Dcal

Member

- Messages

- 4,079

- Location

- Antrim Northern Ireland

I built my house in a bog and as a result while I can sort of grow grass, I can grow marvellous rushes.

I'm not into gardening, I just try to keep the worst of the weeds at bay and have some hedges and trees which are all low maintenance.

I put some drainage in 25 odd years ago and I expect it is all clogged now as the rush problem is getting worse and I don’t want to start putting in French drains again.

The problem has been made worse by the even more copious than usual rain fall we have been getting here in the last few years.

I’m not adverse to a bit of chemical warfare and I spray about half a litre of glyphosate weed killer a year.

I don't go full agent orange, I don’t mind letting nature taking over and I have lots of areas left to their own devices.

The rushes that bother me are in the grass (would be a bit of a stretch to call it a lawn) so I can’t spray. There are some systemic weed killers that will deliver the kiss of death to rushes while leaving the grass, moss and weeds alone but I read the SDS and decided to give it a by ball.

Glyphosate will do for them if delivered in a strong enough dose and as the rushes outgrow the grass I thought a wiper would do the job.

I suppose a sponge tied to a stick and a bucket of weed killer would suffice but why go for the sensible option when you can make another tool.

Full disclosure here, I’ve no idea if this will work or is even if it's a good idea.

I made this prototype using whatever I had lying about. (as always)

I started out by thinking of using a continuous rope or wick that ran through a container of weed killer but I couldn’t think of a suitable absorbent rope, so decided on a line of 9 inch paint rollers .

The inside dimension of 9 inch paint rollers sleeves is odd so I ended up using some 11/4" pvc pipe for the roller.

A steel pipe would be far better but this will do for a test.

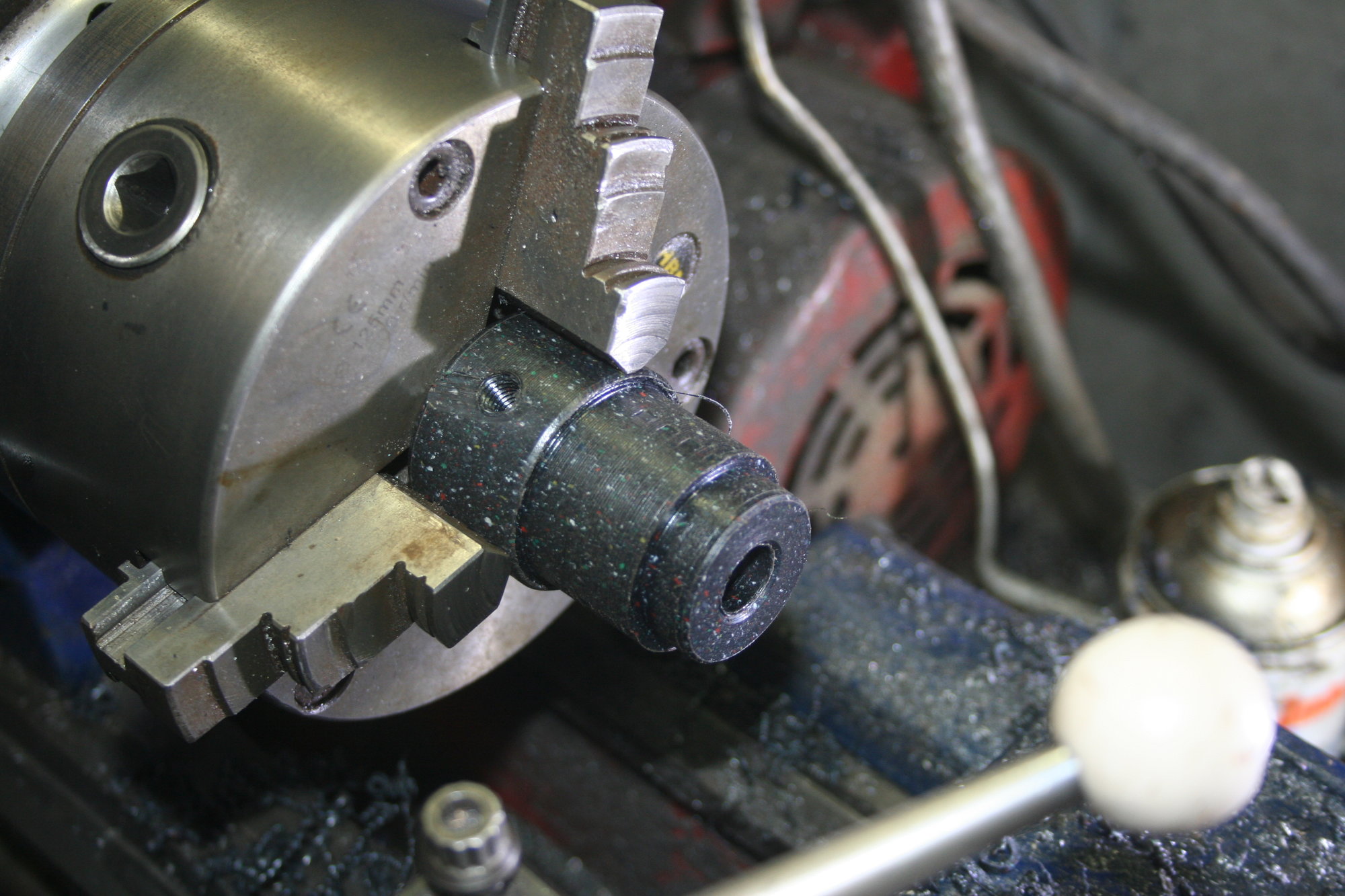

Started by making the bushes and drives for the rollers from UHMWPE.

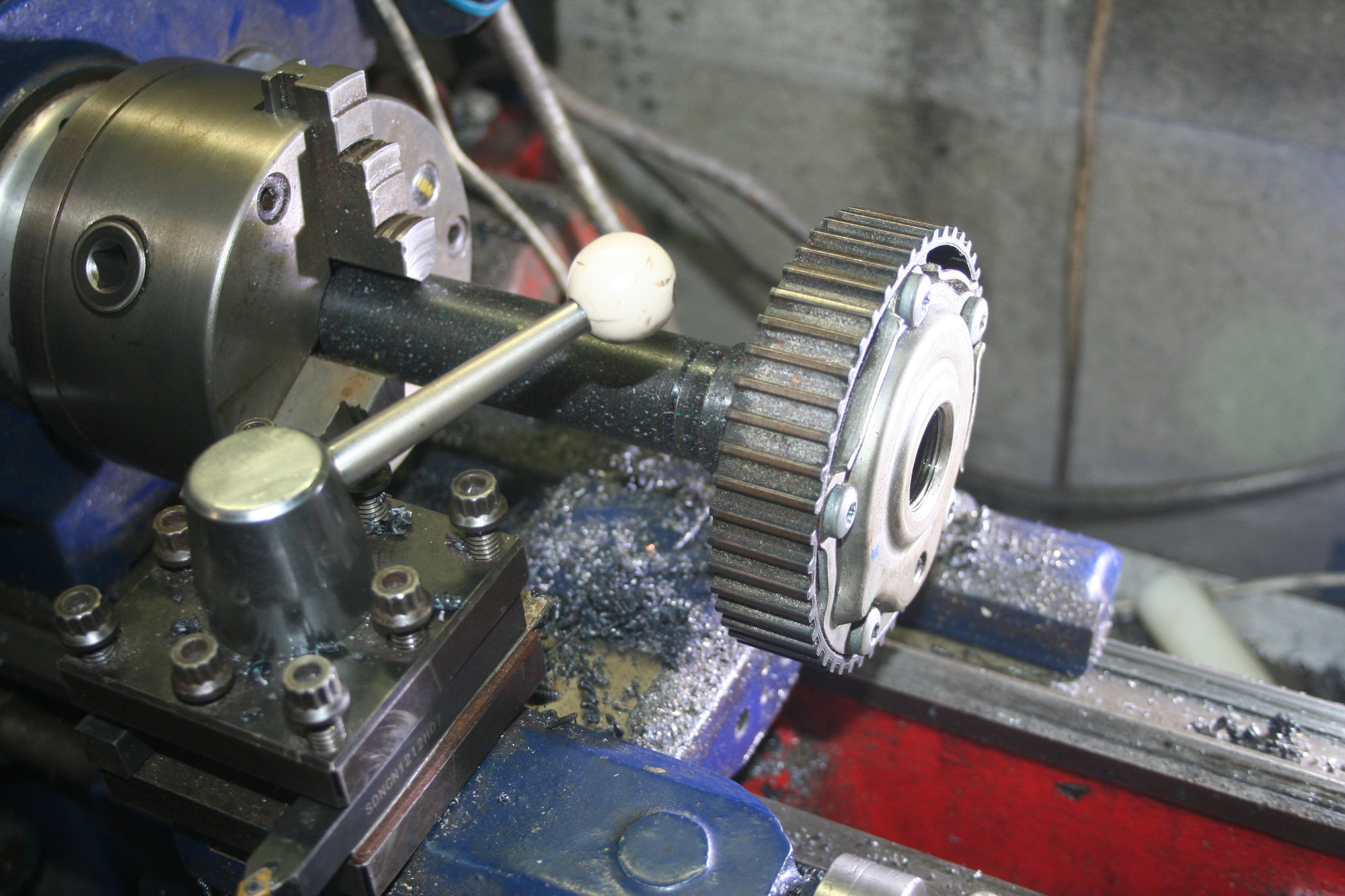

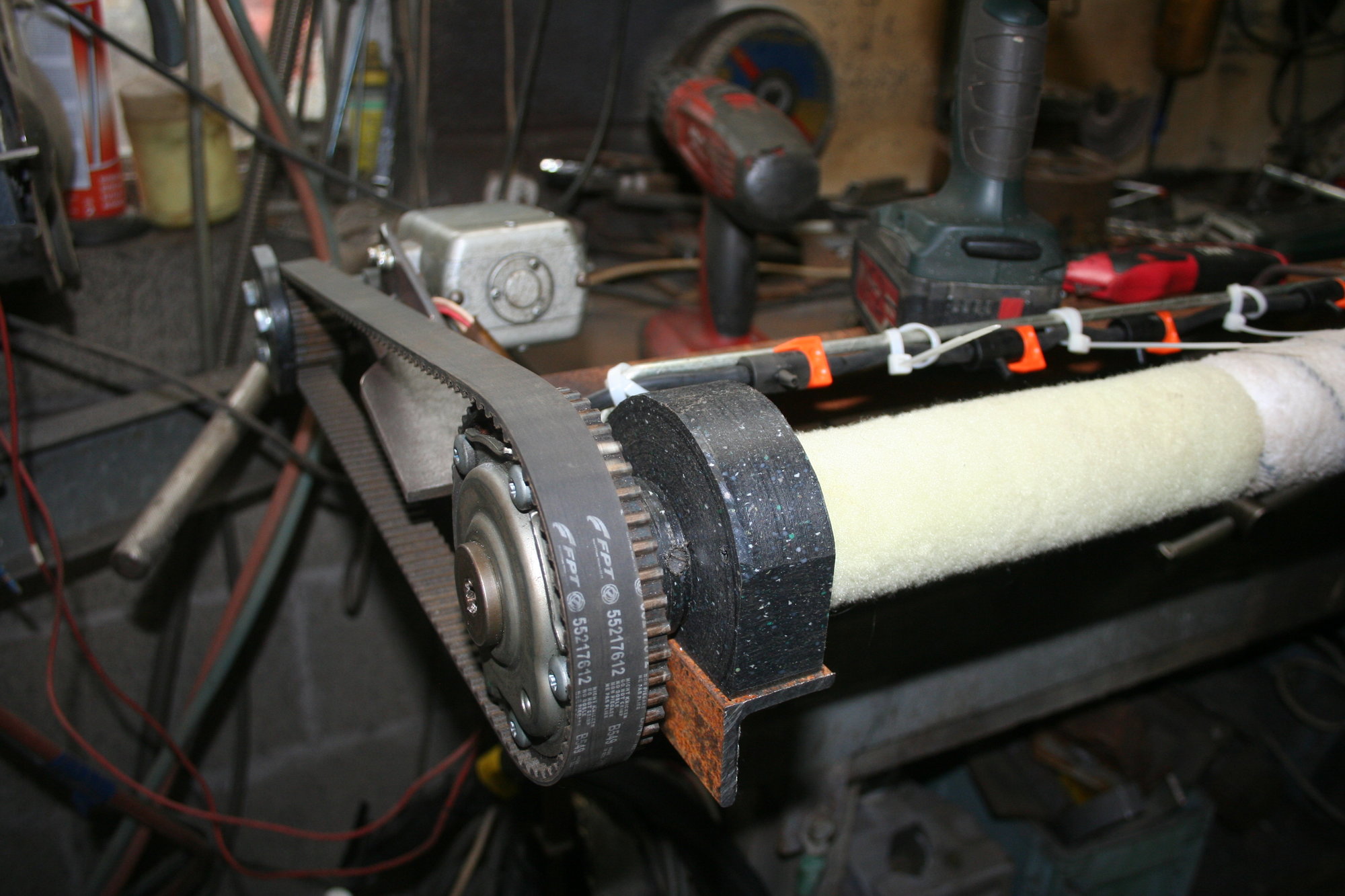

I'd a scrap Fiat engine kicking about so I used the crankshaft and cam pullies for the drive

I also had a wire feeder from a mig I scraped which I used to power it.

For the frame and to mount the motor I used some 2inch angle.

I got the lend of a Bristle Blaster and had a play on the rusty angle and have to say I'm very impressed.

Spot the mistake where I made the adjuster slot on the wrong end and had to weld it up again.

Added a gusset to put back some of the strength from the angle I had to chop to give clearance for the belt.

Trial assembly to see how it fits,

I'm not into gardening, I just try to keep the worst of the weeds at bay and have some hedges and trees which are all low maintenance.

I put some drainage in 25 odd years ago and I expect it is all clogged now as the rush problem is getting worse and I don’t want to start putting in French drains again.

The problem has been made worse by the even more copious than usual rain fall we have been getting here in the last few years.

I’m not adverse to a bit of chemical warfare and I spray about half a litre of glyphosate weed killer a year.

I don't go full agent orange, I don’t mind letting nature taking over and I have lots of areas left to their own devices.

The rushes that bother me are in the grass (would be a bit of a stretch to call it a lawn) so I can’t spray. There are some systemic weed killers that will deliver the kiss of death to rushes while leaving the grass, moss and weeds alone but I read the SDS and decided to give it a by ball.

Glyphosate will do for them if delivered in a strong enough dose and as the rushes outgrow the grass I thought a wiper would do the job.

I suppose a sponge tied to a stick and a bucket of weed killer would suffice but why go for the sensible option when you can make another tool.

Full disclosure here, I’ve no idea if this will work or is even if it's a good idea.

I made this prototype using whatever I had lying about. (as always)

I started out by thinking of using a continuous rope or wick that ran through a container of weed killer but I couldn’t think of a suitable absorbent rope, so decided on a line of 9 inch paint rollers .

The inside dimension of 9 inch paint rollers sleeves is odd so I ended up using some 11/4" pvc pipe for the roller.

A steel pipe would be far better but this will do for a test.

Started by making the bushes and drives for the rollers from UHMWPE.

I'd a scrap Fiat engine kicking about so I used the crankshaft and cam pullies for the drive

I also had a wire feeder from a mig I scraped which I used to power it.

For the frame and to mount the motor I used some 2inch angle.

I got the lend of a Bristle Blaster and had a play on the rusty angle and have to say I'm very impressed.

Spot the mistake where I made the adjuster slot on the wrong end and had to weld it up again.

Added a gusset to put back some of the strength from the angle I had to chop to give clearance for the belt.

Trial assembly to see how it fits,