Nearly getting there. I have been procrastinating distracted with other stuff in the garage, as you do. I think I was also getting bit apprehensive about reaching the end and finding it doesn't work.

On Sunday I finally got round to welding the feet to the frames. I had a little go welding on some scrap before diving in but I am well out of practice with stick welding. This was the best weld of a bad bunch. I am a bit disappointed with them but at least everything came out square so I am thankful for that. 3.2mm 6013 rod125 amps again.

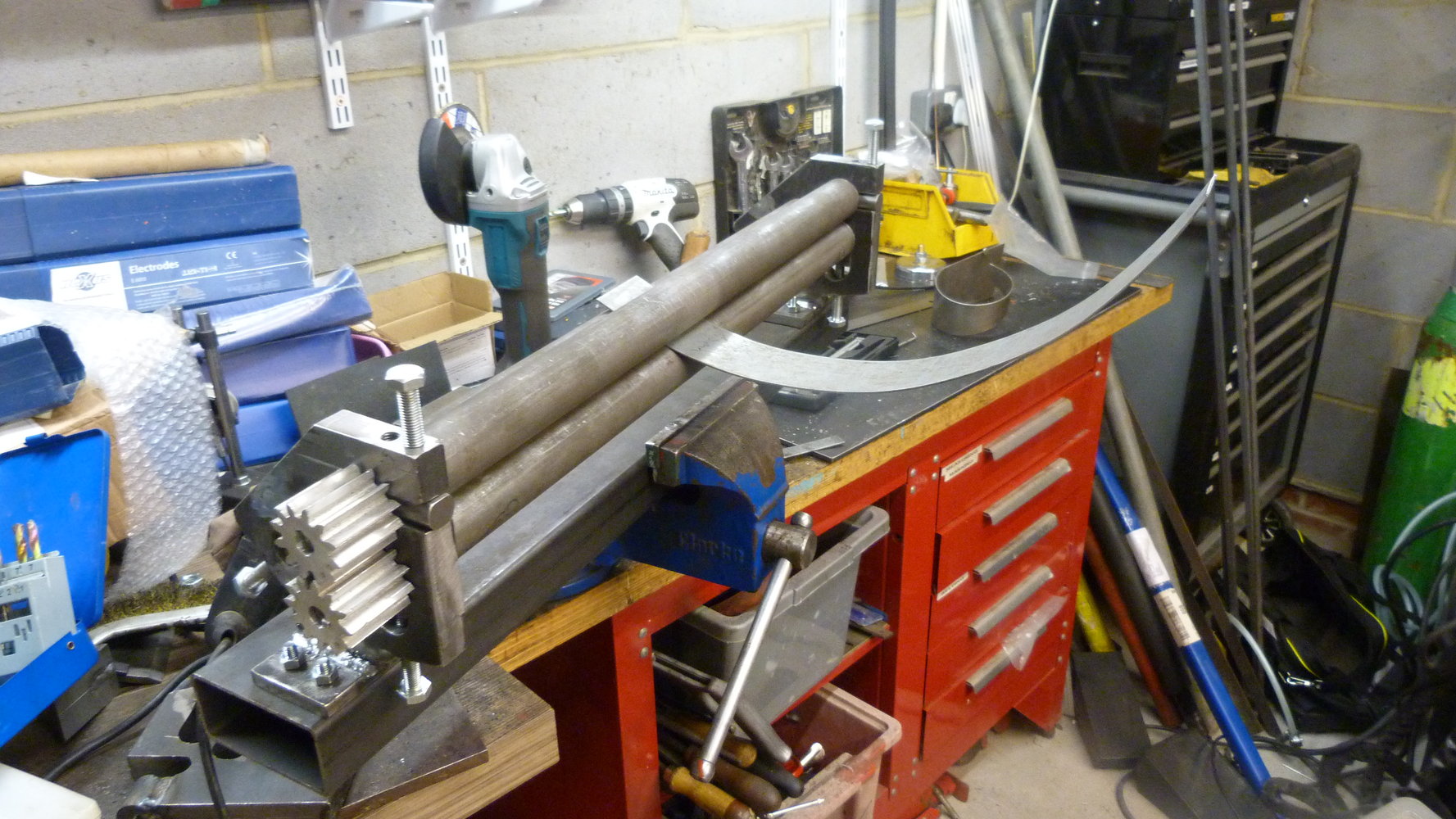

After that I had no excuse for not setting the thing up. I marked up and drilled mounting holes in the box section freehand. The box section got shortened a bit as I had to get the bolts pushed up from the inside the box section so the closer to the open ends for the holes the better. The tool is very front heavy and a little unbalanced. I wish I hadn't cut the back corners off the plates now.

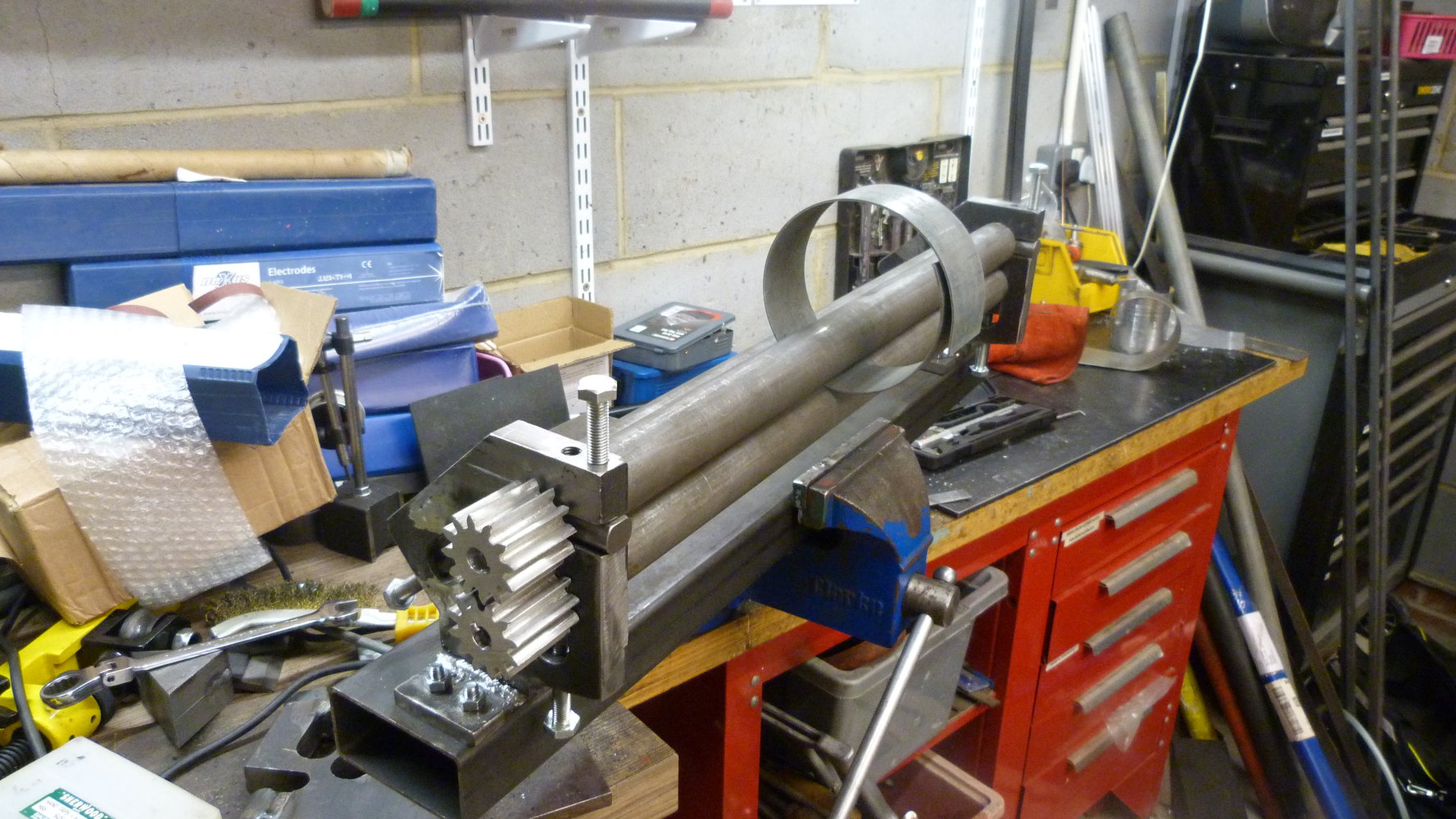

First ever go with the machine. This is "waffer thin" aluminium. Very much sub one mm. Yay! I've sort of made a thing from scratch that works!!

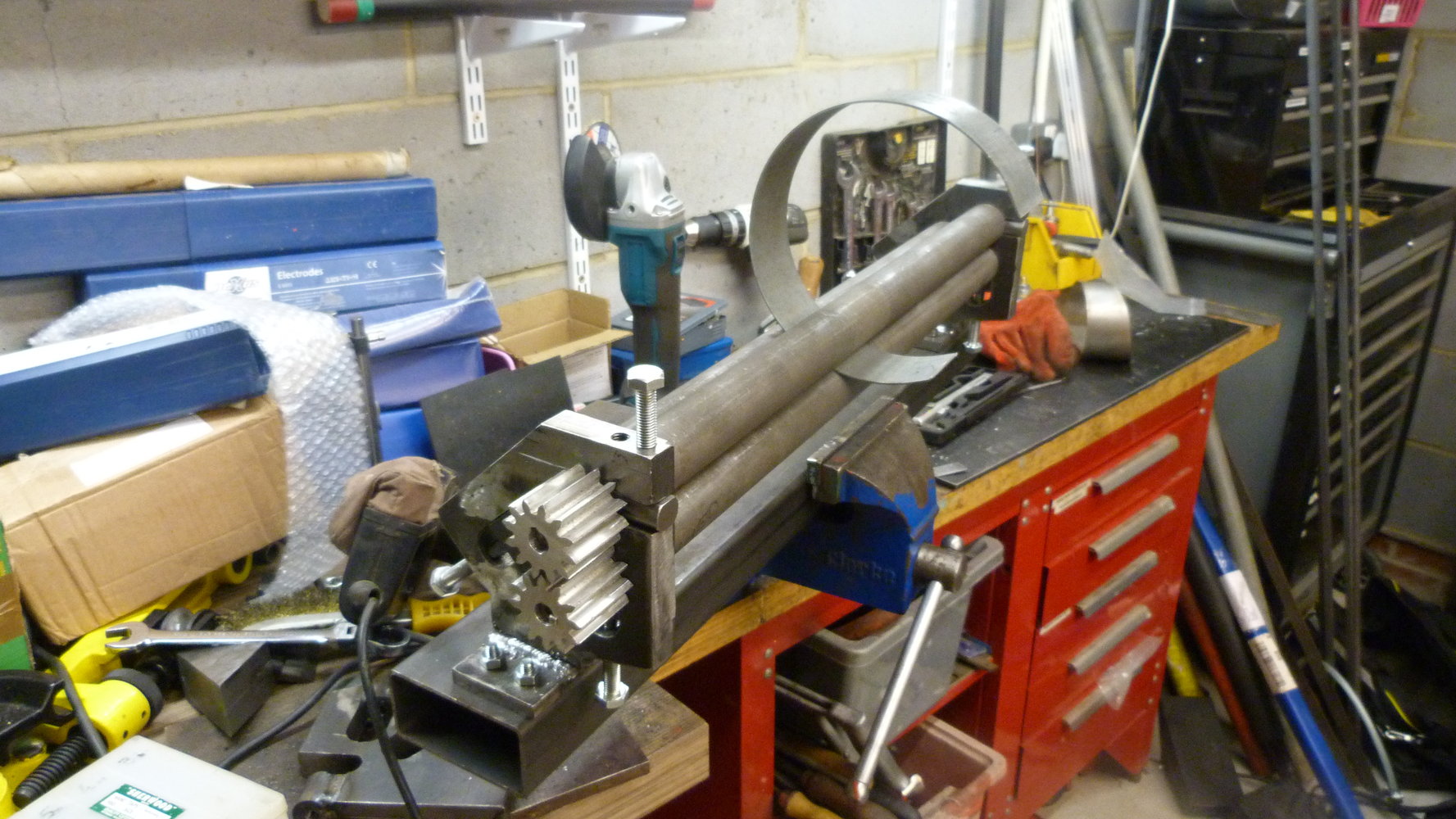

There's loads of little things still to sort on the machine. I don't even have a handle made for it yet so I put the spare spur gear on the spare keyed shaft and used it to turn the rollers with a gloved hand. It gave a decent, if uncomfortable, grip.

This is 1.5mm steel, 55mm wide. I'm just testing offcuts and scraps tonight. Not a very good test of a 600 mm wide machine but baby steps.

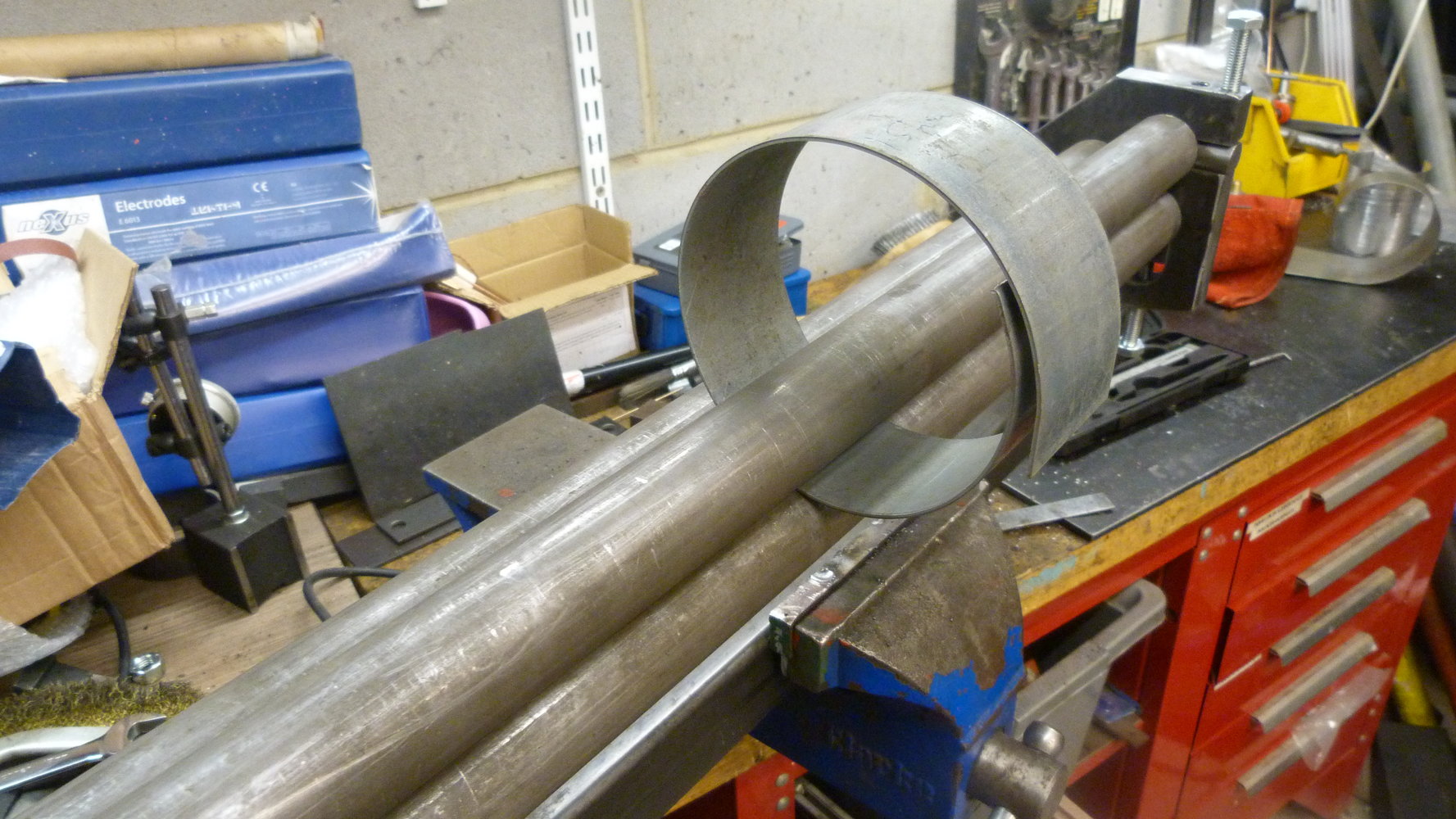

I'm quite pleased that the material rolled with hardly any evident spiral . The overlapping edges showed hardly any twist.

Left to right below, 1.5mm steel, 1.2mm steel 0.8mm aluminum. The middle piece isn't twisted, it just has a massive taper on it. Like a very long wedge. It's just a funny shaped offcut that was too big to throw out.

I hope that by using a handle the machine will give smoother curves. I was turning the rollers by hand using the spare gear. Consequently, it wasn't a very smooth and steady rolling operation but instead very stop start.

It was only a quick go with it tonight but I was pleasantly surprised how well it worked so far. The general design and inherent adjustabilty seems pretty tolerant of my shoddy machining. I'm looking forward to making a handle now and having a proper go with the machine.

I have a slight nagging feeling that the rear roller slot that sets the curve should have been set further back and a bit higher up for really tight rolls. Too late now of course. I will have to find out what the minimum roll diameter is that I can make with the machine.

On Sunday I finally got round to welding the feet to the frames. I had a little go welding on some scrap before diving in but I am well out of practice with stick welding. This was the best weld of a bad bunch. I am a bit disappointed with them but at least everything came out square so I am thankful for that. 3.2mm 6013 rod125 amps again.

After that I had no excuse for not setting the thing up. I marked up and drilled mounting holes in the box section freehand. The box section got shortened a bit as I had to get the bolts pushed up from the inside the box section so the closer to the open ends for the holes the better. The tool is very front heavy and a little unbalanced. I wish I hadn't cut the back corners off the plates now.

First ever go with the machine. This is "waffer thin" aluminium. Very much sub one mm. Yay! I've sort of made a thing from scratch that works!!

There's loads of little things still to sort on the machine. I don't even have a handle made for it yet so I put the spare spur gear on the spare keyed shaft and used it to turn the rollers with a gloved hand. It gave a decent, if uncomfortable, grip.

This is 1.5mm steel, 55mm wide. I'm just testing offcuts and scraps tonight. Not a very good test of a 600 mm wide machine but baby steps.

I'm quite pleased that the material rolled with hardly any evident spiral . The overlapping edges showed hardly any twist.

Left to right below, 1.5mm steel, 1.2mm steel 0.8mm aluminum. The middle piece isn't twisted, it just has a massive taper on it. Like a very long wedge. It's just a funny shaped offcut that was too big to throw out.

I hope that by using a handle the machine will give smoother curves. I was turning the rollers by hand using the spare gear. Consequently, it wasn't a very smooth and steady rolling operation but instead very stop start.

It was only a quick go with it tonight but I was pleasantly surprised how well it worked so far. The general design and inherent adjustabilty seems pretty tolerant of my shoddy machining. I'm looking forward to making a handle now and having a proper go with the machine.

I have a slight nagging feeling that the rear roller slot that sets the curve should have been set further back and a bit higher up for really tight rolls. Too late now of course. I will have to find out what the minimum roll diameter is that I can make with the machine.

). A pair of feet have been welded to the front to prevent this. This is my replacement handle. The keyed centre has a taper front to back just to complicate things a bit.

). A pair of feet have been welded to the front to prevent this. This is my replacement handle. The keyed centre has a taper front to back just to complicate things a bit.