jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

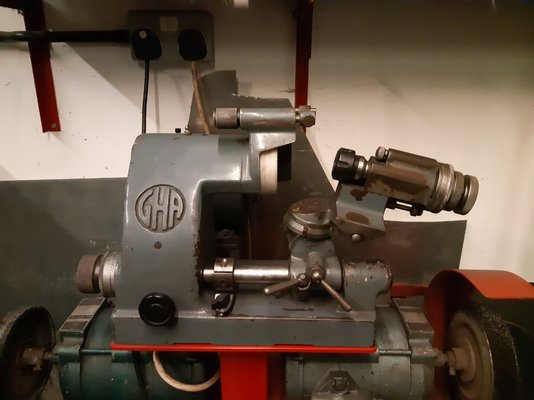

Thought I would make a first post on the Tool and cutter grinder build. As I cannot afford a Clarkson tool and cutter grinder I have been eyeing up this type

but wow they make lots of money for what is basically a grinder, with more accuracy.

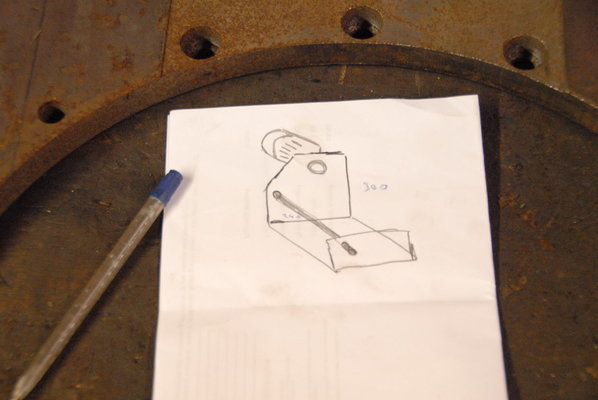

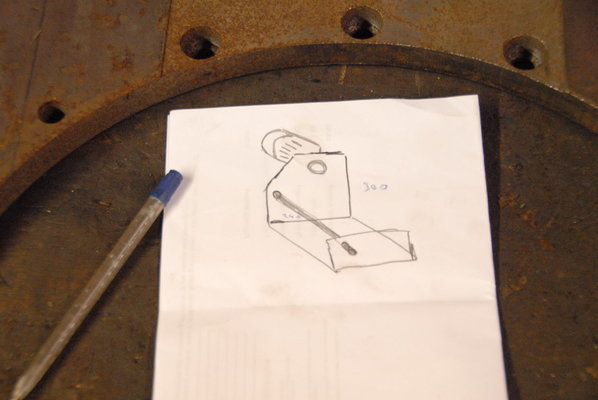

This is the base idea I am hoping to put together,

once I have this part sorted I will then sort out the swively parts, as per normal there is no planning apart from a bit of a sketch while having a cuppa.

Father had to got near the scrap recycling yard today so I went with him and manage to grab some steal plate the straightest I could find was some 20mm thick plate,

will need a bit of chopping about to get the size and shape I have in mind. I also picked up some round bar but it only 22mm and I have got the boring bar stuff

although its a bit thick and to wasteful to turn it down to about 25mm.

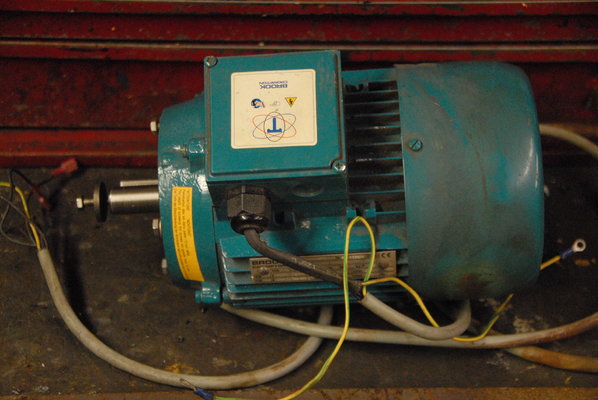

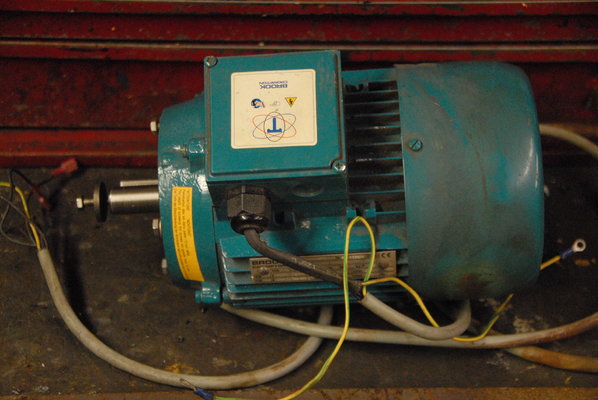

I did find an old motor that is face fitting but it is only 1605rpm,

will this be a bit slow or do you think it will do, The ones I have seen on the net are 3000rpm and up. I am hoping to fix the grind wheel directly to the shaft so will be direct drive as I don't think I will have space for pulleys and belts

Jord

but wow they make lots of money for what is basically a grinder, with more accuracy.

This is the base idea I am hoping to put together,

once I have this part sorted I will then sort out the swively parts, as per normal there is no planning apart from a bit of a sketch while having a cuppa.

Father had to got near the scrap recycling yard today so I went with him and manage to grab some steal plate the straightest I could find was some 20mm thick plate,

will need a bit of chopping about to get the size and shape I have in mind. I also picked up some round bar but it only 22mm and I have got the boring bar stuff

although its a bit thick and to wasteful to turn it down to about 25mm.

I did find an old motor that is face fitting but it is only 1605rpm,

will this be a bit slow or do you think it will do, The ones I have seen on the net are 3000rpm and up. I am hoping to fix the grind wheel directly to the shaft so will be direct drive as I don't think I will have space for pulleys and belts

Jord

, a Quorn packed in three boxes in the cave - I'm resisting even unpacking them because I just know I'd launch into refur'b/rebuilding it. The only thing I've done is check the motor which came does it's whirly thing, and it does

, a Quorn packed in three boxes in the cave - I'm resisting even unpacking them because I just know I'd launch into refur'b/rebuilding it. The only thing I've done is check the motor which came does it's whirly thing, and it does  It's had to take its place on the list until it can receive my undivided attention, preferably when the weather's a bit better.

It's had to take its place on the list until it can receive my undivided attention, preferably when the weather's a bit better.

I have changed my mind on the Deckel type and decided on a Quorn type cutter grinder as for what research I have done it will give me more options. Its not a lot but I have managed to chomp out some more forklift tine

I have changed my mind on the Deckel type and decided on a Quorn type cutter grinder as for what research I have done it will give me more options. Its not a lot but I have managed to chomp out some more forklift tine