You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A few random stainless jobs

- Thread starter Paul.

- Start date

Paul.

Moderator

- Messages

- 7,052

- Location

- Northampton. UK

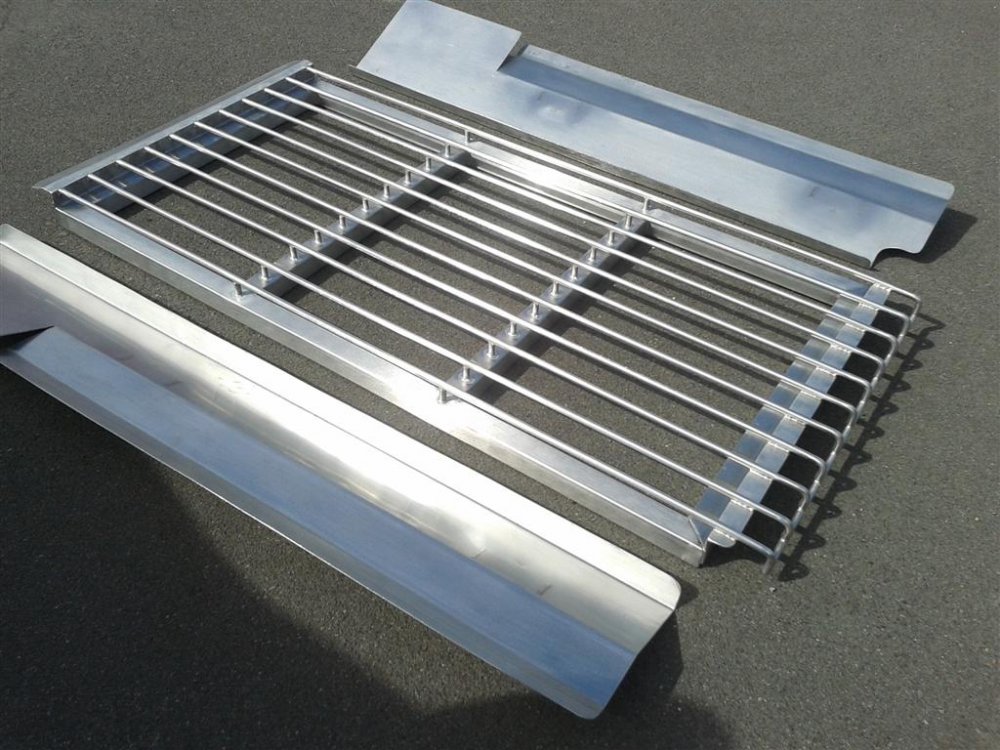

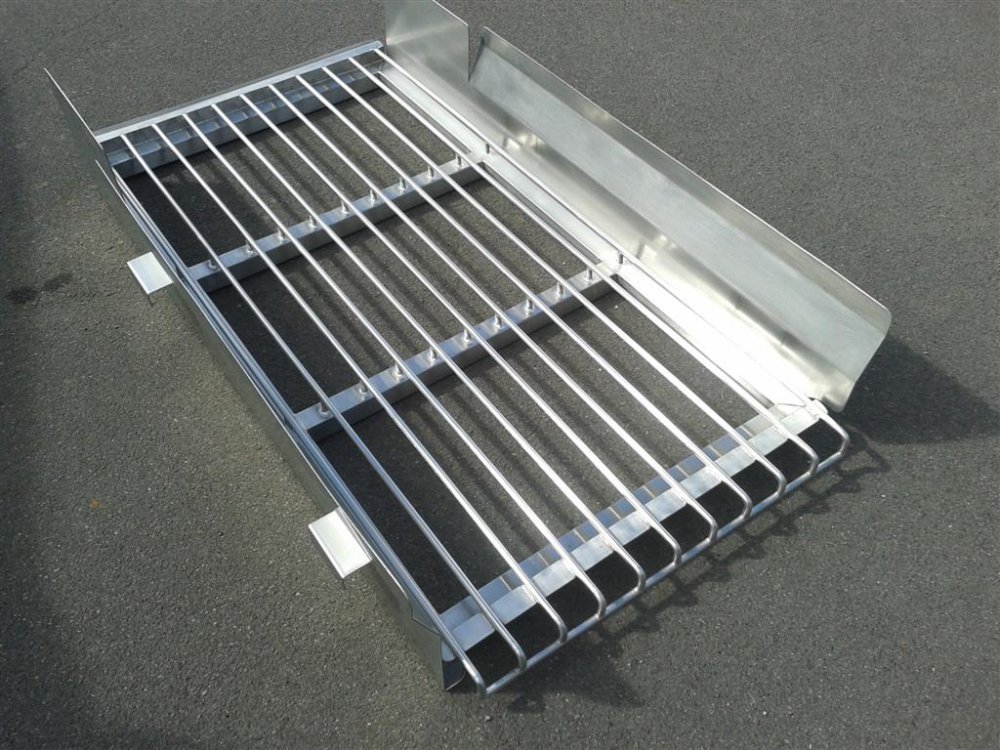

Another stainless part, this is a slide to get meat out of an injection machine into a dolav,

Its actually an alternative to the outfeed roller bed in this job, "clickme" to deal with a different meat product that doesn't travel over the rollers too well.

A proper wrist twister welding it up, every joint is continuously welded for hygiene purposes

Some sheet metal sides to go with it

Its actually an alternative to the outfeed roller bed in this job, "clickme" to deal with a different meat product that doesn't travel over the rollers too well.

A proper wrist twister welding it up, every joint is continuously welded for hygiene purposes

Some sheet metal sides to go with it

eSCHEn

Bit Wrangler

- Messages

- 6,136

- Location

- SW Scotland

That looks a bit of a swine to weld up Paul. Very neat work mateAnother stainless part, this is a slide to get meat out of an injection machine into a dolav,

Its actually an alternative to the outfeed roller bed in this job, "clickme" to deal with a different meat product that doesn't travel over the rollers too well.

A proper wrist twister welding it up, every joint is continuously welded for hygiene purposes

View attachment 66850

Some sheet metal sides to go with it

View attachment 66851 View attachment 66849

gordon stephenson

Member

- Messages

- 7,464

- Location

- Skelton in Cleveland U.K.

Hi Paul, excellent as always., you just continue to make the rest of us bad,

Mid Wales welder

Welder coding and NDT services

- Messages

- 672

- Location

- Powys, U.K.

Little job finished off today, its a trolley to make a platform scale mobile, material is 100 x 50 3 and 50 x 50 x 3 box section, the scale is 130 deep and needs to be level with the top of the frame so there is a 30mm box section fame underneath to get the depth,

View attachment 65784

The scale has rubber feet so some simple location brackets will keep it in place

View attachment 65785

The scale fitted, without and then with the stainless platform on.

View attachment 65786 View attachment 65787

The handle is fabricated from 1" stainless tube and pre formed bends then its all polished out, there are five separate pieces to it, can you spot the joins.

View attachment 65788

A swivel bracket for the head completes the job, a couple of polyethylene plates drilled to be a tight fit on the tube keep it together and provide a bearing surface

View attachment 65789

Amazing work! Can I ask how you polish up your stainless like that?

Paul.

Moderator

- Messages

- 7,052

- Location

- Northampton. UK

Elbow grease and patience, coupled with a combination of pickling paste, scotchbrite, wire brushes, flap wheels, and garryson blocks, for sheet metal you can get a nice clean industrial finish with a DA sander and scotchbrite,Amazing work! Can I ask how you polish up your stainless like that?

This motor guard was made from 2B sheet, and hand finished with scotchbrite and abrasive block,

Its to replace this one that Mr maintenance has had a go at repairing.

Mid Wales welder

Welder coding and NDT services

- Messages

- 672

- Location

- Powys, U.K.

Elbow grease and patience, coupled with a combination of pickling paste, scotchbrite, wire brushes, flap wheels, and garryson blocks, for sheet metal you can get a nice clean industrial finish with a DA sander and scotchbrite,

This motor guard was made from 2B sheet, and hand finished with scotchbrite and abrasive block,

View attachment 67210

Its to replace this one that Mr maintenance has had a go at repairing.

View attachment 67209

How long did it take you to clean that up? I had to make some stainless conveyors (weren't for food, just used for moving pallets of grit salt) out of 4mm 304, they had been folded on the press brake and were a bit scratched and the tool marks were quite deep. I went over them with an 80 grit flap disk to get the whole thing looking the same, (they were 2.5m long) just walking along with the same pressure with out stopping end to end, then repeated with a 180 gripe flap disk and then the same with a soft polishing flap wheel. That took long enough to do! The customer was happy with how it turned out but I think next time I will finish off with scotch bright too.

Do you use any type of polishing wax (can't think of right name lol)? Or is it just a dry scotchbright?

This is the only picture I have, but you can see where it's been polished.

That's just a small bracket welded on for a switch to go into before being cleaned.

Paul.

Moderator

- Messages

- 7,052

- Location

- Northampton. UK

You would be better off not getting the tooling marks in the first place, urethane film on the vee will stop a lot if not all of the marks and soon pays for itself when factored against the time involved cleaning up, even a line of masking tape or gaffer tape on the bend can save you hours, make sure the tooling is clean and free from marks before you start,

Flap discs not really ideal for surfacing large areas, you just end up with a lot of swirly scratches, and a job that looks like its made from mild steel and is ready for painting,

flap WHEELS, can be used in line with the bend to put in or reinstate a grained finish,

You can use scotchbrite dry, but a bit of soapy water will make a big difference to how it works when used for graining by hand,

Also don't forget media blasting can give a really nice finish especially for food machinery,

Glass bead transformed this,

into this

Flap discs not really ideal for surfacing large areas, you just end up with a lot of swirly scratches, and a job that looks like its made from mild steel and is ready for painting,

flap WHEELS, can be used in line with the bend to put in or reinstate a grained finish,

You can use scotchbrite dry, but a bit of soapy water will make a big difference to how it works when used for graining by hand,

Also don't forget media blasting can give a really nice finish especially for food machinery,

Glass bead transformed this,

into this

brightspark

Member

- Messages

- 40,420

- Location

- yarm stockton on tees

nice jobYou would be better off not getting the tooling marks in the first place, urethane film on the vee will stop a lot if not all of the marks and soon pays for itself when factored against the time involved cleaning up, even a line of masking tape or gaffer tape on the bend can save you hours, make sure the tooling is clean and free from marks before you start,

Flap discs not really ideal for surfacing large areas, you just end up with a lot of swirly scratches, and a job that looks like its made from mild steel and is ready for painting,

flap WHEELS, can be used in line with the bend to put in or reinstate a grained finish,

You can use scotchbrite dry, but a bit of soapy water will make a big difference to how it works when used for graining by hand,

Also don't forget media blasting can give a really nice finish especially for food machinery,

Glass bead transformed this,

View attachment 67273

into this

View attachment 67272

Mid Wales welder

Welder coding and NDT services

- Messages

- 672

- Location

- Powys, U.K.

You would be better off not getting the tooling marks in the first place, urethane film on the vee will stop a lot if not all of the marks and soon pays for itself when factored against the time involved cleaning up, even a line of masking tape or gaffer tape on the bend can save you hours, make sure the tooling is clean and free from marks before you start,

Flap discs not really ideal for surfacing large areas, you just end up with a lot of swirly scratches, and a job that looks like its made from mild steel and is ready for painting,

flap WHEELS, can be used in line with the bend to put in or reinstate a grained finish,

You can use scotchbrite dry, but a bit of soapy water will make a big difference to how it works when used for graining by hand,

Also don't forget media blasting can give a really nice finish especially for food machinery,

Glass bead transformed this,

View attachment 67273

into this

View attachment 67272

Ah that's a good idea about the urethane film! I don't do the press work, that's another guy, but I will suggest that to the boss next time. We don't really do a lot of stainless work (at least not where it needs to look that tidy) so the boss won't get the glass bead, but it may be worth changing the Ali shot to glass if we get a lot of stuff to do. We've had some stuff in to repair that was glass bead blasted and it looks really nice.

Did you pickle those welds before having them blasted?

DAPPH

as dyslexik as I'm daft

- Messages

- 7,234

- Location

- Near to Cross Hands Llanelli SouthWales GB

I used to hold a torch for a girl local to me.

You had a fire but no flame ?

Paul.

Moderator

- Messages

- 7,052

- Location

- Northampton. UK

Well the outfeed slide in post 23 above is working very well, so much so that I've now been asked to provide a slide for the feed side of the machine, much the same as before, pictures are before cleaning and an hour or so later when the pickling paste and a bit of elbow grease has done its job.

Before

After

Then got caught with one of those jobs that you have to do for next to nothing.

Some brackets to hang pushbikes from a garage roof rafters

Before

After

Then got caught with one of those jobs that you have to do for next to nothing.

Some brackets to hang pushbikes from a garage roof rafters

Paul.

Moderator

- Messages

- 7,052

- Location

- Northampton. UK

The latest creation, stainless steel fencing to go round some garden decking, there is no fall risk, its just a fence to make a play area, the gaps will be filled in with 10mm glass edged acrylic panels,

At the far end on the short leg there is a pair of gates, this is just the RH one with the post, still have the bolt and latch to do here, the hinge pivot bolt has a sleeve over it so that the threads are not worn away

It will be tied into an existing fence at each end, so I've stuck a rivet nut in to fix a bracket to

At the far end on the short leg there is a pair of gates, this is just the RH one with the post, still have the bolt and latch to do here, the hinge pivot bolt has a sleeve over it so that the threads are not worn away

It will be tied into an existing fence at each end, so I've stuck a rivet nut in to fix a bracket to

gordon stephenson

Member

- Messages

- 7,464

- Location

- Skelton in Cleveland U.K.

Top class Paul, very impressive as per normal for you,

Paul.

Moderator

- Messages

- 7,052

- Location

- Northampton. UK

Cheers chaps, its simple stuff really though, here is a lower angle showing how the posts are attached, there are two rivetnuts at each joint, then assembled with button head socket screws, there are also drain holes at the foot of each post and under the top rail, I've seen these bolt together structures bulge on the flat sides when they have had frozen water in them. the mounting holes in the acrylic panels will be slotted to allow for expansion and contraction, the customer is a plastics specialist so I'll leave that to him.

gordon stephenson

Member

- Messages

- 7,464

- Location

- Skelton in Cleveland U.K.

Thanks for the details Paul, Its the little things gained through much experience that gives the edge to top class work and elevates it above the usual run of the mill fabrications.