You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Citroen saxo rally/race build.

- Thread starter God mode restorations

- Start date

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Yes I will do something very similar.just do what burdekin said, drill the holes bigger then seam weld round them.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Been busy today making a fuel cell mounting box.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Nearly finished.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Well it's in the hole...not happy with it yet...

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Still got to make the supports for the box to sit on. Will include this when I replace the rear been crossmember ....

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

I had a challenge marking out the area where the box sits.so many different curves. The panel work is easily sorted.I could of got a smaller fuel cell but had what I had at that time.I wanted to keep it as low as possible. I new it would make contact with the crossmember. My plan is to use 45x60x4mm box section and fab a new one .I will mount it via spreader plates.I need to keep the original position of the axles mounting points.I will fab it around the bottom of the tank with mitre cuts.it will look like a u shape.should be strong enough. There is not a great load go through the back end.This all looks horribly familiar...

View attachment 104790

View attachment 104791

View attachment 104792

View attachment 104793

View attachment 104794

View attachment 104795

View attachment 104796

View attachment 104797

I feel your pain.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Yes it's a tricky one to get right. I had it spot on a one point but it still didn't look right...it's a good place to mount tanks as it helps keep some weight over the back end.No going back is there? I think I must have measured and re-measured had a dozen times before committing with the grinder.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

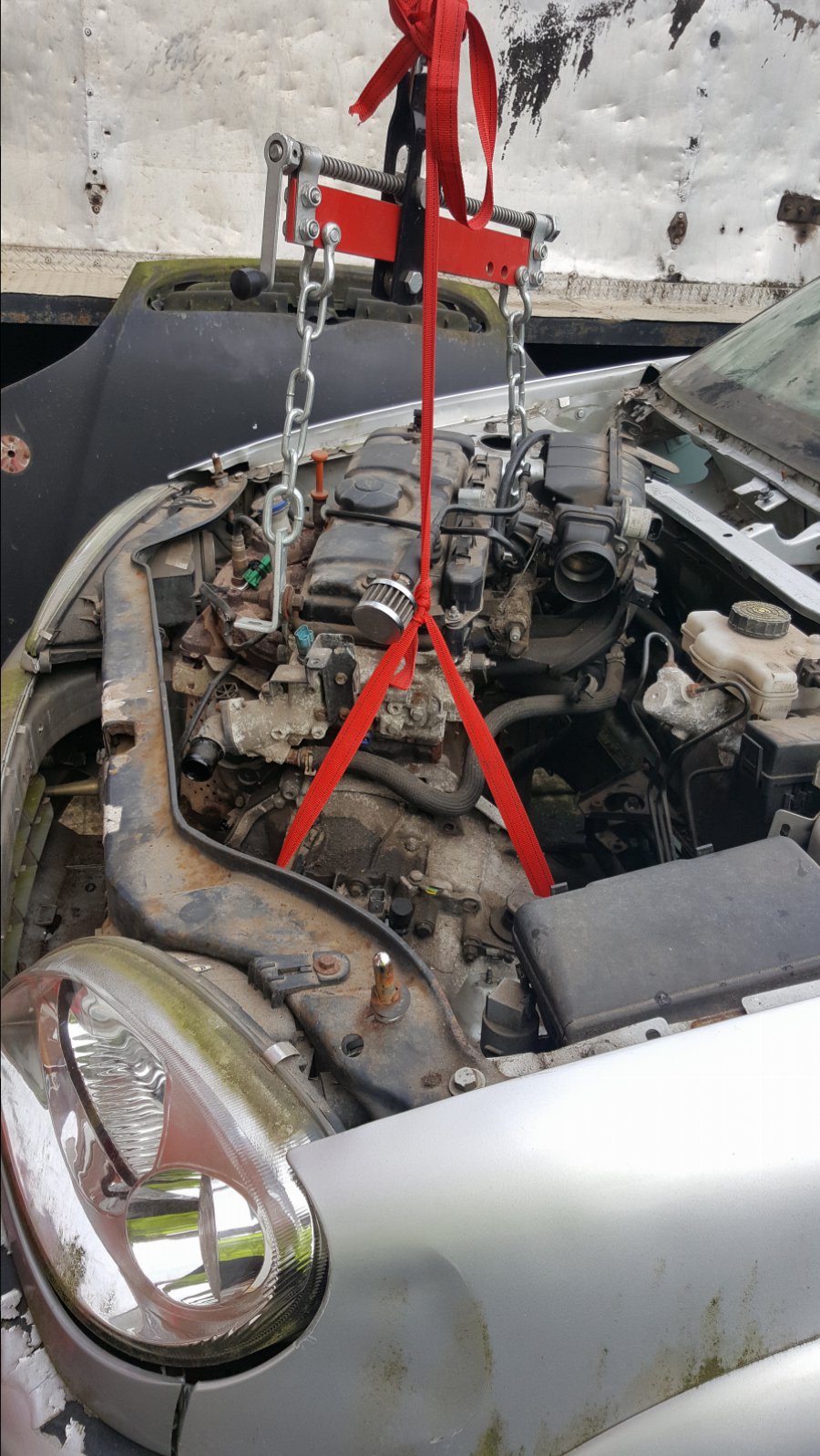

Been busy today..Engine and box removed and all associated parts....now I can see where necessary what needs attention...most of it....

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

I didn't achieve much yesterday apart from the joyful task of spot weld drilling...panel removal is time consuming and frustrating.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Painstakingly boaring Jim but needs must. A lot of corrosion between the seems...You're getting there mate, keep chipping away.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

I set about working out the radius of the inner arch..this will allow the use of 17 inch rims with the maxi arches..a tig rod was used as to get the shape.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Had a good day today...sunshine...plenty of tea...Mrs at work...joyfully...and managed to cut out the radius for the arch..and most of the inner wing....

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

A small amount of progress today...cut the last bit of the inner wing out...and then set about the task of clamping a couple of parts together just to see how it might look...

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Have not been able to get a lot done due to work..but managed a few bits.