- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Machining Techniques and Materials

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are you machining?

- Thread starter Kram

- Start date

Brad93

Member

- Messages

- 19,430

- Location

- Essex, United Kingdom

That’s a nice Kearns!Repairs to a bearing housing on a gearbox casting.

rory1

Member

- Messages

- 1,200

- Location

- Macclesfield

That’s a nice Kearns!

me and that borer have a Turbulent relationship. I love it but it hates me and insists that I keep spending money on it.

Pete.

Member

- Messages

- 15,070

- Location

- Kent, UK

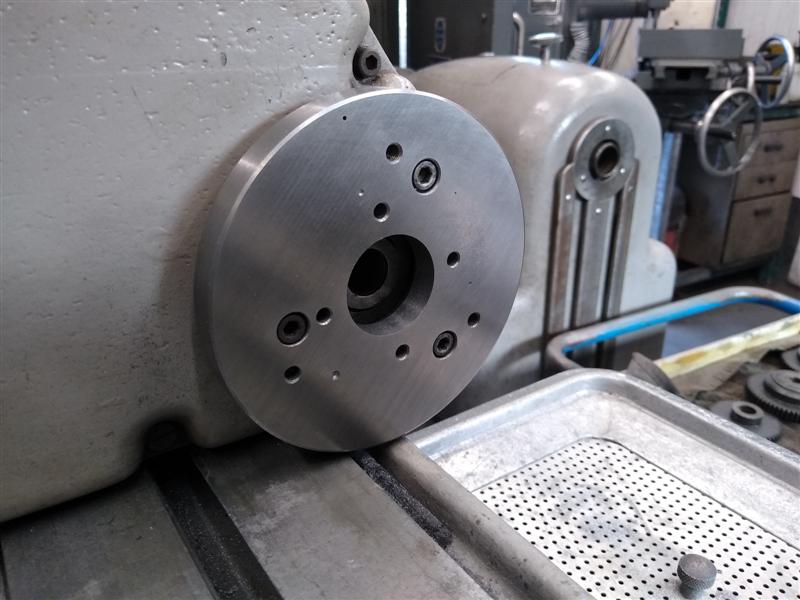

I made a 5" backplate with a loose register to mount different chucks to my cylindrical grinder. Here it is drilled for a 4" 3-jaw Burnerd chuck and a pre-drilled for a 3" 4-jaw, and spotted for the original 80mm Pratt chuck. No register at all for the chuck backs.

Brad93

Member

- Messages

- 19,430

- Location

- Essex, United Kingdom

I bet, gotta be 40-50 years old and there’s a lot going on in a borer.me and that borer have a Turbulent relationship. I love it but it hates me and insists that I keep spending money on it.

Where did you find it? I keep my eye out but never see smaller kearns come up.

ronan

Member

- Messages

- 11,382

me and that borer have a Turbulent relationship. I love it but it hates me and insists that I keep spending money on it.

I have found machine tools are like that, they are like kids, landrovers or taxes, you are never done paying for them.

Agroshield

Member

- Messages

- 6,394

Repairs to a bearing housing on a gearbox casting.

Would you have any insight into why some borers are right hand headstock like your own (and the one Brian Block has) and others are left hand headstock (like El metal Raymond and the one Abom used to use)? Thanks.

Brad93

Member

- Messages

- 19,430

- Location

- Essex, United Kingdom

Tad bigger than the Union/MWM machine they had where I worked.It’s was on an online auction, non runner as it had a gear broken in the head. It’s an Sh75 with a 1m square table. Weights just under 10t

have you thought about refurbing big grabs? I’d love to see them lose some work.

rory1

Member

- Messages

- 1,200

- Location

- Macclesfield

Would you have any insight into why some borers are right hand headstock like your own (and the one Brian Block has) and others are left hand headstock (like El metal Raymond and the one Abom used to use)? Thanks.

no idea I’m afraid, my pals got a kearns S type and it’s the other hand to my SH 75

My Old Landy

Engineering Mayhem

- Messages

- 3,498

- Location

- North Lincs

He does YouTube full time so I suppose you have to look past that at the technique etc.I gave up on that Abom guy, it appeared he was always looking for something free or on the cheap, tools etc.

I just watch the interesting ones and leave the rest

mtt.tr

Member

- Messages

- 8,465

- Location

- Essex/Suffolk border

me and that borer have a Turbulent relationship. I love it but it hates me and insists that I keep spending money on it.

You shouldn't have married it

Dcal

Member

- Messages

- 4,094

- Location

- Antrim Northern Ireland

I'm working on and off on an old Dexta tractor.

The timing cover is aluminium and the rest of the engine is cast iron including the water pump that bolts to the timing cover.

It hasn’t seen antifreeze or inhibitor in 50 years at a guess and there is corrosion to the alloy behind the water pump probably as a result of galvanic corrosion.

Anyway instead of trying to get a new cover or filling the pits with quick metal I decided to try and weld it.

I have about one hour arc time on alloy and know even less about machining, so don't expect much.

Cleanned it as best I could for tig welding with a burr.

And first welds.

It boilled out a lot of crap and the only 40 series rod I have is 0.8mm mig wire so I wound some together and cracked on.

It started to distort the cover so I ground most of the weld out and fitted it back onto the engine and then welded it again.

It went better this time, but I did have to grind out a few deep holes that appeared and fill them back up again.

I don't have a mill but I do have a shaper.

I also don't have a clue how to do these things, so to hold it in place on the shaper I welded and drilled a bit of flat bar and used the threaded holes for mounting the water pump to fix it to the back of the timing cover.

There is only 3 tapped holes, the forth is a through hole into the engine timing casing so didn't bother with it.

I now have something to grip in the vise on the shaper.

Clamped it in the vise in the shaper and had a go.

Set up was very approximate and I had to take more off that I would have liked but I'm quite pleased with how it turned out.

You can see the weld metal but it seems to be well stuck in there and it's straight and flat as far as I can tell.

I could have had another go filling the blow holes and the like but enoughs enough.

Don't know of it will work but it's no worse than it was.

The timing cover is aluminium and the rest of the engine is cast iron including the water pump that bolts to the timing cover.

It hasn’t seen antifreeze or inhibitor in 50 years at a guess and there is corrosion to the alloy behind the water pump probably as a result of galvanic corrosion.

Anyway instead of trying to get a new cover or filling the pits with quick metal I decided to try and weld it.

I have about one hour arc time on alloy and know even less about machining, so don't expect much.

Cleanned it as best I could for tig welding with a burr.

And first welds.

It boilled out a lot of crap and the only 40 series rod I have is 0.8mm mig wire so I wound some together and cracked on.

It started to distort the cover so I ground most of the weld out and fitted it back onto the engine and then welded it again.

It went better this time, but I did have to grind out a few deep holes that appeared and fill them back up again.

I don't have a mill but I do have a shaper.

I also don't have a clue how to do these things, so to hold it in place on the shaper I welded and drilled a bit of flat bar and used the threaded holes for mounting the water pump to fix it to the back of the timing cover.

There is only 3 tapped holes, the forth is a through hole into the engine timing casing so didn't bother with it.

I now have something to grip in the vise on the shaper.

Clamped it in the vise in the shaper and had a go.

Set up was very approximate and I had to take more off that I would have liked but I'm quite pleased with how it turned out.

You can see the weld metal but it seems to be well stuck in there and it's straight and flat as far as I can tell.

I could have had another go filling the blow holes and the like but enoughs enough.

Don't know of it will work but it's no worse than it was.

mtt.tr

Member

- Messages

- 8,465

- Location

- Essex/Suffolk border

Watched this earlier. I need to get a cheap laser, looks like it would work well. Anyone tried it? (2:15)

Hes very very clever that guy