Pete.

Member

- Messages

- 15,070

- Location

- Kent, UK

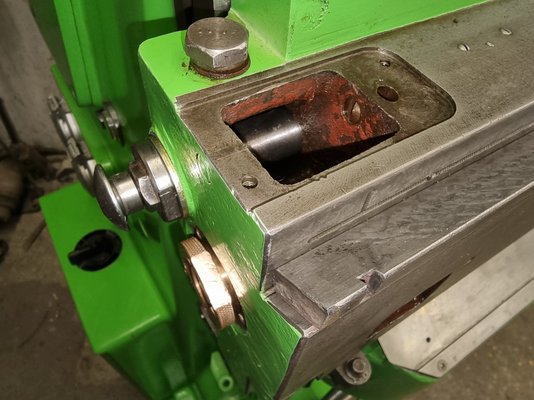

Getting ready to mask and paint the z slide today but I have some scraping and flaking still to do. First I put 3 good scraping passes over one side of the Z slide flat ways. This is to try to correct the very small deviation in the table sweep test. I know that the test was already within spec but I figured since I'm working on it anyway it wouldn't do any harm. It had a good contact pattern and slightly lighter in the middle which it should be. Then I ran the flaker over those ways to increase oil bearing capacity.

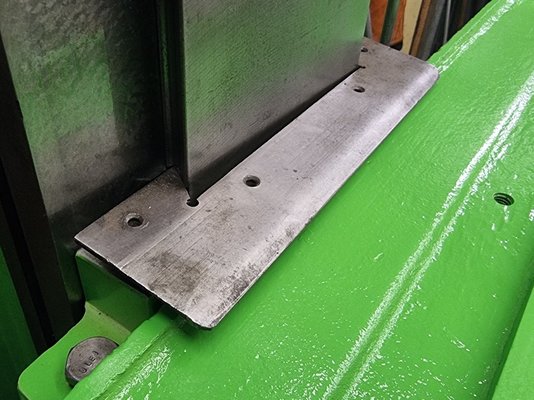

After that I took the Biax flaker and flaked the flat ways of the console table. I went only in one direction, so that I didn't remove too much bearing.

It leaves quite a pleasing pattern but it's not easy to get a good uniform pattern. I'm fairly satisfied with this. Some people are very good at it though usually it will never be seen.

I blued up my 30" straight edge to check the working dovetail on the z slide.

It was pretty healthy in terms of contact and required only minor scraping to get full length contact. I was quite pleased with this as these inside dovetails are a real pain to scrape.

After a hanful of rounds of very awkward scraping I got the contact pattern to a satisfactory level. I wanted to flake this way as it does a lot of work so needs good oil retention. No way the flaker was getting in there so I had to be satisfied with putting 2 rows of very heavy short scrapes down it to create some oil pockets.

So that should be the scraping all done on this machine unless it needs further alignment fettling later. I know that the tee slot sides on the console table are 3 thou out of line with the table travel, but rather than try to scrape that out I will make the adjustments to the keyways on the table as it's a lot of work otherwise for very little gain. I don't envisage fixing parts directly to the console table and if I do I would have to tram them anyway.

After that I took the Biax flaker and flaked the flat ways of the console table. I went only in one direction, so that I didn't remove too much bearing.

It leaves quite a pleasing pattern but it's not easy to get a good uniform pattern. I'm fairly satisfied with this. Some people are very good at it though usually it will never be seen.

I blued up my 30" straight edge to check the working dovetail on the z slide.

It was pretty healthy in terms of contact and required only minor scraping to get full length contact. I was quite pleased with this as these inside dovetails are a real pain to scrape.

After a hanful of rounds of very awkward scraping I got the contact pattern to a satisfactory level. I wanted to flake this way as it does a lot of work so needs good oil retention. No way the flaker was getting in there so I had to be satisfied with putting 2 rows of very heavy short scrapes down it to create some oil pockets.

So that should be the scraping all done on this machine unless it needs further alignment fettling later. I know that the tee slot sides on the console table are 3 thou out of line with the table travel, but rather than try to scrape that out I will make the adjustments to the keyways on the table as it's a lot of work otherwise for very little gain. I don't envisage fixing parts directly to the console table and if I do I would have to tram them anyway.