Hmmm, not a fan for this one - it’s a short gib - 10 inches or so, so any give will be amplified. It’s a new gib or brass shim I reckon.Turcite perhaps?

- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Town Woodhouse milling machine re-commission and cnc conversion

- Thread starter minimutly

- Start date

pressbrake1

Member

- Messages

- 5,709

- Location

- Essex

Shim the gib on the static side and then scrape inI’ve test fitted the carriage on the knee, the gib strip is slack. Do I need a new one or can I glue a strip of brass shim to the one I have, or the dovetail?

@pressbrake1 - any thoughts?

pressbrake1

Member

- Messages

- 5,709

- Location

- Essex

Turcite is soft so needs big surface area

Agree, that’s what I thought, thanks!Turcite is soft so needs big surface area

This is the little blighter:-Agree, that’s what I thought, thanks!

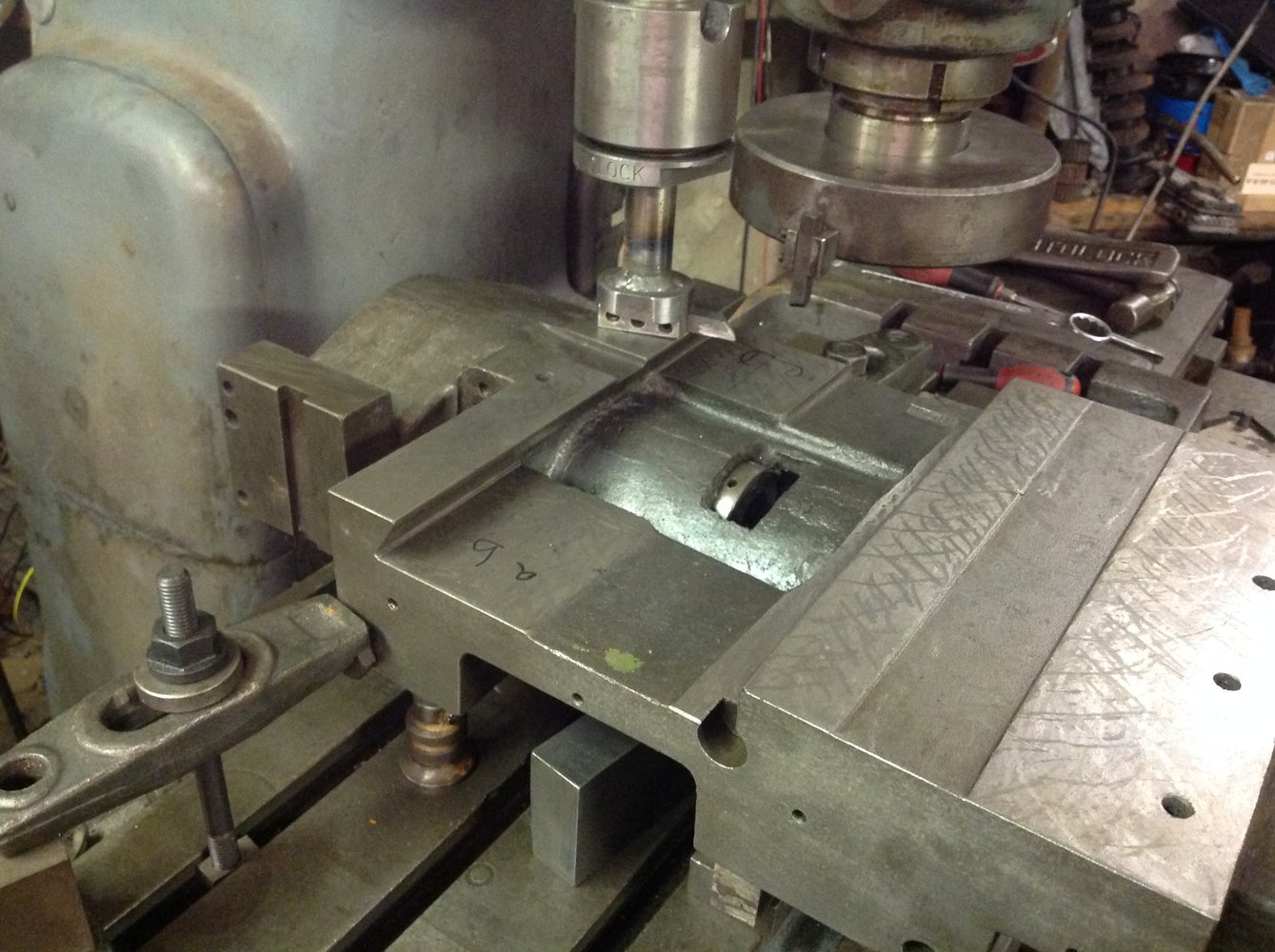

This has been on stop for a while, vying for my time. One of the issues was that the stepped under - face needed dropping 3 thou, so that it fitted the top of the knee. I didn't fance my chances of scraping it, so it needed a flycutter.

After a clean and scrape I tried it - it's close, and any more relieving will be by blueing and scraping.This has been on stop for a while, vying for my time. One of the issues was that the stepped under - face needed dropping 3 thou, so that it fitted the top of the knee. I didn't fance my chances of scraping it, so it needed a flycutter.View attachment 319340View attachment 319341View attachment 319342

This moves the project forward towards deciding on fitting ballscrews or repairing the square thread. A big bit of me wants to put it back as it was and use it, even as an interim to check its accuracy.

Decisions...

Either way it's amazing the amount of progress you have madeAfter a clean and scrape I tried it - it's close, and any more relieving will be by blueing and scraping.

This moves the project forward towards deciding on fitting ballscrews or repairing the square thread. A big bit of me wants to put it back as it was and use it, even as an interim to check its accuracy.

Decisions...

Thanks - I keep telling myself it wil be worth it in the end, and trying to picture it shiny and painted up. It looked like a simple repair (simple?) - but the reallity was that besides the repair needed, the thing was well worn under the layers of dust and rust. Sadly, unless you can use a mill, or strip it, there is no easy way to check for wear, and a layer of rust just hides it.Either way it's amazing the amount of progress you have made

All good learning though, and the scraping course has proved invaluable. Looking forward to making a gear for the notcher.

You're welcome @fizzy - when it's finished!

One of the issues with this was that the users had been greasing all the points, so everything was gummed up with thick grease. The quill feed box was clogged with it, I've yet to make sense of it. Conversely, the table feed box was empty, and the brass drive worm gear wheel worn out. So another journey there to go on.

One of the issues with this was that the users had been greasing all the points, so everything was gummed up with thick grease. The quill feed box was clogged with it, I've yet to make sense of it. Conversely, the table feed box was empty, and the brass drive worm gear wheel worn out. So another journey there to go on.

No pics tonight, but I spent a couple of hours scraping and printing - it's close enough I think, floats around beautifully - except for a spot right as far back as it will go, but I'll need to take the knee casting off to get at that.

When I'd got it somewhere near right, I put it all together dry - it showed the high spots up as shiny, like magic!

When I'd got it somewhere near right, I put it all together dry - it showed the high spots up as shiny, like magic!

I decided to have a go at straightening the vertical column lead screw. First time I did it I found I just couldn't get the press on where I wanted it - the machined on collar was in the way. It ended up like a "z".No pics tonight, but I spent a couple of hours scraping and printing - it's close enough I think, floats around beautifully - except for a spot right as far back as it will go, but I'll need to take the knee casting off to get at that.

When I'd got it somewhere near right, I put it all together dry - it showed the high spots up as shiny, like magic!

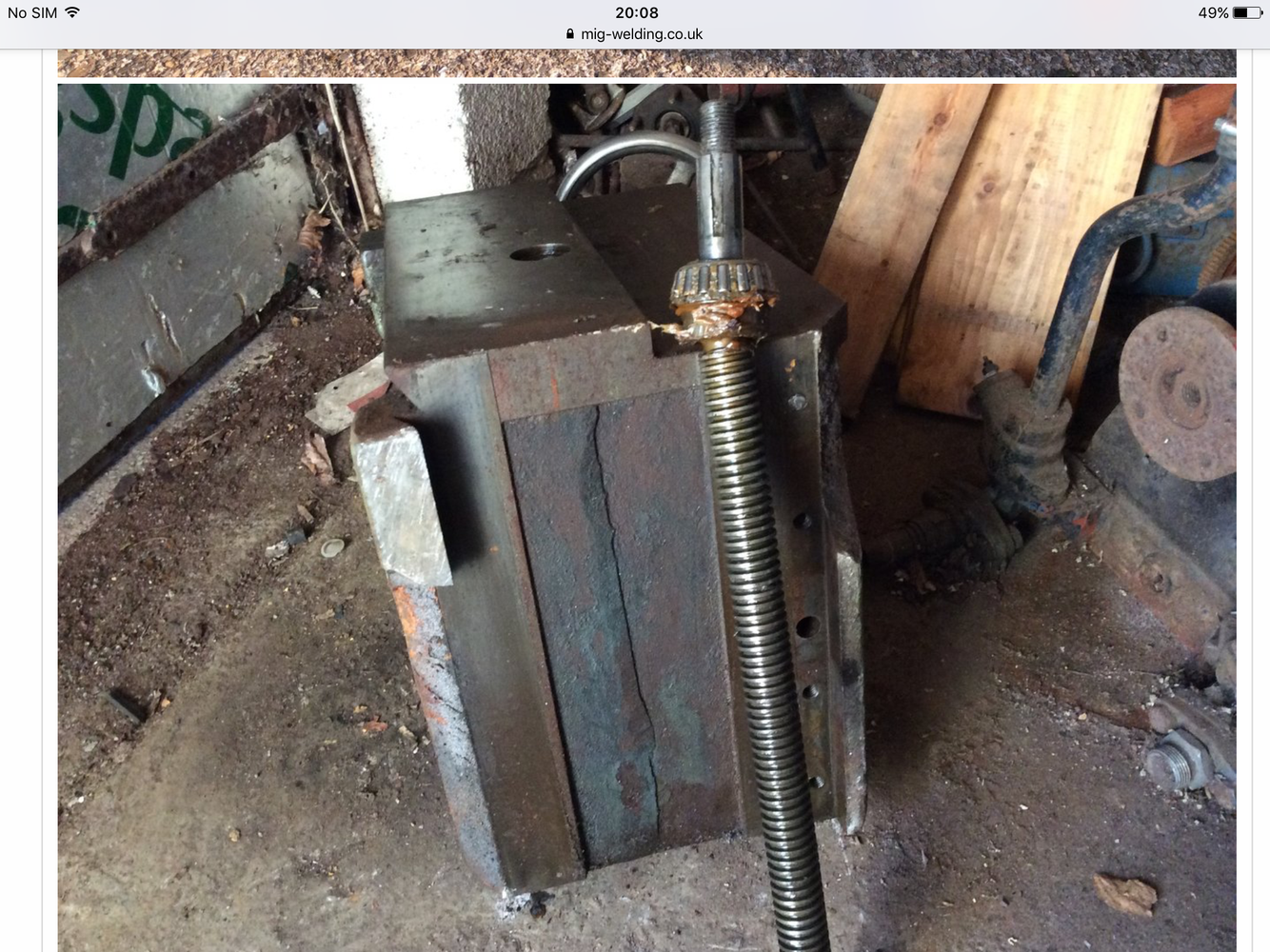

So sh1t or bust, I machined, ground and filed the collar off. Numerous visits to the press, to the lathe to check etc. And it was there. I migged a new collar onto it and machined it back. You guessed it, it had pulled again. So more pressing and checking. Made this:

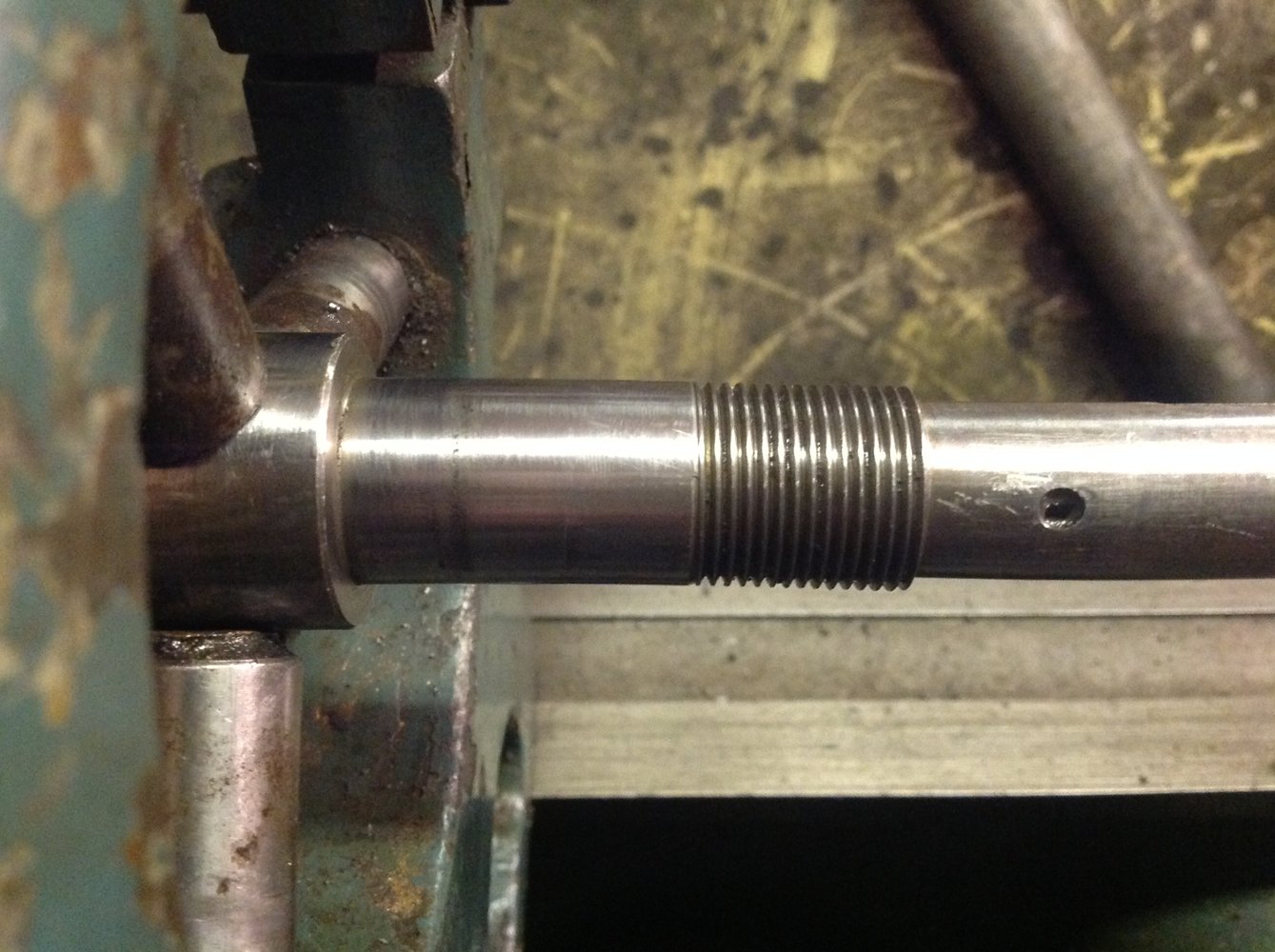

A little fettling of the threads, cleaning and checking, got me this:

First time it's moved up and down for a while I guess. Need to get some shim,to set the gibs, then check the in/out readings before fitting the table. Happy as a dog with two mills..I decided to have a go at straightening the vertical column lead screw. First time I did it I found I just couldn't get the press on where I wanted it - the machined on collar was in the way. It ended up like a "z".

So sh1t or bust, I machined, ground and filed the collar off. Numerous visits to the press, to the lathe to check etc. And it was there. I migged a new collar onto it and machined it back. You guessed it, it had pulled again. So more pressing and checking. Made this: View attachment 320270

A little fettling of the threads, cleaning and checking, got me this: View attachment 320271 View attachment 320272 View attachment 320273 View attachment 320274

Edit to ask - anyone know where to get some brass or other shim - I don't need much, but 22, 32 thou are my targets, so probably some 20, 25 and 30, 35 and some thin stuff.

This is what the knee and z lead screw looked like...

To be honest I should have spent a little more time on truing - there is absolutlely no give between the knee and its double taper bearing and the bronze nut in the pillar. It's not bad though, merest hint of a tight spot as it turns. I shan't worry for now.

To be honest I should have spent a little more time on truing - there is absolutlely no give between the knee and its double taper bearing and the bronze nut in the pillar. It's not bad though, merest hint of a tight spot as it turns. I shan't worry for now.

Yes it is a good feeling to get it moving again, even if I might need to strip it and go back one step. Truth is I'd like to get everything working, do some checks to see if I cocked anything up, and then decide its future. And also get all the bits back onto it so I can re-arrange the furniture in the workshop.Looking like a milling machine again!

Great work.

Been straightening the table lead screw in advance of getting the table scraped in.

Before pics (well after taking a pipe to it to get it apart), hence the compound bend...

After a fair bit of press work

Close enough, no more than 10 though at the handle...

Close enough, no more than 10 though at the handle...

Before pics (well after taking a pipe to it to get it apart), hence the compound bend...

After a fair bit of press work