- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

Kram

Member

- Messages

- 7,372

- Location

- Sussex

And today no problem

Got to 10mm depth with a chinese 6mm then swapped to The Hydra - this is the same cutter I tried to mill chrome plated bar with and not blunt yet. It is labled PM Co 10.5, not ordinary HSS. I do most of my milling with this. If it ever wears out I have 4 more

Got to 10mm depth with a chinese 6mm then swapped to The Hydra - this is the same cutter I tried to mill chrome plated bar with and not blunt yet. It is labled PM Co 10.5, not ordinary HSS. I do most of my milling with this. If it ever wears out I have 4 more

zx9

Forum Supporter

- Messages

- 5,179

- Location

- South East London

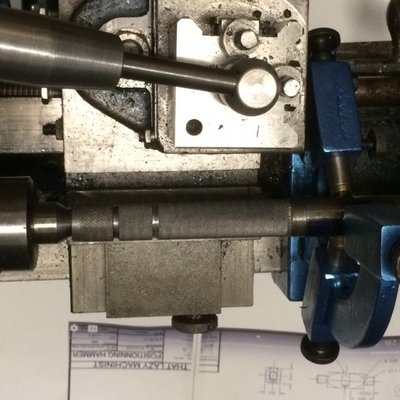

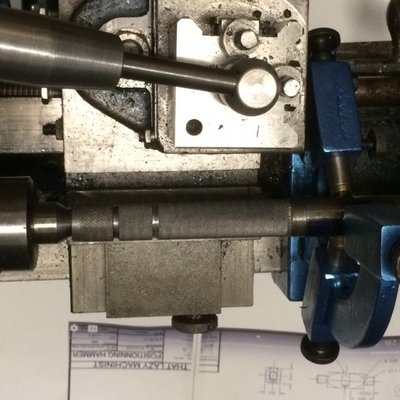

I might have bitten off more than I can chew!

Looking for something useful to make I decided to have a go at a positioning hammer as in this series of videos.

I did underestimate how much more difficult it would be using a 3 1/2" Drummond, his lathe can take 19mm through the spindle, mine well lets just say I am having to use the fixed steady a lot, making set up and tool positioning a lot harder. Next step is turning between centres and then turning a long taper, of cause he uses the taper attachment, me it will be offset tail stock.

Just toying with turning off the first 6mm of knurl which is not so deep as the rest but I think I will just leave it as is.

Edit: More posts to follow as I progress.

Looking for something useful to make I decided to have a go at a positioning hammer as in this series of videos.

I did underestimate how much more difficult it would be using a 3 1/2" Drummond, his lathe can take 19mm through the spindle, mine well lets just say I am having to use the fixed steady a lot, making set up and tool positioning a lot harder. Next step is turning between centres and then turning a long taper, of cause he uses the taper attachment, me it will be offset tail stock.

Just toying with turning off the first 6mm of knurl which is not so deep as the rest but I think I will just leave it as is.

Edit: More posts to follow as I progress.

zx9

Forum Supporter

- Messages

- 5,179

- Location

- South East London

I really don't know how you cope with that, I have seen perspex / polycarbonate screens about a4 size positioned on mag mounts, might be worth your while to make something similar.Face milling with the work towards you. This launches blue hot chips upwards. And down the back of the neck!

My hot chips learning curve extended to burning both fore arms yesterday after discovering that ground HSS can take much deeper interrupted cuts than the inserts I have been destroying in the past.

grim_d

Unlikeable idiot.

- Messages

- 4,263

- Location

- Scotland - Ayrshire

I really don't know how you cope with that, I have seen perspex / polycarbonate screens about a4 size positioned on mag mounts, might be worth your while to make something similar.

My hot chips learning curve extended to burning both fore arms yesterday after discovering that ground HSS can take much deeper interrupted cuts than the inserts I have been destroying in the past.

I actually put the chuck guard back on recently to cut down on chips spraying everywhere. They make a right mess.

Delrin and brass are the worst.

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

Delrin makes a mess? surely not  Good thing though it is easily cleaned up. Brass however is a PITA, months later you will still be getting stabbed with the wee needles.

Good thing though it is easily cleaned up. Brass however is a PITA, months later you will still be getting stabbed with the wee needles.

Best thing for it is to have a CNC, the same mess but all contained

Good thing though it is easily cleaned up. Brass however is a PITA, months later you will still be getting stabbed with the wee needles.

Good thing though it is easily cleaned up. Brass however is a PITA, months later you will still be getting stabbed with the wee needles.Best thing for it is to have a CNC, the same mess but all contained

mtt.tr

Member

- Messages

- 8,436

- Location

- Essex/Suffolk border

Delrin makes a mess? surely notGood thing though it is easily cleaned up. Brass however is a PITA, months later you will still be getting stabbed with the wee needles.

View attachment 229025 View attachment 229026

Best thing for it is to have a CNC, the same mess but all contained

View attachment 229027

I remember when i was in the cabinet shop some how we ended up drilling plates of delrin can't remember the context or why now.

Standing at a fobco using a forster bit for a day was an awful mess.

Though vacuuming up was easier.

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

I actually love working with Delrin, well usually Acetal but basically the same. It cuts nice and although it makes a mess, as you say, it vacuums up easily. You can take massive cuts, the depth of which is limited by the insert edge length, so with a DNMG 15**** that is a lot off the dia in one hit  Only downside is if you need tight tolerances it can take a bit of work, these had to be +0/-0.02 for some strange reason, in fact I had to actually redo one because although it wasn't out of tol the tube was. Normally I measure the tube and make to suite but I was told to make to drawings so that is what I did.

Only downside is if you need tight tolerances it can take a bit of work, these had to be +0/-0.02 for some strange reason, in fact I had to actually redo one because although it wasn't out of tol the tube was. Normally I measure the tube and make to suite but I was told to make to drawings so that is what I did.

Nylon however I hate, horrible bleeding stuff that will slice your fingers off if you are stupid enough to get in the way of the stringers getting wrapped round a chuck. I have had tools pulled out of the turret before with nylon.

On the CNC it is not too bad as you are out of the way.

Only downside is if you need tight tolerances it can take a bit of work, these had to be +0/-0.02 for some strange reason, in fact I had to actually redo one because although it wasn't out of tol the tube was. Normally I measure the tube and make to suite but I was told to make to drawings so that is what I did.

Only downside is if you need tight tolerances it can take a bit of work, these had to be +0/-0.02 for some strange reason, in fact I had to actually redo one because although it wasn't out of tol the tube was. Normally I measure the tube and make to suite but I was told to make to drawings so that is what I did.Nylon however I hate, horrible bleeding stuff that will slice your fingers off if you are stupid enough to get in the way of the stringers getting wrapped round a chuck. I have had tools pulled out of the turret before with nylon.

On the CNC it is not too bad as you are out of the way.

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

You are either a sadist or you do not do much cast.I love machining brass but cast iron is my favourite.

Why are they both so damn expensive though

(edit, should be masochist I think although you may be both

(edit, should be masochist I think although you may be both  )

) I used to do a lot of hauler plates on the manual lathe and had to wear welding gauntlets whilst cutting the face tapers with the compound slide. Now I do them on the CNC and the worst part is cleaning up afterwards as cast iron is not the best for a lathe and also will set like concrete if flood coolant is used and it is not cleaned up right away.

This is the small ones I do, 13" , most now are bigger, 17" and 19"

You are either a sadist or you do not do much cast.

I used to do a lot of hauler plates on the manual lathe and had to wear welding gauntlets whilst cutting the face tapers with the compound slide. Now I do them on the CNC and the worst part is cleaning up afterwards as cast iron is not the best for a lathe and also will set like concrete if flood coolant is used and it is not cleaned up right away.

This is the small ones I do, 13" , most now are bigger, 17" and 19"

I have only ever machined nice high quality free cutting cast iron.

And I thought it should always be done dry?

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

Dry is the normal way on a manual lathe but flood helps control the mess on the CNC.I have only ever machined nice high quality free cutting cast iron.

And I thought it should always be done dry?

mtt.tr

Member

- Messages

- 8,436

- Location

- Essex/Suffolk border

I actually love working with Delrin, well usually Acetal but basically the same. It cuts nice and although it makes a mess, as you say, it vacuums up easily. You can take massive cuts, the depth of which is limited by the insert edge length, so with a DNMG 15**** that is a lot off the dia in one hitOnly downside is if you need tight tolerances it can take a bit of work, these had to be +0/-0.02 for some strange reason, in fact I had to actually redo one because although it wasn't out of tol the tube was. Normally I measure the tube and make to suite but I was told to make to drawings so that is what I did.

View attachment 229029

Nylon however I hate, horrible bleeding stuff that will slice your fingers off if you are stupid enough to get in the way of the stringers getting wrapped round a chuck. I have had tools pulled out of the turret before with nylon.

On the CNC it is not too bad as you are out of the way.

View attachment 229030

I remember my first go drilling nylon, near knocked my self out with the fumes.

At that tender age might explain somethings lol

Hood

I am obsessed.

- Messages

- 17,460

- Location

- Carnoustie, Scotland

Nylon fumes are not bad, Delrin/Aceatl however are a bit potent. Worst thing is if it catches fire you don't notice until the fumes hit your airways and nearly choke you to death. You can hardly see the Delrin/Acetal burning as it is a tiny surface flame and not noticeable, well until you breath it that is.I remember my first go drilling nylon, near knocked my self out with the fumes.

At that tender age might explain somethings lol

I learned my lesson years ago, had a stainless bin full of Acetal swarf and had been welding nearby, eyes started to stream and started choking, couldn't see the flames but knew what it was right away so threw a soaked cloth over the bin then dumped a bucket of water in it

BTW that is an easy way to identify Delrin/Acetal, put a lighter to the edge then have a quick sniff, you will soon know if it is or isn't

mtt.tr

Member

- Messages

- 8,436

- Location

- Essex/Suffolk border

Nylon fumes are not bad, Delrin/Aceatl however are a bit potent. Worst thing is if it catches fire you don't notice until the fumes hit your airways and nearly choke you to death. You can hardly see the Delrin/Acetal burning as it is a tiny surface flame and not noticeable, well until you breath it that is.

I learned my lesson years ago, had a stainless bin full of Acetal swarf and had been welding nearby, eyes started to stream and started choking, couldn't see the flames but knew what it was right away so threw a soaked cloth over the bin then dumped a bucket of water in it

BTW that is an easy way to identify Delrin/Acetal, put a lighter to the edge then have a quick sniff, you will soon know if it is or isn't

I have such poor sense of smell when i can finally smell something i get an almost immediate headache.