting the saw tight then ripped an old piece of board through it using a clamped on temporary fence squared up by eye, and over 24" the width was 4 thou' out so I'm happy enough with that.

this one i prefer

easier and lighter and has way more functions with it

and to note its the size of a proper table saw of the dewalt type

DeWalt DWE7485 210mm Compact Table Saw 1850W 240V & DE7400 Saw Stand

We are the UK's fastest growing Power Tool distributor. Supplying Power Tools, Hand Tools, Tool Accessories and Safety Equipment across the UK & Europe.

www.toolden.co.uk

www.toolden.co.uk

James1979

Member

- Messages

- 8,434

- Location

- Orkney

May be the only way. Tax and shipping’s the killer.Yes Bought it in America

zx9

Forum Supporter

- Messages

- 5,179

- Location

- South East London

I think aYes a running joke in our house is that I tend to over-engineer things. But build one thing that collapses with weight on it and I'd never hear the end of it

James1979

Member

- Messages

- 8,434

- Location

- Orkney

Guilty!I think afew ofmost us here are probably in the same boat.

although I build stuff that people seem to take delight in testing to the max and some. Well that’s my excuse anyway!

mtt.tr

Member

- Messages

- 8,432

- Location

- Essex/Suffolk border

Any good for ali and copper?May be the only way. Tax and shipping’s the killer.

I saved the riving knife from the circular saw and it won't be too much work to fit it back on if I extend the slot for the blade.Looks nice! Are you going to add some sort of riving knife/splitter?

I initially plunge cut the slot with the blade then opened it out with my new Dewalt handheld router so I could square the blade to the front of the table. This has left me with a 1/4" wide slot for the blade but I don't see thin cuts being a feature of my very modest efforts as yet, but if they do I might see about making a zero clearance insert.

JMS1972

Member

- Messages

- 1,208

- Location

- NW Leicestershire, UK

Is the nut or thread distorting the collets?View attachment 290456

After recutting the Er40 yesterday and compound being set up, I started on the Chinese ER32, taper was undersized so perfect for recutting. A lot of swearing at my compound handle which is a pain to use and took blood.

Im not sure what is wrong but the result is terrible. The Er32 shaft measures 1 div runout (0.002mm), so the ER40 result is good. The newely cut ER32 taper measures 0.002mm, yet when I mount a shaft in it (using new HSS blanks, as they'll be ground) it is 0.2mm out! I tried several peices of HSS, different sizes/collets/nutsAnother go tomorrow.

doubleboost

Member

- Messages

- 3,821

- Location

- Newcastle upon Tyne England

It is cast iron so should be good for alloy the copper would need a cutting torch to melt itAny good for ali and copper?

James1979

Member

- Messages

- 8,434

- Location

- Orkney

Hadn’t thought about it but that’s a good idea.Any good for ali and copper?

the ones I’ve seen come with a handle as a kit. Reasonable price but it’s tax and shipping