- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Home Made Tools and Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool and Cutter Grinder Build

- Thread starter jordhandson

- Start date

slim_boy_fat

Forum Supporter

- Messages

- 29,540

- Location

- Scottish Highlands

i caught this

Aye, that's the one that was on the'Bay for £990...... didn't sell....

jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

Hi all, hope you all had a good holiday period, I did, now its back to normal lol.

I did manage to get some time in the workshop and done a bit more of the grinder in between family things.

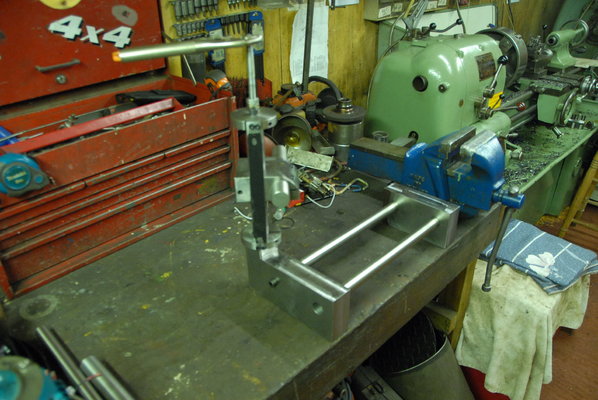

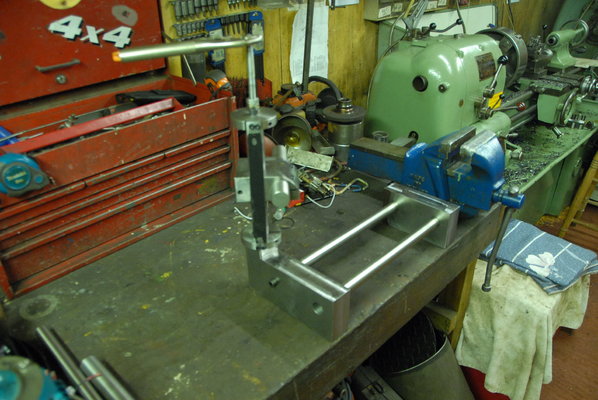

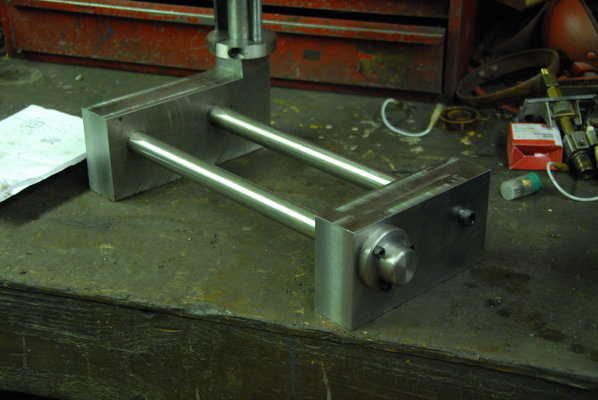

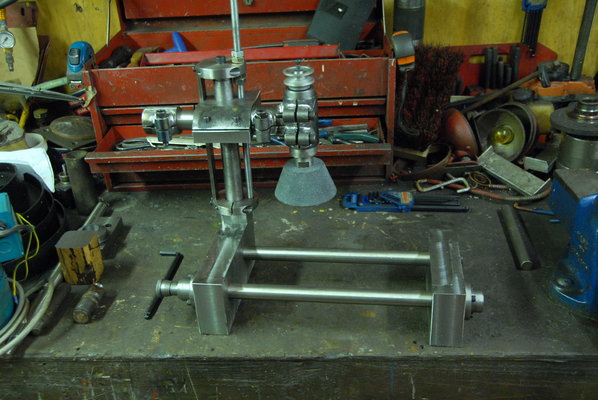

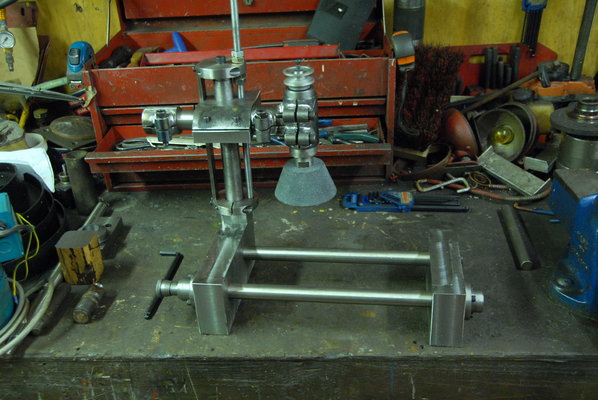

The swivelling motor and spindle mount is done, I just need to add a height scale on the upright bar later.

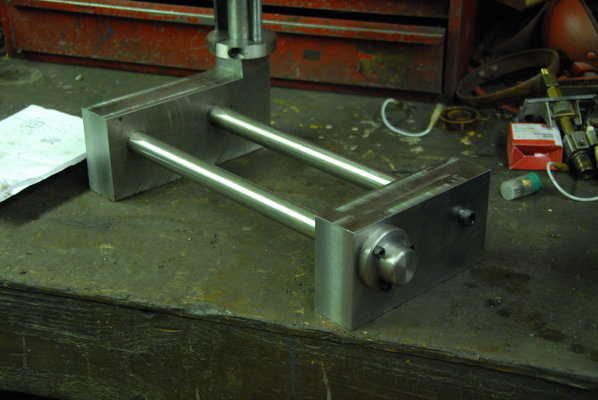

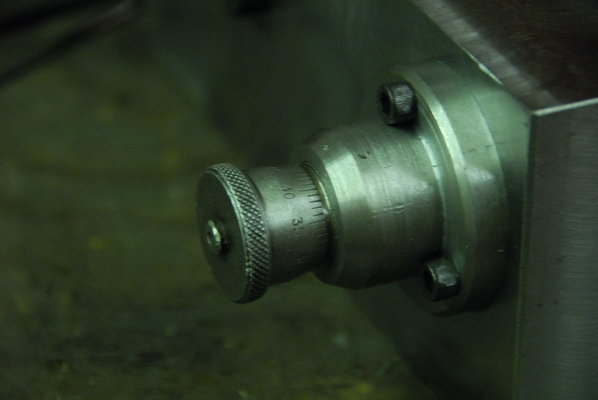

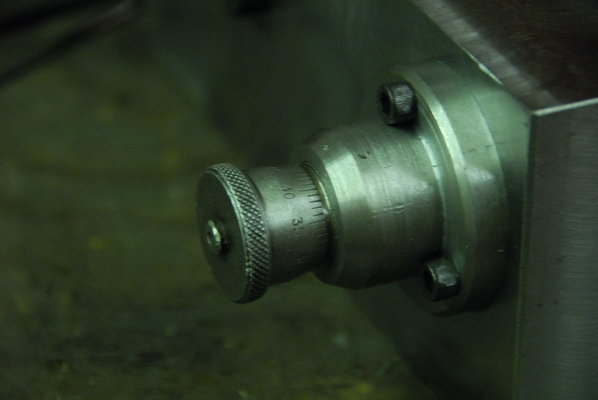

Still making do with things about the workshop, I had a broken lathe bed stop in the shelving with a micro adjustment screw in the end,

I decided to turn it down and would do for the front sliding bar, fitted a strong spring at the end, I have 15mm of travel, I reckon more than enough, I turned an end cap for the spring

and an adaptor for the micro screw

I was going to weld it but in the end it got fitted with grub screws, it works very well.

I have now turned to sorting out the pulley spindle part. I found in the shed an old Mansley cultivator tine shaft real good thick tubing 8-9mm and a couple of good acme threads from some old caravan legs that may come in handy later.

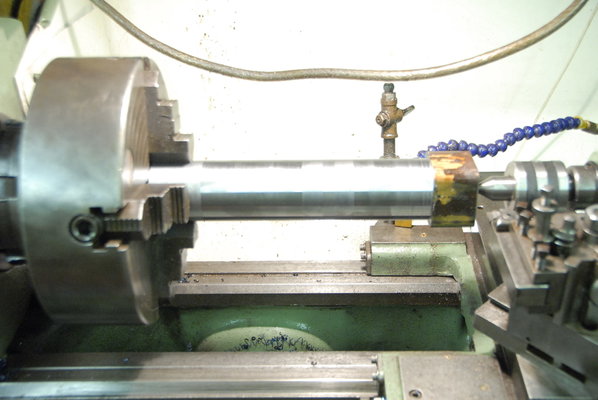

I turned the tubing down .

Today I turned the ends out for a couple of 40mm OD bearing I had, the id of the bearings is approx 17mm so I figure the shaft should be thick enough. I forgot to take a pic

It maybe a while before I get the shaft done, busy time now after the new year, down here the old boys start thinking of the tractor showing season. The phones be busy today already, I may have an interesting project coming in to restore, a 3 wheeled Allis Chalmers which should be interesting.

Cheers Jord

I did manage to get some time in the workshop and done a bit more of the grinder in between family things.

The swivelling motor and spindle mount is done, I just need to add a height scale on the upright bar later.

Still making do with things about the workshop, I had a broken lathe bed stop in the shelving with a micro adjustment screw in the end,

I decided to turn it down and would do for the front sliding bar, fitted a strong spring at the end, I have 15mm of travel, I reckon more than enough, I turned an end cap for the spring

and an adaptor for the micro screw

I was going to weld it but in the end it got fitted with grub screws, it works very well.

I have now turned to sorting out the pulley spindle part. I found in the shed an old Mansley cultivator tine shaft real good thick tubing 8-9mm and a couple of good acme threads from some old caravan legs that may come in handy later.

I turned the tubing down .

Today I turned the ends out for a couple of 40mm OD bearing I had, the id of the bearings is approx 17mm so I figure the shaft should be thick enough. I forgot to take a pic

It maybe a while before I get the shaft done, busy time now after the new year, down here the old boys start thinking of the tractor showing season. The phones be busy today already, I may have an interesting project coming in to restore, a 3 wheeled Allis Chalmers which should be interesting.

Cheers Jord

jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

Looking for some advice not done much this week on the build, so today Ive been thinking ahead about motors, I do have a 3 phase motor but thinking I could bring the cutter home and do some sharpening in the evenings, I am looking to go single phase. I am am not to knowledgeable on electric motors but I have found this one on the auction site,

https://www.ebay.co.uk/itm/Single-P...ole-2800-rpm-HP/173988220100?var=472777767326

It is only 0-37kw but has the speed I am looking for, and from what I have found the frame size dont look to big.

Question is would 0-37kw be enough power for my needs ie, I dont want it under powered

Cheers in advance

Jord

https://www.ebay.co.uk/itm/Single-P...ole-2800-rpm-HP/173988220100?var=472777767326

It is only 0-37kw but has the speed I am looking for, and from what I have found the frame size dont look to big.

Question is would 0-37kw be enough power for my needs ie, I dont want it under powered

Cheers in advance

Jord

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,545

- Location

- The Shed of Danger, surrey, England

Looking for some advice not done much this week on the build, so today Ive been thinking ahead about motors, I do have a 3 phase motor but thinking I could bring the cutter home and do some sharpening in the evenings, I am looking to go single phase. I am am not to knowledgeable on electric motors but I have found this one on the auction site,

https://www.ebay.co.uk/itm/Single-P...ole-2800-rpm-HP/173988220100?var=472777767326

It is only 0-37kw but has the speed I am looking for, and from what I have found the frame size dont look to big.

Question is would 0-37kw be enough power for my needs ie, I dont want it under powered

Cheers in advance

Jord

That's twice the motor in a Deckel/clone tool grinder, should be plenty? Expecting to take off more than half a cubic inch per minute?

Dave H. (the other one)

jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

That's twice the motor in a Deckel/clone tool grinder, should be plenty? Expecting to take off more than half a cubic inch per minute?

Dave H. (the other one)

Thanks Dave I bought one tonight

jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

Not a lot done but a little update

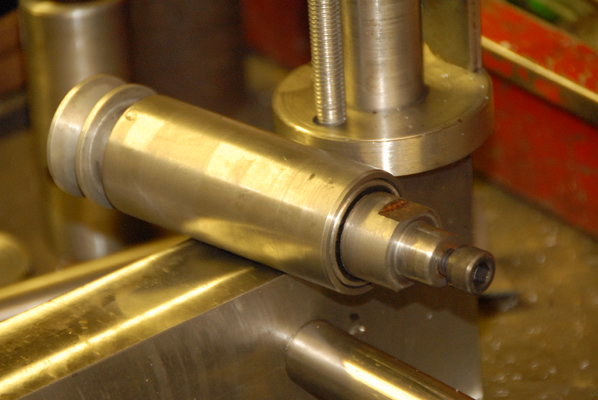

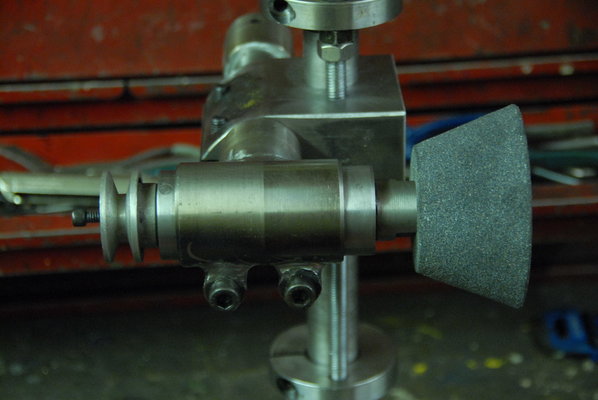

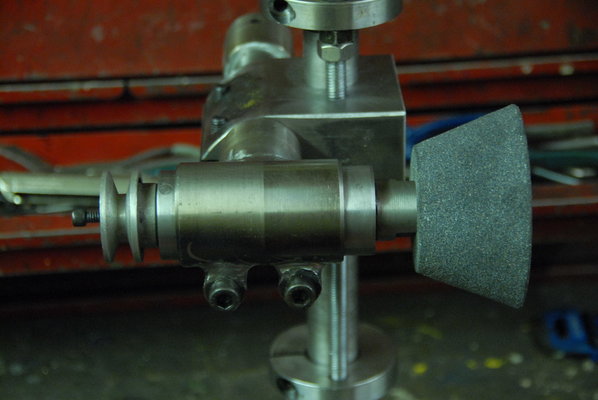

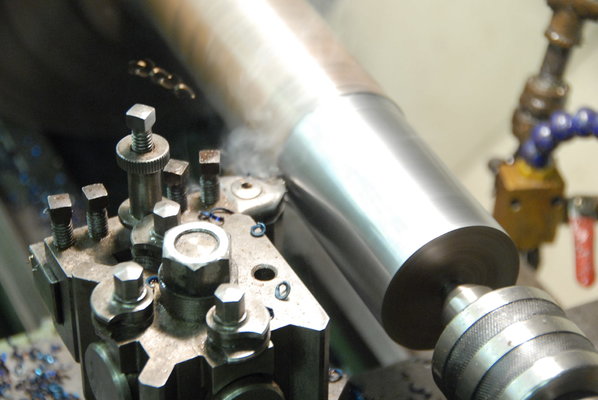

I manage to find an end off cut of the ground boring bar and made the spindle part when turning the spindle shaft I actually kept the spanner end part as it will be handy when changing wheels I had a pulley it just needed boring out to fit.

I used some off cut of the boring head to make the spindle holder and mount and the motor shaft mount. I am actually quite pleased with the way it came out, I ran the milling cutter on it to make some recesses for the tightening parts to be welded on

Once drilled and tapped they are welded on, I then ran a slitting saw through them.

Luckily I have a load of M10 hex head bolts left over from when making my folder fingers so I am using all M10 on this project saves having a number of different size allen keys about. Today I grinded of some of the welds to tidy it up a bit I have run out of flappy disc so will have to wait for a proper tidy up.

I stuck a grinding wheel on for a photo. I just love the angle I can get on this .

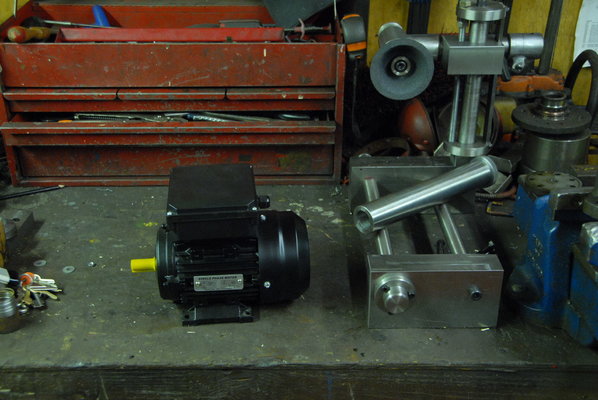

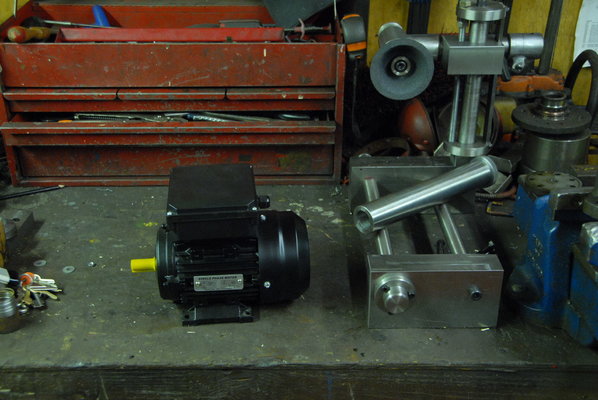

I have ordered a motor today in the end for the extra fiver I went for one of these

Single Phase Electric Motor 0.55kw 2800rpm Frame Size 71 Shaft Size 14mm x 30mm

that will hopefully be here Thursday or Friday and a belt, I have not used this type before but after some research, though I would give it a try, its 10mm polyurethane round drive belting, just melt it and push together hopefully it will save a bit of faffing about, it has a 10% stretch so finger crossed I wont need any tensioners.

I expect that's it till next week on this build unless I cant sleep

Cheers all

Jord

I manage to find an end off cut of the ground boring bar and made the spindle part when turning the spindle shaft I actually kept the spanner end part as it will be handy when changing wheels I had a pulley it just needed boring out to fit.

I used some off cut of the boring head to make the spindle holder and mount and the motor shaft mount. I am actually quite pleased with the way it came out, I ran the milling cutter on it to make some recesses for the tightening parts to be welded on

Once drilled and tapped they are welded on, I then ran a slitting saw through them.

Luckily I have a load of M10 hex head bolts left over from when making my folder fingers so I am using all M10 on this project saves having a number of different size allen keys about. Today I grinded of some of the welds to tidy it up a bit I have run out of flappy disc so will have to wait for a proper tidy up.

I stuck a grinding wheel on for a photo. I just love the angle I can get on this .

I have ordered a motor today in the end for the extra fiver I went for one of these

Single Phase Electric Motor 0.55kw 2800rpm Frame Size 71 Shaft Size 14mm x 30mm

that will hopefully be here Thursday or Friday and a belt, I have not used this type before but after some research, though I would give it a try, its 10mm polyurethane round drive belting, just melt it and push together hopefully it will save a bit of faffing about, it has a 10% stretch so finger crossed I wont need any tensioners.

I expect that's it till next week on this build unless I cant sleep

Cheers all

Jord

jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,545

- Location

- The Shed of Danger, surrey, England

Have you given much thought to the workholder yet? I was thinking of ER32 / ER40 collets if I get the circular tuits, have some chunks of 22mm ground and hard-chromed rod and big ally blocks stashed away, along with a 3/4HP DC motor that I could put a (to be repaired KBIC) speed control on... And some fat stainless that has a lapped-fit rod through that could be an air bearing in another life? Put the two together stood upright trapping air on a greased plate and the rod spins for a couple of minutes with a hand-twist...

I guess you've already found https://www.gadgetbuilder.com/Brooks_Grinder.html, and his 4-facet / split-point drill sharpener that could be sat on it quite easily https://www.gadgetbuilder.com/DrillSharp.html ...

Dave H. (the other one)

I guess you've already found https://www.gadgetbuilder.com/Brooks_Grinder.html, and his 4-facet / split-point drill sharpener that could be sat on it quite easily https://www.gadgetbuilder.com/DrillSharp.html ...

Dave H. (the other one)

jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

I would rather have a flat pulley or poly v pulley on the grinding head than a v pulley for smoother running.

Cheers MBB its a good point, I am using bits I have to hand at the mo if there's vibrations later it wont take no time to knock up a pulley and change belts.

jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

Have you given much thought to the workholder yet? I was thinking of ER32 / ER40 collets if I get the circular tuits, have some chunks of 22mm ground and hard-chromed rod and big ally blocks stashed away, along with a 3/4HP DC motor that I could put a (to be repaired KBIC) speed control on... And some fat stainless that has a lapped-fit rod through that could be an air bearing in another life? Put the two together stood upright trapping air on a greased plate and the rod spins for a couple of minutes with a hand-twist...

I guess you've already found https://www.gadgetbuilder.com/Brooks_Grinder.html, and his 4-facet / split-point drill sharpener that could be sat on it quite easily https://www.gadgetbuilder.com/DrillSharp.html ...

Dave H. (the other one)

Hi Dave Cheers for the links I havent seen them, it sounds like you will be making a grinder yourself soon with all the kit.

Yes I have been thinking about the chucks, I was going to go for the ER32 or the ER40 chuck and collets but during the build process I thought hang on, to save on money, space and storing another set of collects and holders, I have for my milling machine a number of Clarkson Autolock chucks already, both large and small and sets of collets both imperial and metric. I was going to have a go at turning a couple of them down to a straight shank. But then I thought, why not have a go at making the tool head around what I already have, ie make the tool head with a 40 taper. All my tooling for the mill is 40INT taper, I have been watching some videos on how to turn tapers, I watched one last night by doubleboost, which has encouraged me to have a go. If I can pull the 40 taper off, I can then use all the holders from my mill tooling.

I don’t yet know if it is possible, I am thinking turn a hollow shaft approx 300mm with a female 40 taper in one end I am hoping to turn in the other end of the shaft, a female 3 morse taper. I can then make up a 5/8 drawbar to pull the 40 taper in, same fitting as the mill. I did find a while back in the off cut bin at our local agri engineering works a couple of bits of steel I thought might do, there was a piece approx 630mm 60x60 steel square bare and some round bar, about 450mm long I think it was part of an old hydraulic ram 70mm thick,

I tried to cut the round bar in the bandsaw this afternoon, I left it in for a good 20 mins whilst I was doing something else and the saw wouldn't touch it. I did round off some of the square bar later it cuts and turns nice,

so will try and make the tapered tube out of that and look round for something else to make the housing.

Fingers crossed.

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,545

- Location

- The Shed of Danger, surrey, England

Rods out of hydraulics are 'kin hard, usually hard chrome over a hard skin - often cut OK once you're through the first couple of mm, but it's getting that far... cover the lathe with a bedsheet and clamp an angle grinder (weapon of choice!) to the toolpost, 20 rpm?

Dave H. (the other one)

Dave H. (the other one)

jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

Rods out of hydraulics are 'kin hard, usually hard chrome over a hard skin - often cut OK once you're through the first couple of mm, but it's getting that far... cover the lathe with a bedsheet and clamp an angle grinder (weapon of choice!) to the toolpost, 20 rpm?

Dave H. (the other one)

Cheers Dave I will see if I can turn the first couple mm off first.

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,545

- Location

- The Shed of Danger, surrey, England

Are you offsetting the tail stock to cut the taper

30 / 40 Taper's a bit steep for the tailstock offset, a touch over 16 degrees / 3.5" per foot, so either setting the topslide over or taper attachment* if you have one (I should once I've made the shoe for it...), ER 40 / ER 32 are about the same, 16 degrees included...

Dave H. (the other one)

* 30 / 40Taper - in the 4-jaw, indicate concentric, run toolpost back n forth with a DTI and tap topslide or taper slide around until it doesn't budge, got your angle OR the ER 32 / 40 collet on a piece of ground rod in lathe collet / 4-jaw and concentric, same again.

ronan

Member

- Messages

- 11,399

Rods out of hydraulics are 'kin hard, usually hard chrome over a hard skin - often cut OK once you're through the first couple of mm, but it's getting that far... cover the lathe with a bedsheet and clamp an angle grinder (weapon of choice!) to the toolpost, 20 rpm?

Dave H. (the other one)

Chromed steel bar for use in hydraulic rams is usually EN19 in the "T" condition. It is hard but should be workable, especially if you are using tct tools.

There was accompany up here called Cascade who used to make hydraulic rams. I used to get offcuts from them . I think the metal was en 41 but

I cant be sure of that but once I took a cut about .001" to get under the skin it machined ok. I still have some rams lying about.

I cant be sure of that but once I took a cut about .001" to get under the skin it machined ok. I still have some rams lying about.

jordhandson

Member

- Messages

- 1,446

- Location

- Dorset

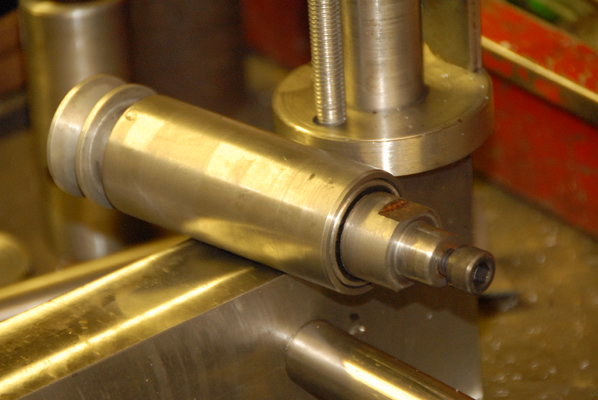

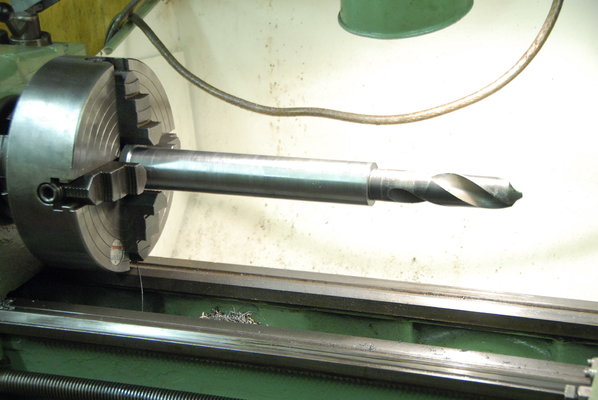

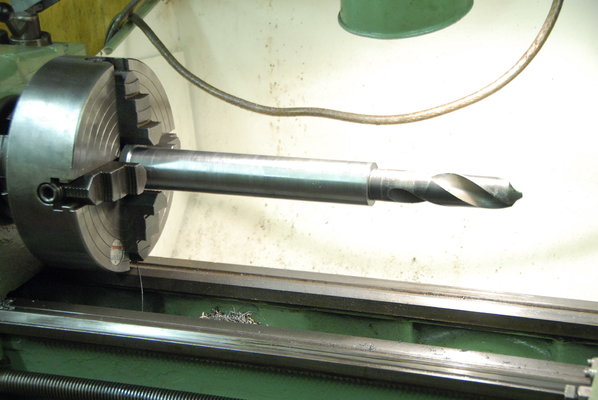

Last night I managed to crack the 40 taper It took me a while to figure it out but got there in the end, I kept forgetting when on the lathe one has to halve the angle if you get what I mean 16 degrees or there about, once I figured out about the half just over 8 degree all fell into place.

The pictures should explain, once I had the 40 taper sorted I turned a 4 morse taper on the other end, as 4 morse is the bigger taper drill I have so figured I can do all under by using reducers.

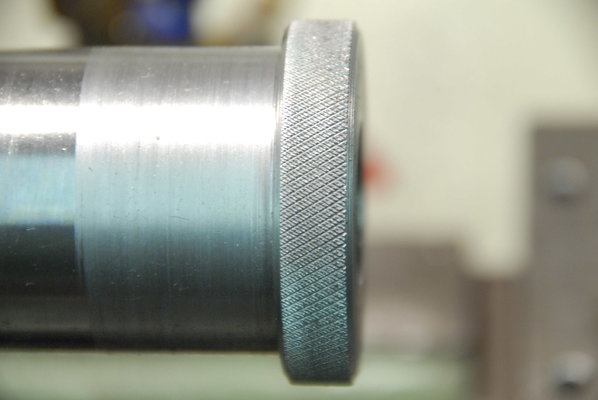

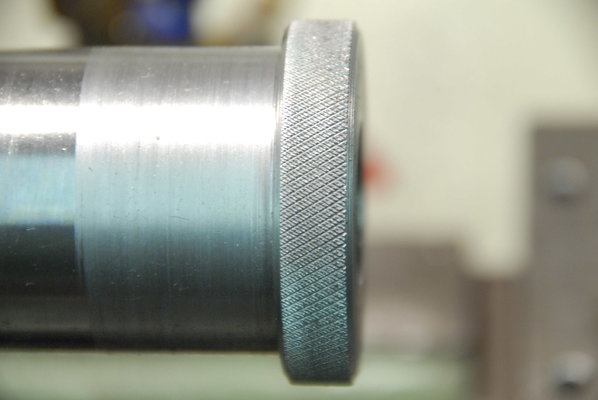

Today I just spent time chasing the elusive mirror finish, Its by no means perfect yet, as when I am taking the bigger cuts my finish is brill, its when I get down to say take 1 of 2 thou I seam to loose the finish, there are a few marks that will polish out as and when I get the other parts done, as I am not yet at my final finish size for the shaft. I did get to use my Jones and Shipman knurling tool I picked up,

I am quite pleaded with it.

I now need to make a 5/8th draw bar, the slide tube then the head as and when, I will probable make a nice end cap with the draw bar screwed in with some knurling on, as I like the finish.

On another note the motor arrived earlier today I reckon its going be a good fit and not to big with plenty of power, 50 odd quid delivered to the door couldn't grumble about the price.

Cheerrs

Jord

The pictures should explain, once I had the 40 taper sorted I turned a 4 morse taper on the other end, as 4 morse is the bigger taper drill I have so figured I can do all under by using reducers.

Today I just spent time chasing the elusive mirror finish, Its by no means perfect yet, as when I am taking the bigger cuts my finish is brill, its when I get down to say take 1 of 2 thou I seam to loose the finish, there are a few marks that will polish out as and when I get the other parts done, as I am not yet at my final finish size for the shaft. I did get to use my Jones and Shipman knurling tool I picked up,

I am quite pleaded with it.

I now need to make a 5/8th draw bar, the slide tube then the head as and when, I will probable make a nice end cap with the draw bar screwed in with some knurling on, as I like the finish.

On another note the motor arrived earlier today I reckon its going be a good fit and not to big with plenty of power, 50 odd quid delivered to the door couldn't grumble about the price.

Cheerrs

Jord