Minor progress report. Been pottering a bit in the garage over the weekend and then concentrated a bit more this evening.

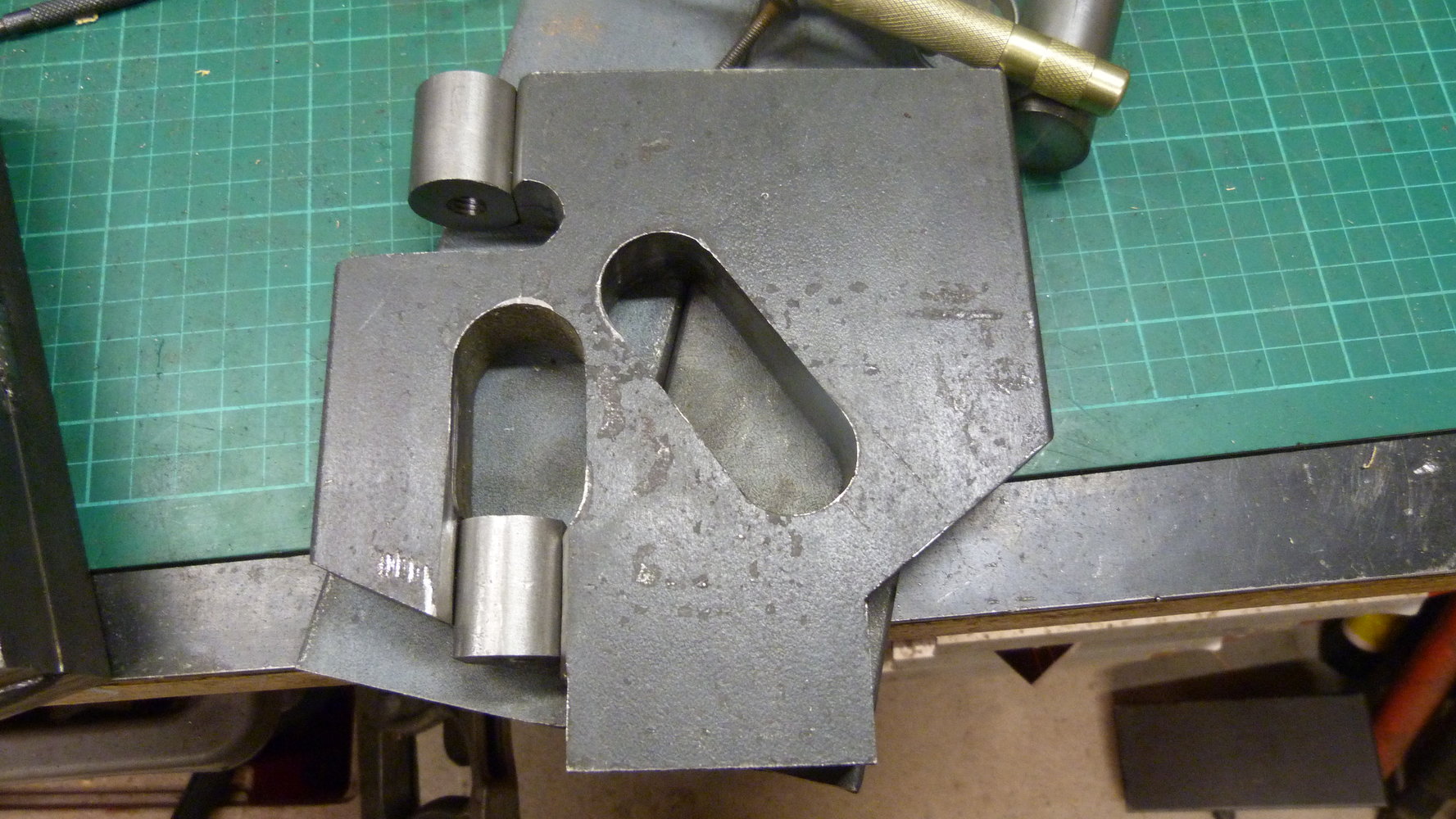

Firstly, the original 12mm frames I messed up. Thought it was a shame to waste all that time and effort spent milling. I decided to treat them as one frame welded together and maybe make another later on to match. I chopped out the drilling mistakes and then centre drilled, tapped m10 and milled some 25mm round bar to fit. Needs welding together at another time.

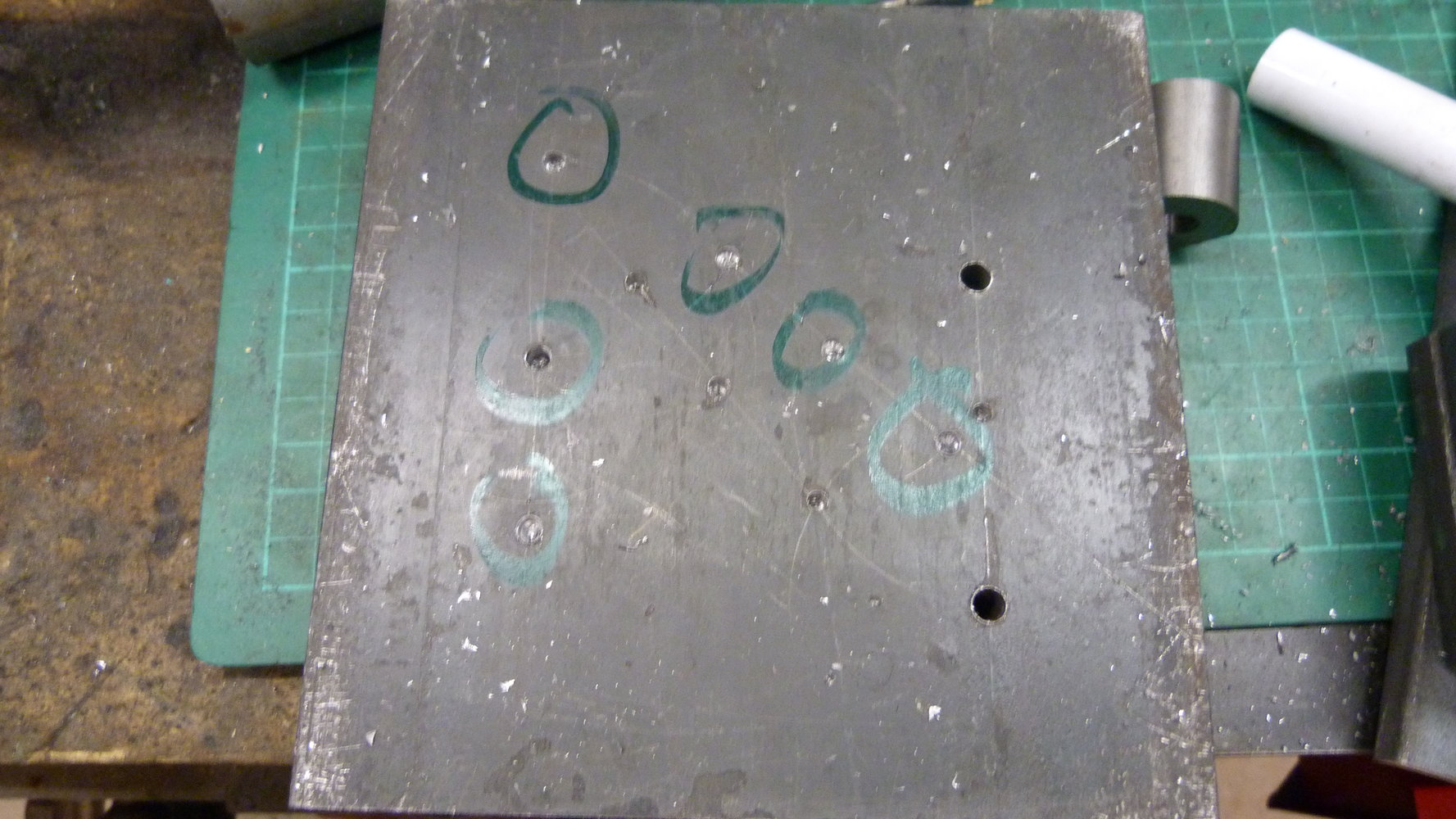

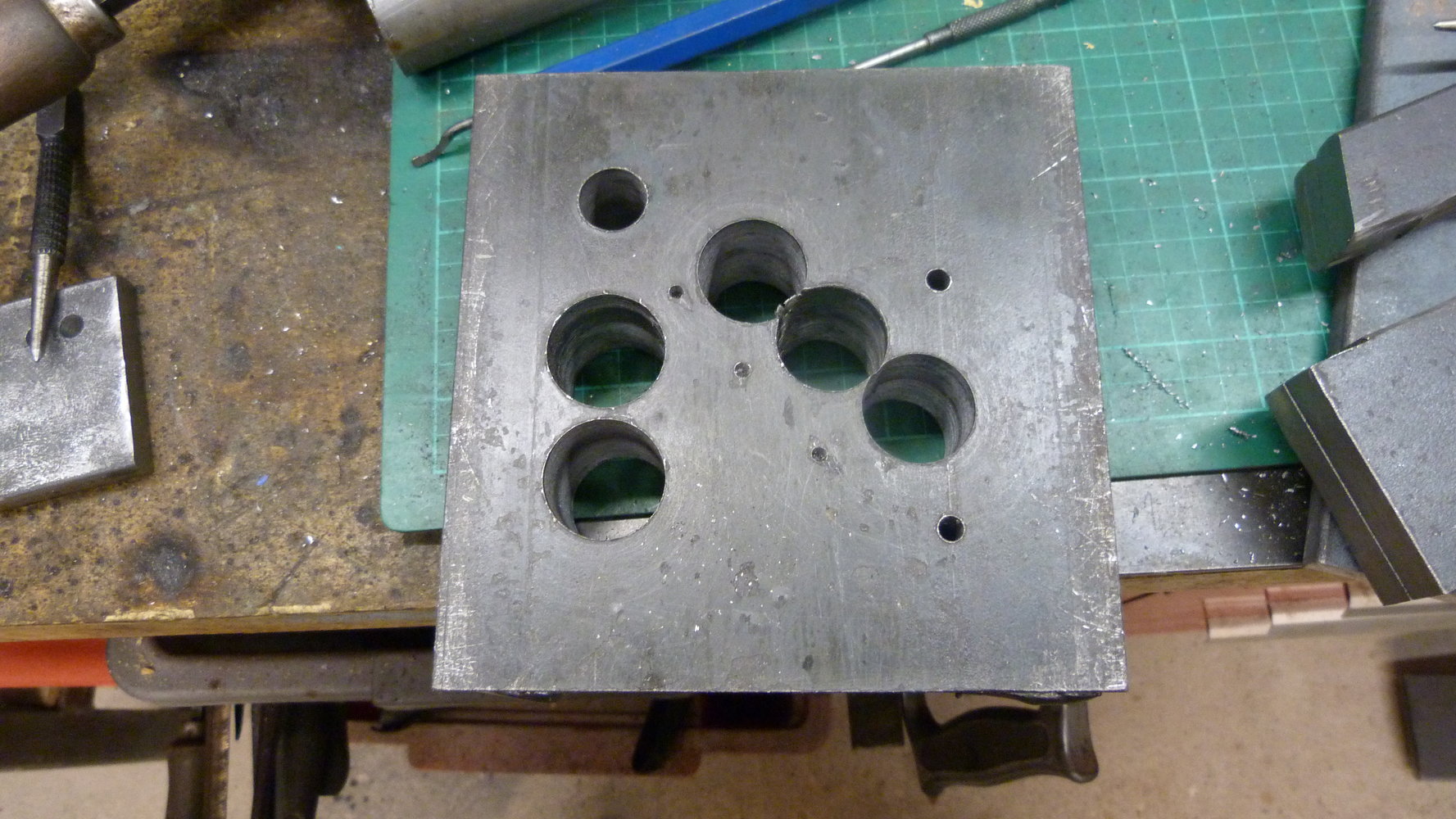

Onto the two 20mm plates for the inch and a half cds tube. Ignore the two holes on the right hand side. That was a mistake from last week using 34mm centres that I'm no longer using and due to the work not being held flat in the drill vice, the top drilled hole went in at an angle so the holes would be at differing heights.

I've learned from last time and put the top hole and the vertical slot 5mm closer to the left hand edge. I have also flattened the angled slot by 5 degrees.

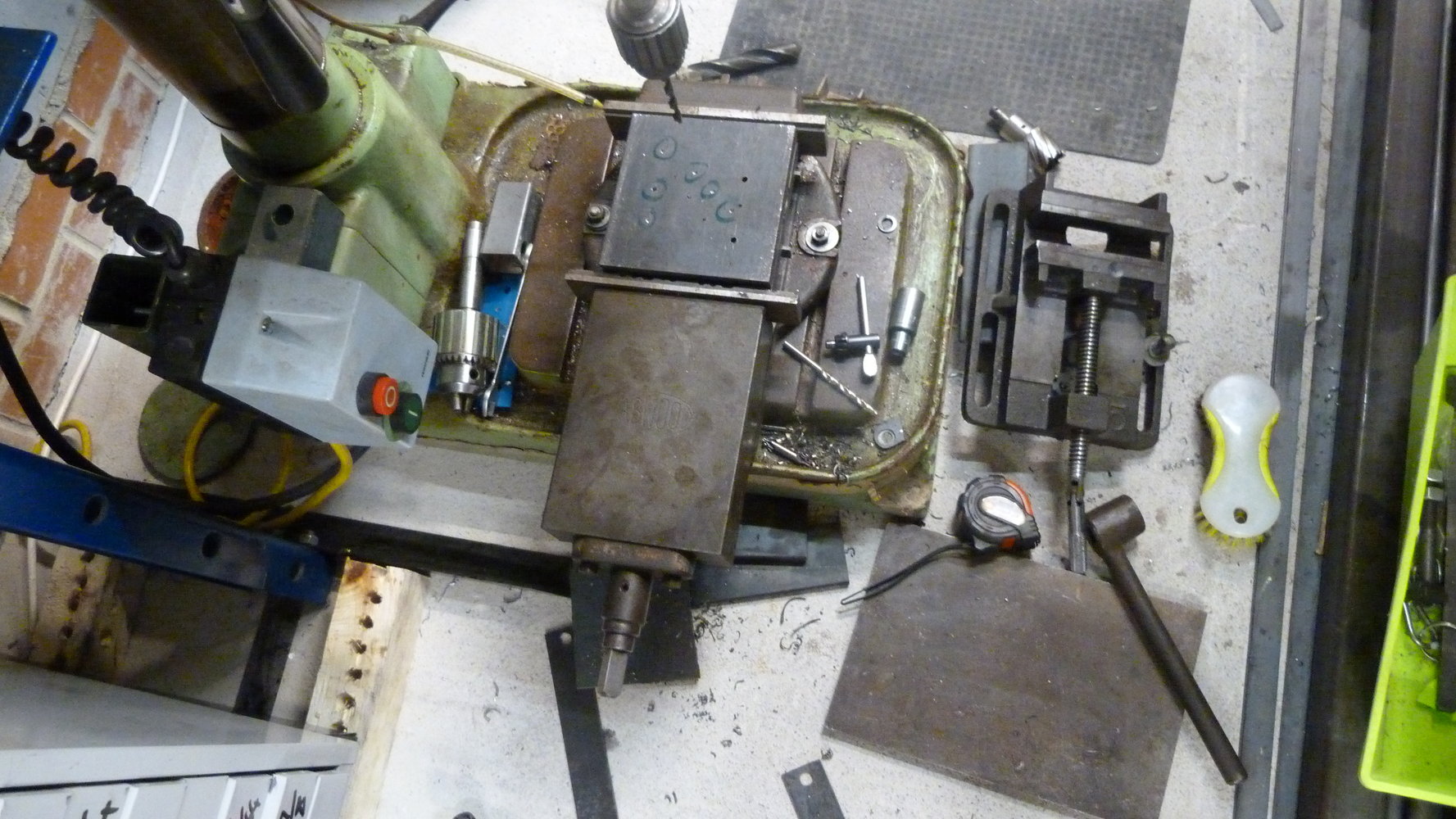

I've got the big 6" Abwoood milling vice out. It is a pain the rear end to set up work accurately for drilling. I have to move the work in the jaws to set the y axis and slide the bolts/vice in the T slots to adjust my x axis.

The good thing about it is it will hold the work in the jaws fully so I don't have to weld a tab to the work and clamp off that. This keeps the work flat so no drills going in at silly angles. The vice is much sturdier and holds the work better. I have parallels under the workpiece. I used a spirit level to make sure the work was flat (This time).

Look how clean the drill table was before I started.

Spirit level. (Used on the work piece to check it is flat. It is doing nothing sat on the milling vice here.)

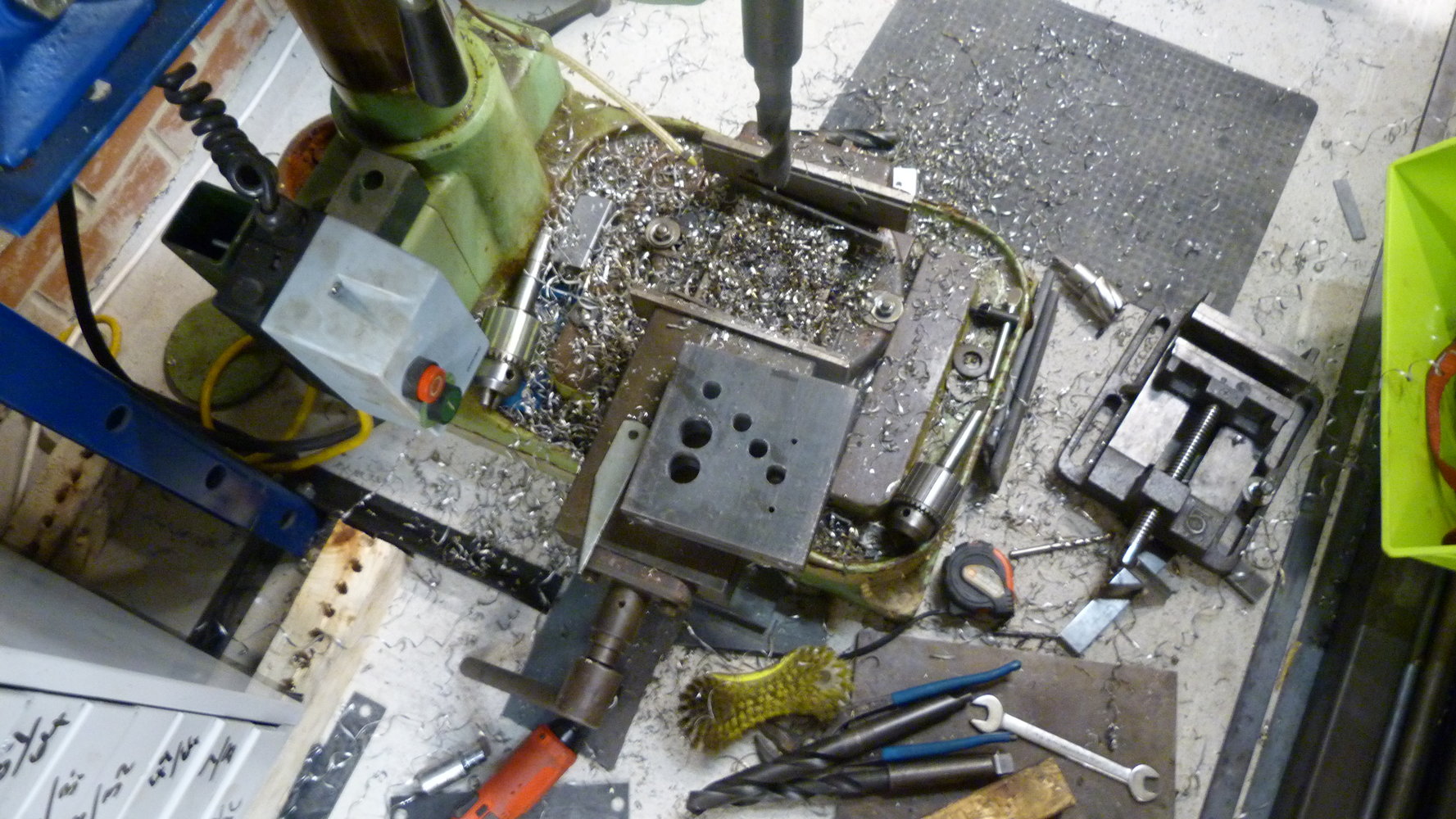

I picked the wrong drill up and those two big holes are 1 and 1/16" rather than 1" but this doesn't matter.

Just about done.

Ready for milling, cutting shaping etc. 16mm hole top left. Angled slot holes are 1". Vertical slot holes are 1 and1/16". The plates are 40mm thick in total. I had to wear gloves to pick this out of the vice when finished due to the heat. I don't know what went wrong with the vertical slot. I thought I had set my drill holes an inch apart but there's still a fair old gap to remove.

This was a lot of work and discomfort when working on the floor.

Tomorrow evening I shall be mostly sweeping up.

Firstly, the original 12mm frames I messed up. Thought it was a shame to waste all that time and effort spent milling. I decided to treat them as one frame welded together and maybe make another later on to match. I chopped out the drilling mistakes and then centre drilled, tapped m10 and milled some 25mm round bar to fit. Needs welding together at another time.

Onto the two 20mm plates for the inch and a half cds tube. Ignore the two holes on the right hand side. That was a mistake from last week using 34mm centres that I'm no longer using and due to the work not being held flat in the drill vice, the top drilled hole went in at an angle so the holes would be at differing heights.

I've learned from last time and put the top hole and the vertical slot 5mm closer to the left hand edge. I have also flattened the angled slot by 5 degrees.

I've got the big 6" Abwoood milling vice out. It is a pain the rear end to set up work accurately for drilling. I have to move the work in the jaws to set the y axis and slide the bolts/vice in the T slots to adjust my x axis.

The good thing about it is it will hold the work in the jaws fully so I don't have to weld a tab to the work and clamp off that. This keeps the work flat so no drills going in at silly angles. The vice is much sturdier and holds the work better. I have parallels under the workpiece. I used a spirit level to make sure the work was flat (This time).

Look how clean the drill table was before I started.

Spirit level. (Used on the work piece to check it is flat. It is doing nothing sat on the milling vice here.)

I picked the wrong drill up and those two big holes are 1 and 1/16" rather than 1" but this doesn't matter.

Just about done.

Ready for milling, cutting shaping etc. 16mm hole top left. Angled slot holes are 1". Vertical slot holes are 1 and1/16". The plates are 40mm thick in total. I had to wear gloves to pick this out of the vice when finished due to the heat. I don't know what went wrong with the vertical slot. I thought I had set my drill holes an inch apart but there's still a fair old gap to remove.

This was a lot of work and discomfort when working on the floor.

Tomorrow evening I shall be mostly sweeping up.

Last edited: