- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wellsaw 4" mechanical hacksaw

- Thread starter Pete.

- Start date

Shox Dr

Chief Engineer to Carlos Fandango

- Messages

- 18,000

- Location

- East Yorkshire

Im not knocking you. More respecting your talent and abilities to make something the best it can be.Scraping is the best way to ensure the slides stay oiled. Machine depends on that so it makes sense.

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,605

- Location

- North Kent, UK

Surprisingly I found the blades straight away!

Johnnybravo

Member

- Messages

- 3,609

- Location

- Northiam

If there are any blades looking to be rehomed, they would fit mine

Johnnybravo

Member

- Messages

- 3,609

- Location

- Northiam

Pete.

Member

- Messages

- 14,538

- Location

- Kent, UK

What thickness carbide and do you normally need to relieve the bottom of the 'V'?

Sorry I missed out replying to these two question.

I use the sandvik inserts they are 2.25mm thick I. And yes I do relieve the corner of the vee, you pretty much have to. I have a special tool for doing it, which is quite topical for this thread

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,605

- Location

- North Kent, UK

Sorry to get your hopes up, but they also fit my old Manchester saw. Or at least they will do when I put it back together again!If there are any blades looking to be rehomed, they would fit mine

Johnnybravo

Member

- Messages

- 3,609

- Location

- Northiam

Not a problem. Will buy someSorry to get your hopes up, but they also fit my old Manchester saw. Or at least they will do when I put it back together again!

Pete.

Member

- Messages

- 14,538

- Location

- Kent, UK

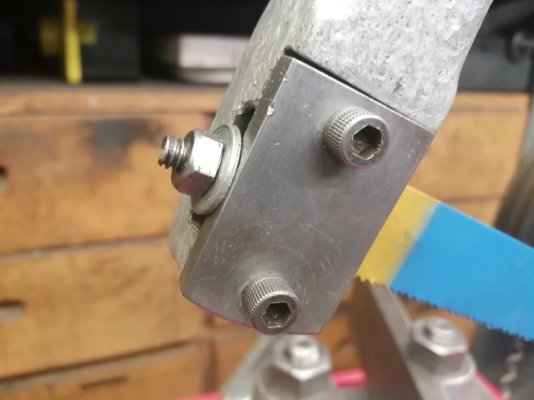

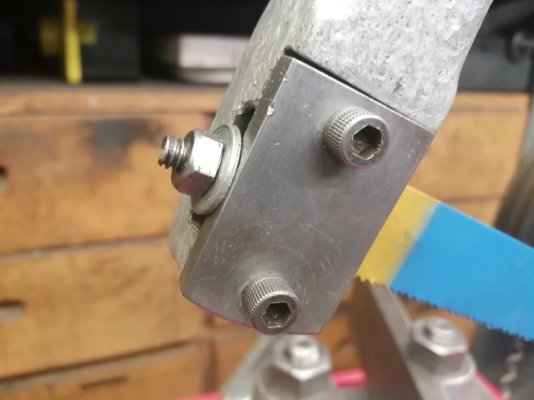

The thread on the blade tensioner was snapped so I drilled and tapped the sliding block and fitted a new one. I also tapped the holes for the clamp plate so I could use 1/4" BSW socket caps instead of the spindly screw and nut arrangement it had previously.

Works properly now, and looks better too.

I spent a bit of time to find two nuts the same size so you only need one spanner to change the blade. BSW nuts are a bit thin on the ground in my workshop

Works properly now, and looks better too.

I spent a bit of time to find two nuts the same size so you only need one spanner to change the blade. BSW nuts are a bit thin on the ground in my workshop

brightspark

Member

- Messages

- 40,427

- Location

- yarm stockton on tees

i have some i bought from autojumble 3 quid a piece 14 inch for rapidor if u want some . dunno what postage is mindNot a problem. Will buy some

brightspark

Member

- Messages

- 40,427

- Location

- yarm stockton on tees

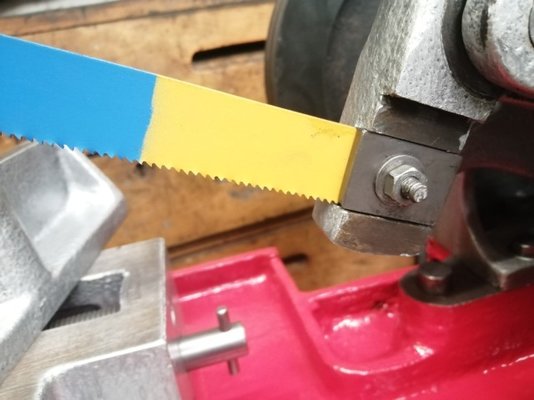

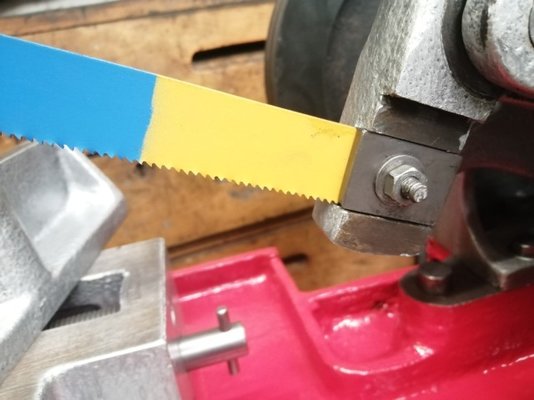

your blade is in reverse  there normaly forward .they are on the rapidor

there normaly forward .they are on the rapidor

there normaly forward .they are on the rapidor

there normaly forward .they are on the rapidorPete.

Member

- Messages

- 14,538

- Location

- Kent, UK

your blade is in reversethere normaly forward .they are on the rapidor

Apparently some cut on the pull stroke but you're right, this one cuts on the push. When you reciprocate the bow you see that the front of the blade is held higher than the rear. Presumably this is so that the damper can hold the teeth off the cut on the back stroke.

Pete.

Member

- Messages

- 14,538

- Location

- Kent, UK

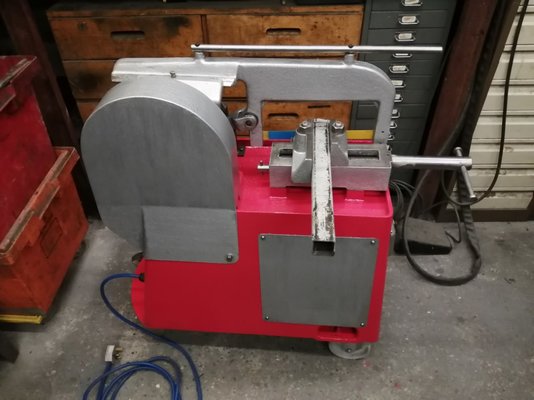

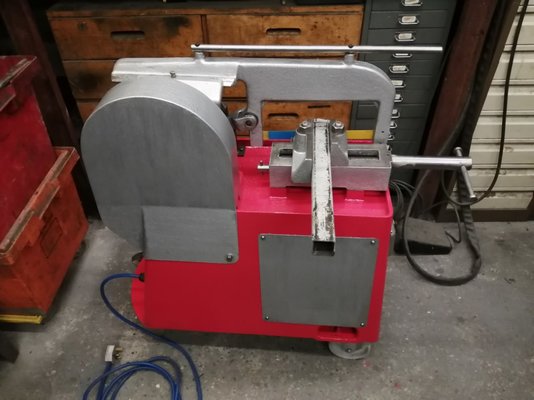

The saw is back together and running. Make very nice tidy cuts, I tested it on some box section.

I do have a few small jobs and some teething problems to sort:

The 415V starter does not like the 240V motor, have to look at that probably disable the overload.

Fit the weight on the bow, I left it of for a test because it's sat on flimsy castors

Set up the oil damper

Recess the bottom faces of both of the vice jaws for better clamping. Right now they can turn too easily even when tight.

Find some better (braked) castors so that it doesn't dance all over the floor. Even without the weight fitted it was walking about the place.

Scrape in the remaining faces on the sliding ways. The geometry is good I just want the faces straightened up and retaining oil.

I do have a few small jobs and some teething problems to sort:

The 415V starter does not like the 240V motor, have to look at that probably disable the overload.

Fit the weight on the bow, I left it of for a test because it's sat on flimsy castors

Set up the oil damper

Recess the bottom faces of both of the vice jaws for better clamping. Right now they can turn too easily even when tight.

Find some better (braked) castors so that it doesn't dance all over the floor. Even without the weight fitted it was walking about the place.

Scrape in the remaining faces on the sliding ways. The geometry is good I just want the faces straightened up and retaining oil.

brightspark

Member

- Messages

- 40,427

- Location

- yarm stockton on tees

nice job the contactor coil will be 415 volt and hardly pull in on 240v its either a new starter or a 240v coil if its worth it and available;e

Pete.

Member

- Messages

- 14,538

- Location

- Kent, UK

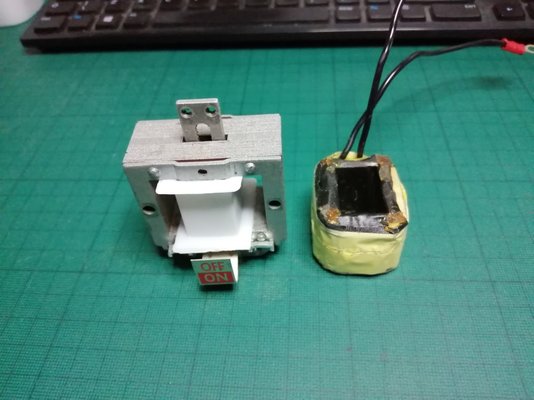

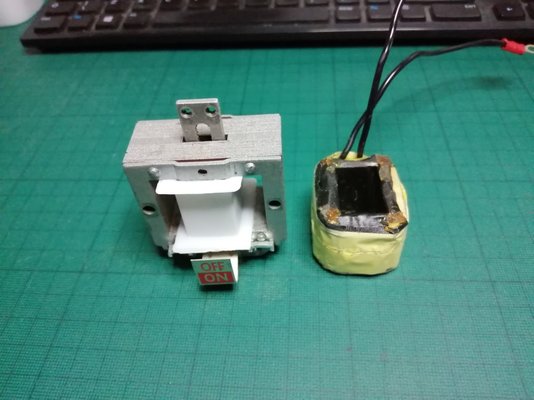

I ended up winding a new coil for this contactor. The lead wire had broken off the winding, which I re-soldered but I found that the coil was very weak to pull in, not surprising since it's supposed to be fed with 415v and I'm only giving it 240v.

So I 3d printed a bobbin to fit the hole in the contactor:

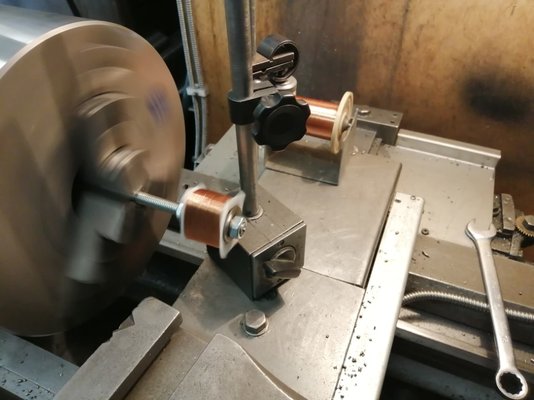

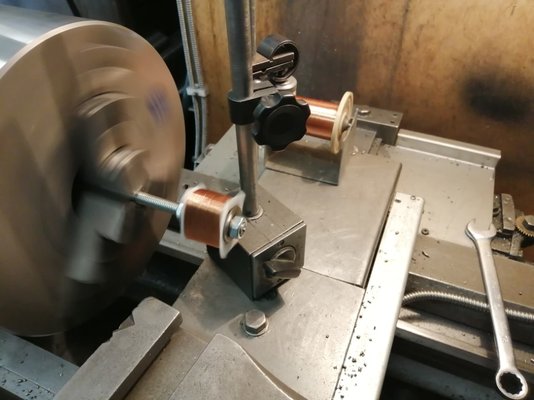

Then I would it full of 0.112mm diameter enammeled wire on my patented coil winding setup

I soldered some leads onto the winding and taped it up temporaily for a test. Fitted the new coil into the contactor and it works like a charm.

Contactor test

Just got to remove it again and impregnate the windings to stop them rubbing and shorting out.

So I 3d printed a bobbin to fit the hole in the contactor:

Then I would it full of 0.112mm diameter enammeled wire on my patented coil winding setup

I soldered some leads onto the winding and taped it up temporaily for a test. Fitted the new coil into the contactor and it works like a charm.

Contactor test

Just got to remove it again and impregnate the windings to stop them rubbing and shorting out.

Brad93

Member

- Messages

- 18,580

- Location

- Essex, United Kingdom

Could of picked you up a winding machine the other weekI ended up winding a new coil for this contactor. The lead wire had broken off the winding, which I re-soldered but I found that the coil was very weak to pull in, not surprising since it's supposed to be fed with 415v and I'm only giving it 240v.

So I 3d printed a bobbin to fit the hole in the contactor:

View attachment 283721

Then I would it full of 0.112mm diameter enammeled wire on my patented coil winding setup

View attachment 283722

I soldered some leads onto the winding and taped it up temporaily for a test. Fitted the new coil into the contactor and it works like a charm.

Contactor test

Just got to remove it again and impregnate the windings to stop them rubbing and shorting out.

Brad93

Member

- Messages

- 18,580

- Location

- Essex, United Kingdom

I need a new 415v coil for a Schneider starter but RS components want £35I ended up winding a new coil for this contactor. The lead wire had broken off the winding, which I re-soldered but I found that the coil was very weak to pull in, not surprising since it's supposed to be fed with 415v and I'm only giving it 240v.

So I 3d printed a bobbin to fit the hole in the contactor:

View attachment 283721

Then I would it full of 0.112mm diameter enammeled wire on my patented coil winding setup

View attachment 283722

I soldered some leads onto the winding and taped it up temporaily for a test. Fitted the new coil into the contactor and it works like a charm.

Contactor test

Just got to remove it again and impregnate the windings to stop them rubbing and shorting out.

Pete.

Member

- Messages

- 14,538

- Location

- Kent, UK

I need a new 415v coil for a Schneider starter but RS components want £35

I've got a 415v starter somewhere I think. Never use them.