You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

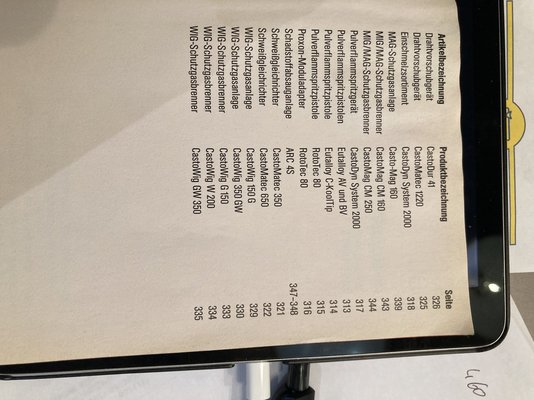

Castolin RotoTec & Eutalloy Powder Spraying Systems

- Thread starter Brad93

- Start date

Jim Davey

R H Davey Welding Supplies Ltd

- Messages

- 5,734

- Location

- Southampton

The Eutalloy torch does have different nozzles available. I’ve got a couple of clients that use them for adding a hard stainless coating to the leading edges of stainless mixing paddles for the pharmaceutical industry.

Got some larger eutectic and Stubbs powder spray systems in with motor rewind firms for cladding and shaft repair on motors and pumps etc.

Can be used to great effect for cast iron crack repairs too but a lot of the knowledge/experience is lost out there now and the kits fall into disrepair and then stop getting used altogether.

Got some larger eutectic and Stubbs powder spray systems in with motor rewind firms for cladding and shaft repair on motors and pumps etc.

Can be used to great effect for cast iron crack repairs too but a lot of the knowledge/experience is lost out there now and the kits fall into disrepair and then stop getting used altogether.

Brad93

Member

- Messages

- 18,564

- Location

- Essex, United Kingdom

Not just on the shop floor, but at Castolin themselves I fear. I've not really had much joy with sales department regarding the spray welding stuff.The Eutalloy torch does have different nozzles available. I’ve got a couple of clients that use them for adding a hard stainless coating to the leading edges of stainless mixing paddles for the pharmaceutical industry.

Got some larger eutectic and Stubbs powder spray systems in with motor rewind firms for cladding and shaft repair on motors and pumps etc.

Can be used to great effect for cast iron crack repairs too but a lot of the knowledge/experience is lost out there now and the kits fall into disrepair and then stop getting used altogether.

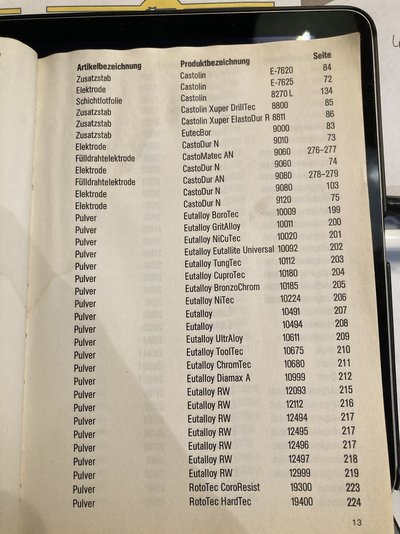

I did buy a new pot of 10224 Nitec for cast iron. I've not had a chance to play yet.

Brad93

Member

- Messages

- 18,564

- Location

- Essex, United Kingdom

Powder is a better price from them but designed for their systems. Larger quantities too so not much difference in buying from Castolin unless your a large scale userAny experience with Oerlikon Metco for powder?

Jan-DIY

Member

- Messages

- 809

- Location

- Lower Saxony Germany

Ok. Thanks for that.

Got a whole bunch of that stuff arranged in my place just for playing around.

Also had a nice chat with Ibeda to get a quote for new nozzles for my flame jet.

They are really competent on these stuff.

But as usual.

Special industrial tools are on special prices.

Got a whole bunch of that stuff arranged in my place just for playing around.

Also had a nice chat with Ibeda to get a quote for new nozzles for my flame jet.

They are really competent on these stuff.

But as usual.

Special industrial tools are on special prices.

Rrunnach

Member

- Messages

- 1,127

- Location

- Scotland

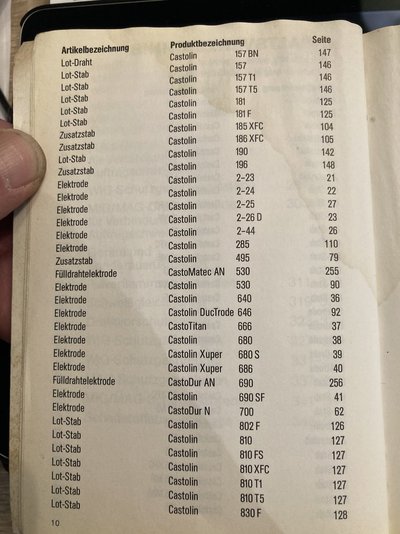

Man, when I see the Eutectic+Castolene brand name, and the posted handbooks with their Feltham Middlesex HQ address, brings back fond memories of my second job interview with them. A quick google shows they have switched brand name around, and no longer in Middlesex.

Their 316L MMA rods were famous to find a bit of bare skin when the flux pinged off!!

Their 316L MMA rods were famous to find a bit of bare skin when the flux pinged off!!

Jim Davey

R H Davey Welding Supplies Ltd

- Messages

- 5,734

- Location

- Southampton

Man, when I see the Eutectic+Castolene brand name, and the posted handbooks with their Feltham Middlesex HQ address, brings back fond memories of my second job interview with them. A quick google shows they have switched brand name around, and no longer in Middlesex.

Their 316L MMA rods were famous to find a bit of bare skin when the flux pinged off!!

They are based in Redditch these days.

Rrunnach

Member

- Messages

- 1,127

- Location

- Scotland

Hi, yes I saw this, during my interview, I'll never forget my focus on the Heathrow aircraft taking off, instead of full focus on interview, certainly good memories!!They are based in Redditch these days.

Interesting stuff. Are you using this for paid repair jobs Brad, or saving it for your own last resort jobs? Just in case something comes along that needs it....

My only experience of this was from pump motor shafts we used to get built up where the seal or bearing had taken the shaft down. The job never lasted - it seemed the metal was soo soft - were the rebuilders doing it wrong? This was on high speed/stress pumps in the evaporator. On larger, slow speed stuff we would build up with weld and machine.

My only experience of this was from pump motor shafts we used to get built up where the seal or bearing had taken the shaft down. The job never lasted - it seemed the metal was soo soft - were the rebuilders doing it wrong? This was on high speed/stress pumps in the evaporator. On larger, slow speed stuff we would build up with weld and machine.

Brad93

Member

- Messages

- 18,564

- Location

- Essex, United Kingdom

Done wrong probably.Interesting stuff. Are you using this for paid repair jobs Brad, or saving it for your own last resort jobs? Just in case something comes along that needs it....

My only experience of this was from pump motor shafts we used to get built up where the seal or bearing had taken the shaft down. The job never lasted - it seemed the metal was soo soft - were the rebuilders doing it wrong? This was on high speed/stress pumps in the evaporator. On larger, slow speed stuff we would build up with weld and machine.

I've done a few for local motor company, few for food industry (plastic bearing journal). No problems yet.

Im always happy to do them for people as long as they're willing to cover the powder.

I done a job for Clive. It used 68grams of powder. I think that was about £25 alone.

Thanks. We’ll see about the quill shaft on the Town Woodhouse, it has a fair bit of play in it, which might just need nipping the bearings up. But if the shaft is worn.....Done wrong probably.

I've done a few for local motor company, few for food industry (plastic bearing journal). No problems yet.

Im always happy to do them for people as long as they're willing to cover the powder.

I done a job for Clive. It used 68grams of powder. I think that was about £25 alone.